- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Die Casting Manufacturers, Suppliers, Factory

HY is a professional die casting supplier and die casting manufacturer in China. A die casting is a mold used to make metal castings, usually made of metal, gypsum, sand and other materials. Casting molds are widely used in modern manufacturing industries, including automobile manufacturing, machinery manufacturing, home appliance manufacturing and other fields.

Die casting offer many advantages. First of all, it can produce complex geometric shapes and high-precision castings, making the quality of castings more stable and reliable. Secondly, casting molds have high production efficiency and can produce castings of the same size and quality in large quantities, reducing production costs and improving production efficiency. In addition, die casting have a long service life and can withstand high-temperature and high-pressure environments, reducing breakdowns and repair costs during the manufacturing process.

The use of die casting requires high-precision production equipment and strict mold manufacturing standards, but it can also promote the improvement of manufacturing technology. It plays an important role in making the manufacturing process more refined and efficient, improving product quality and market competitiveness.

To sum up, HY die casting has many advantages and is an indispensable tool and technology in the manufacturing industry. Through technological improvement and innovation, the application of die casting will continue to expand and improve, promoting the development of modern manufacturing.

HY products are exported to Europe, America, the Middle East, and Asian markets. In terms of quality, environment, management and safety, HY has passed ISO9001, TS16949, and ISO14001 system certifications, fully ensuring the stability and consistency of product quality.

- View as

stroller frame for car seat

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, ......

motorcycle cylinder head

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer and exporter of motorcycle cylinder head. HY has a complete range of products, mainly motorcycle engine systems, including cylinder blocks, pistons, piston rings and cylinder heads, cams, rocker arms, crankshafts, connecting rods, main and secondary shafts, etc.

Material: Aluminum Alloy

Product Name: Motorcycle Cylinder Head

Proofing Service: Proofing Support

Accessories: Piston Kit, Gasket

Quality Inspection: 100% Full Inspection

Perfume Cap

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of high-quality perfume bottle caps. We provide high-quality caps for perfume bottles to customers at home and abroad. We will provide you with the best after-sales service and timely delivery.

Product name: Perfume cap

Special casting types:Metal mold casting

Surface treatment: electroplating

Material: zinc alloy

Molding process: gravity die casting

Tolerance: 0.02

Proofing cycle: 1-3 days

Gas Stove Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove bracket from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperature

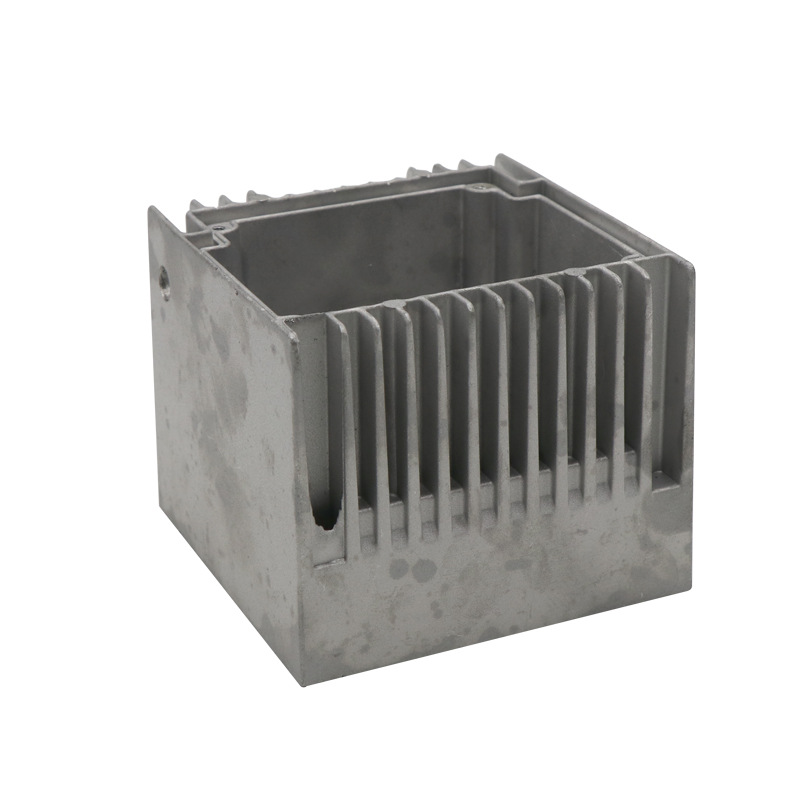

Heat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.

Read MoreSend InquiryEngine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 days