- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China allen key set Manufacturers, Suppliers, Factory

Being a result of ours specialty and service consciousness, our corporation has won a very good status amid buyers all over the world for allen key set,wrench,torque wrench,impact wrench,allen wrench, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

allen key set, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, extensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

Hot Products

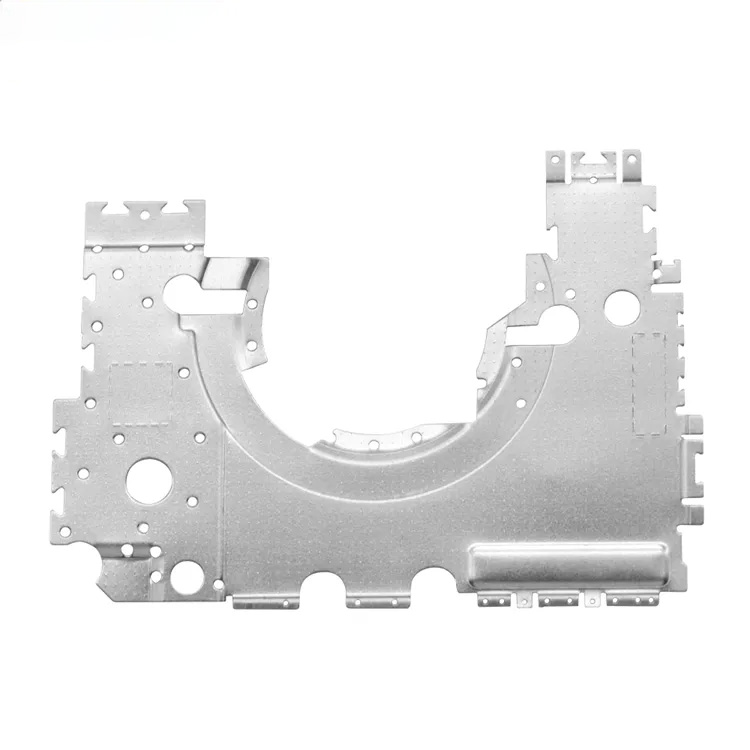

Motor Base

Xiamen Hongyu Intelligent Technology Co., Ltd. has always adhered to the business policy of production specialization, product branding, market internationalization, and global layout, and supplies Motor Base and other Precision aluminum casting to domestic and foreign markets and customers with high-quality products.

Product name: Motor Base

Application: Smart home, construction machinery, servo motor

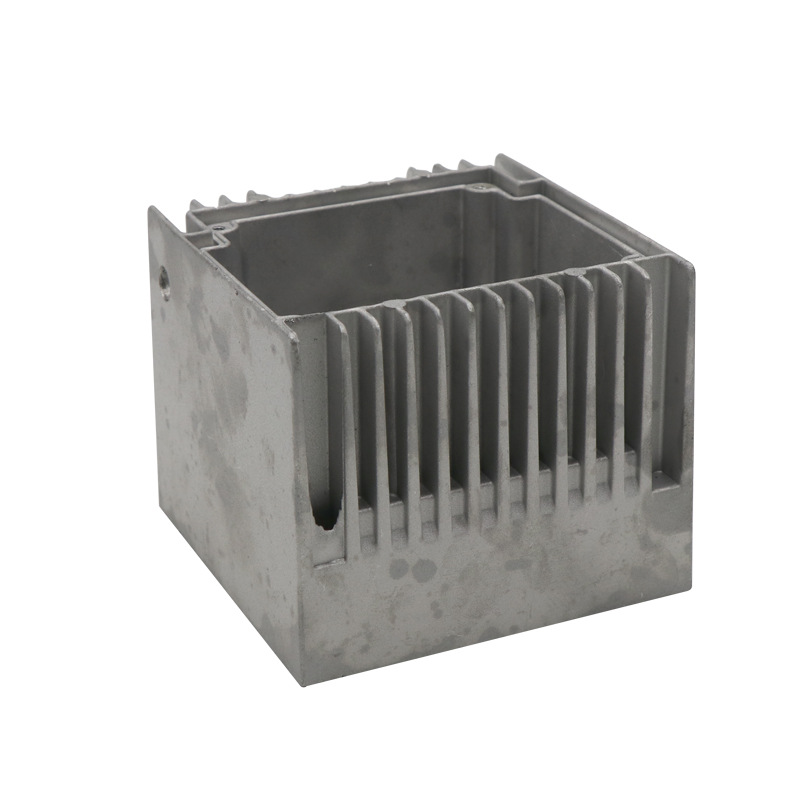

Customization: Support pricing processing servicesDie Casting Bearing Carrier Propeller

HY is a stamping manufacturing factory from China.A die casting bearing carrier propellerr in which two or more blades are connected to the hub, and the blade surface is a helical surface or an approximate helical surface.Stainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray Paintingscalpel blades

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional and reputable integrated manufacturing and trading company with many years of experience in various medical and laboratory fields. HY has established extensive and stable cooperative relations with many customers at home and abroad, with footprints in Europe, the United States, the Middle East and Russia, and can provide you with one-stop medical and laboratory product services.

Type: scalpel blades

Features: removable and replaceable, complete specifications

Material: carbon steel, stainless steelhospital screen

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional supplier of hospital screens, hospital beds (manual and electric), hospital stretchers, medical cabinets, hospital trolleys, maternity beds, cribs and other medical care products. HY has a mature import and export system and complete medical certification qualifications. Its current overseas markets include Europe, the United States, the Middle East and other regions.

Color: green, blue, pink, according to demand

Application: hospital, pharmacy, laboratory

Material: stainless steel, waterproof cloth, etc.

Roller: optionalmedical tweezers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steel