- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

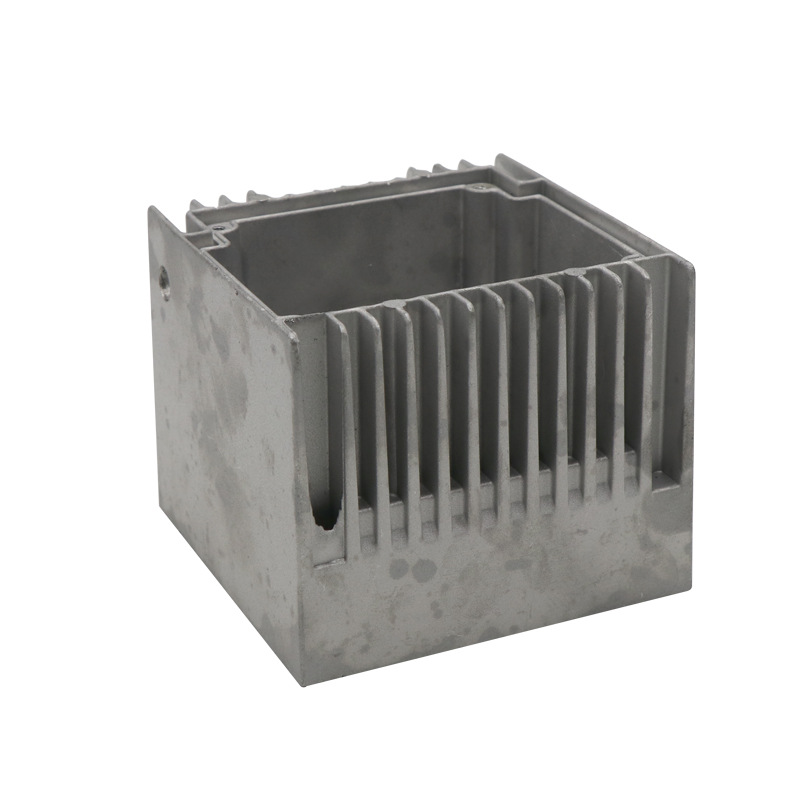

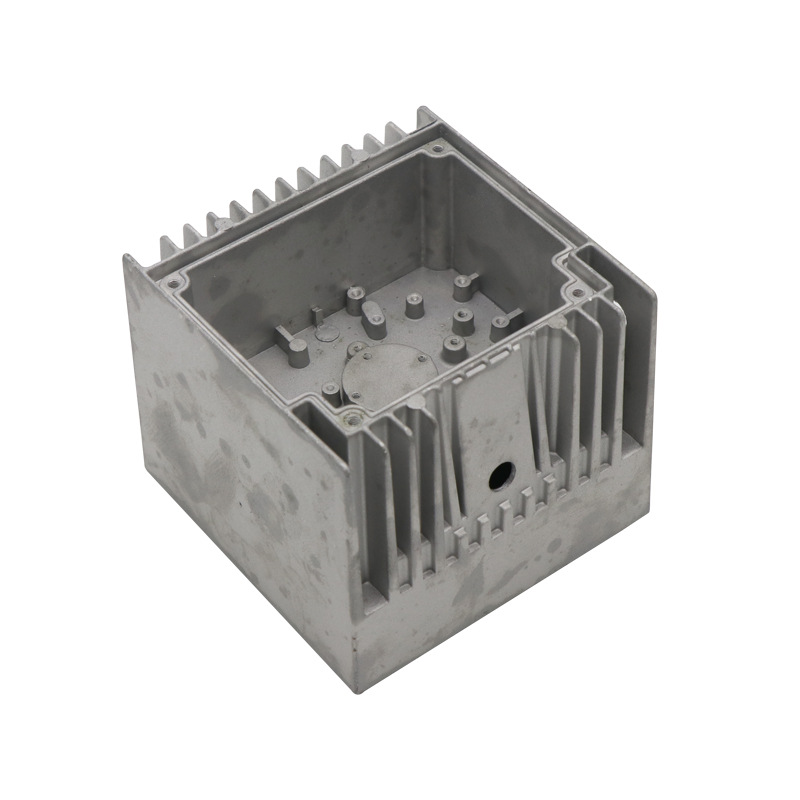

Heat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.

Send Inquiry

The cost of aluminum die-cast heat sink is mainly composed of die-casting molds, raw materials, machining and surface treatment. The mold cost is high, but it is suitable for mass production. The shape of die-cast radiators is more diverse than that of aluminum extrusion radiators, and the design is also more diverse.

|

Product name |

custom heatsink |

|

Material |

Aluminum alloy, copper |

|

Surface treatment |

Powder coating, anodizing, brushing, polishing, electroplating, powder coating, hot-dip galvanizing, electronic spraying, tinning, nickel plating, chrome plating, decoration, enamel spraying, etc. |

|

Processing method |

NC processing, stamping, die casting, welding, forging, mold making, etc. |

|

Shape |

Customization is supported |

|

Surface treatment |

Degreasing, (black) anodizing, sandblasting, painting, chromate treatment and laser marking, etc. |

|

Main application market |

IC circuit boards, motherboards, triodes, MOS tubes, TO-3P high-power tubes, radiators, electronic audio and video amplifiers, modules, LED lighting, inverters, welding machines, communication equipment, power supply equipment, electronics industry, thermoelectric coolers/generators, IGBT/UPS cooling systems, etc. |

The production process of radiator is to melt aluminum ingots into liquid, fill them into metal models, and directly die-cast them with a die-casting machine to make heat sinks. The die-casting method can make fins into various three-dimensional shapes. The heat sink can be made into complex shapes according to needs, or it can be made into heat sinks with diversion functions according to the fan and airflow direction. It can be made into thin and dense fins to increase the heat dissipation area. It is widely used because of its simple process.

Aluminum castings are produced from aluminum materials using aluminum die-casting technology. Aluminum is famous for its durability, high strength, corrosion resistance and wide use in custom-designed metal products.

As a professional heat sink supplier, HY has an independent mold design and manufacturing center. All molds are independently produced and continue to develop towards high technology and high performance. High-quality materials are selected, the structure is tight, multiple strict process inspections, and a professional design team are used to support customized production.

In which industries are heat sink used?

1. Computer Processor

Computer processors (CPU) generate large amounts of waste heat during operation. Featuring a copper heatsink with an active cooling fan. Allows the CPU to run more efficiently.

2. LED lighting

LED lamps generate a lot of waste heat when lighting, and small LEDs usually use passive heat sinks.

3. Electronic equipment

Electronics convert alternating current into direct current. During this conversion process, some waste heat will be generated, and long-term use will shorten the life of electronic equipment. Heat sinks on electronic equipment often use aluminum die-cast heat sinks

4. Automobile industry

In addition to heat sinks for vehicle control circuits, the role of the heat sink is to keep the electric motor cool during operation.

5.Aerospace

Heat sinks are commonly used in the aerospace industry on control equipment to transfer heat into the vacuum of space.