- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Progressive Stamping Mold Manufacturers, Suppliers, Factory

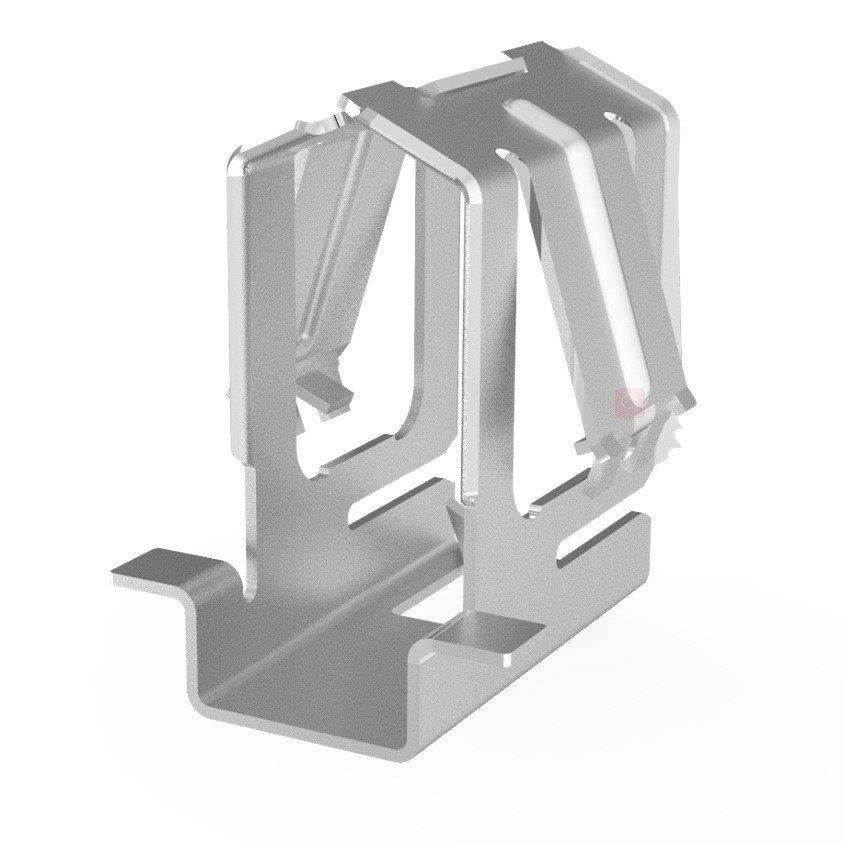

HY is a professional Progressive Stamping Mold supplier and progressive stamping die manufacturer in China. The progressive Progressive Stamping Mold is a stamping die with high efficiency, continuous and stable production. This kind of mold utilizes advanced processing technology and equipment and is characterized by precision, high speed and high automation. It can meet the mass production needs in sheet metal processing and can process high-quality, high-precision molded parts.

Compared with traditional stamping dies, progressive stamping dies have higher production efficiency, can reduce repeated operations and manual intervention, and greatly improve production efficiency. At the same time, because the specific steps of the mold are completed in a set of continuous strokes, the manufacturing cost and production cycle are relatively short. This not only improves production efficiency, but also reduces production costs.

The working principle of the progressive stamping die is to press a piece of sheet metal into a formed part. During the stamping process, the sheet metal is first cut, and then it enters the cutting die holes of the forming sequence, and is punched one by one. In this way, after multiple impacts, a complete formed part is finally formed. The entire stamping process is very precise and stable. Not only does there not be any waste, but the manufacturing of the mold can also be controlled very accurately. Therefore, progressive stamping dies have a very wide range of application prospects and market demands, and are an indispensable and important production tool for modern manufacturing.

HY Progressive Stamping Mold are exported to Europe, America, the Middle East, and Asian markets. In terms of quality, environment, management and safety, Hongyu has passed ISO9001, TS16949, and ISO14001 system certifications, fully ensuring the stability and consistency of product quality.

- View as

photovoltaic inverter

Xiamen Hongyu Intelligent Technology Co., Ltd. is a national key high-tech enterprise focusing on the research and development, production, sales and service of related components and accessories of renewable energy such as solar energy and wind energy, such as photovoltaic inverter. The company is currently the largest photovoltaic inverter manufacturer in China and has complete independent processing capabilities. The company's current full application scenarios cover users, distributed, and large ground/water surfaces.

Protection level: IP67

Type: pv inverter, solar and power inverter

Size: Customization supported

Material: aluminum, metal, stainless steel, aluminum alloy, galvanized steel

metal junction box

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of cable connectors and waterproof metal junction box. HY integrates R&D, production and sales. It focuses on shaping the PULTE brand and provides excellent technical performance, efficient quality assurance, satisfactory sales services and reasonable prices. Its products are widely used in various fields such as junction boxes, distribution cabinets, communication equipment, instrumentation, medical equipment, machine tools and machinery.

Thickness: 0.7mm-1.6mm

Product type: stainless steel junction box, metal j box

Color: silver, natural color, according to customer needs

Material: MS, SS, GAL, SGCC, ALU, brass

Surface treatment: spray painting \ powder coating \ electroplating \ polis......

solar panel mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that mainly manufactures photovoltaic modules and photovoltaic brackets. It mainly produces high-power 550-730 watt photovoltaic modules and photovoltaic brackets. HY is mainly engaged in the design and production of rooftop and ground solar photovoltaic installation solutions. Related products include stainless steel roof hooks, aluminum alloy roof brackets, aluminum alloy solar panel clamps, steel ground screws, etc.

Product type: solar panel mounting system, solar panel pole mountr

Processing services: stamping, die casting, bending, welding, punching, cutting

Material: aluminum alloy, stainless steel

Service life: 20-25 years

solar mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of solar photovoltaic support systems in the new energy industry. These products have been sold to more than 100 countries and regions including the United States, the European Union, Australia, the Middle East, South Africa, Japan and Southeast Asia, and have been recognized by customers at home and abroad. HY can produce according to national technical standards according to customer needs. All performance indicators meet national standards and can provide complete qualification certification documents. Providing customers with high-quality, cost-effective products and excellent after-sales service is our mission and commitment to customers.......

Read MoreSend InquirySolar Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a solar bracket manufacturer integrating scientific research, manufacturing, sales and after-sales service. Solar Bracket is manufactured using metal stamping technology, which is more economical and efficient while ensuring high precision and high quality, ensuring its durability, high strength and stability. Product name: solar panel brackets Color: natural color, black, customizable Service life: 25 years Warranty: 15 years

Read MoreSend InquiryHair Dryer Filter

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and has been providing high-quality Hair Dryer Filter to customers at home and abroad. The filter hair dryer we produce is light in weight, has good stability, and has good anti-oxidation filtration. It can effectively use manufacturing processes such as stamping and etching to save materials and reduce production costs. Material: 304 stainless steel, aluminum alloy, titanium, nickel-based alloy, etc. Specifications: Customizable Use scenarios: home, hotel, barber shop, etc.

Read MoreSend Inquiry