- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China impact wrench Manufacturers, Suppliers, Factory

Every single member from our large efficiency profits team values customers' requirements and organization communication for impact wrench,wrench,torque wrench,allen wrench,socket wrench, In addition, we would properly guideline the shoppers about the application techniques to adopt our products and solutions as well as the way to select appropriate materials.

impact wrench, We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

Hot Products

Stator And Rotor

Xiamen Hongyu Intelligent Technology Co., Ltd. can provide most products in the motor industry, such as stepper motors, DC brushless motors, servo motors, including stator and rotor, electric push rods and other related accessories. HY can customize products and production lines according to customers' industries, such as medical, industrial control, robots, robotic arms, etc.

Product name: rotor stator

Type: brushless motor

Torque: 0.3Nm

Certification: ISO9001, ISO14001, CE, ROHS, CCC

Customization: support customizationElectronic Metal

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in aluminum alloy and zinc alloy die-casting processing, and has 17 years of relevant processing experience. HY supports diversified comprehensive services from mold design, manufacturing, and production.

Processing service: Stamping electronic metal accessories

Customization service: Support customization, and can design solutions according to customer needs

Processing type: Metal forming

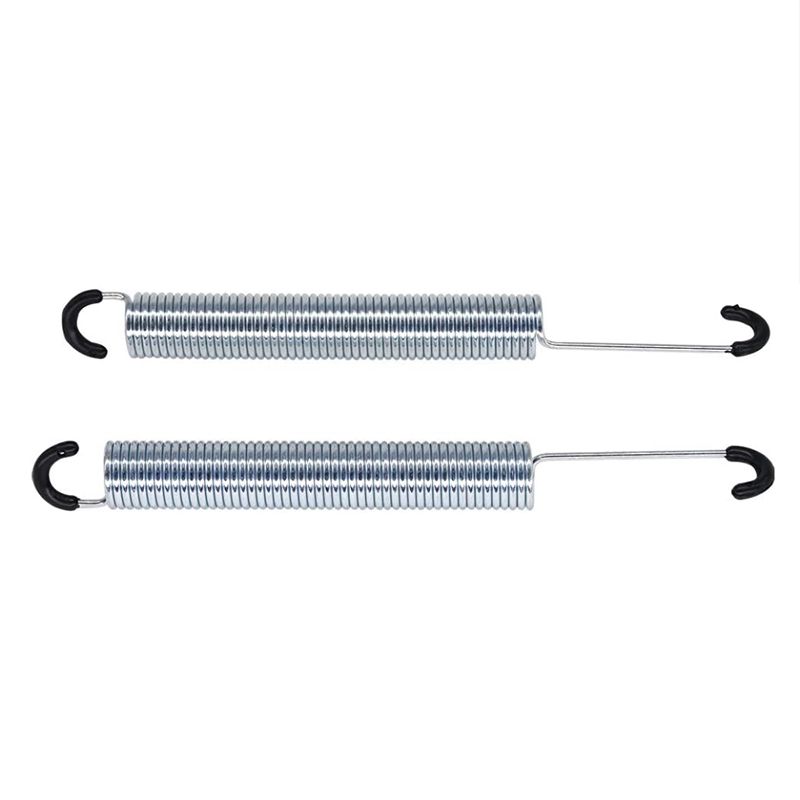

Tolerance requirement: ±0.02mmStamping Wire Formed Fasteners

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Precision Hardware Stamped Aluminum Plate

HY Precision Hardware Stamped Aluminum Plate specifications: 1. The HY precision metal stamped aluminum disc is made of aluminum with a thickness of 0.4mm. 2. This product is used in climate conditioners. 3. The product has high sealing performance and stability.Mobile Phone Holder

Stamping mobile phone holder material specifications: aluminum, copper, stainless steel and other materials

Material characteristics: Comply with ROHS, SGS testing, Proofing time: about 3 days

Mold opening time: about one week

Mold type: continuous moldbmw license plate frame

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in providing customers with local standard license plate frames, such as bmw license plate frame, American standard and European license plate frames, custom car plate frames, with 17 years of processing experience, can provide you with high quality and good service.

Material: metal, stainless steel, aluminum alloy, plastic

Application: auto parts, truck parts

Customized service: support customization