- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

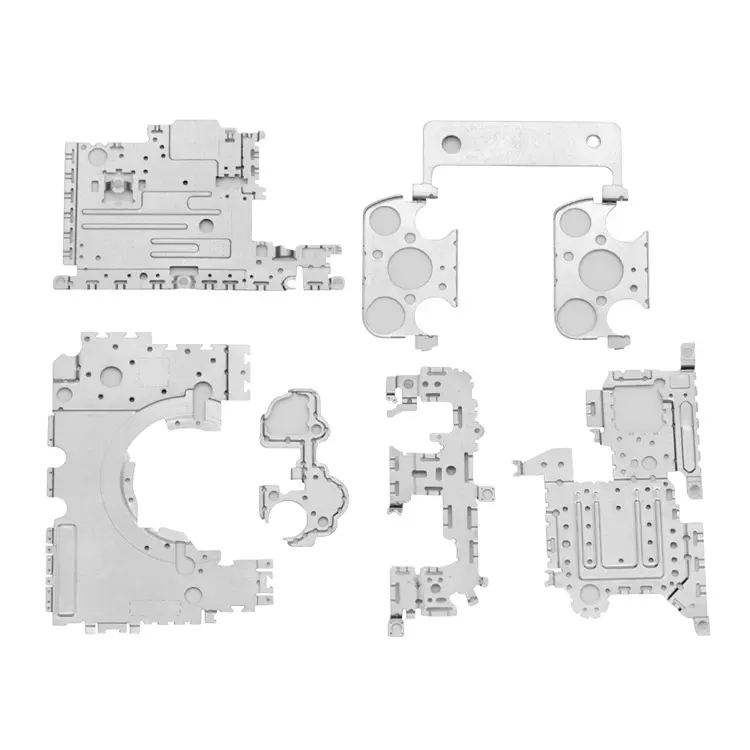

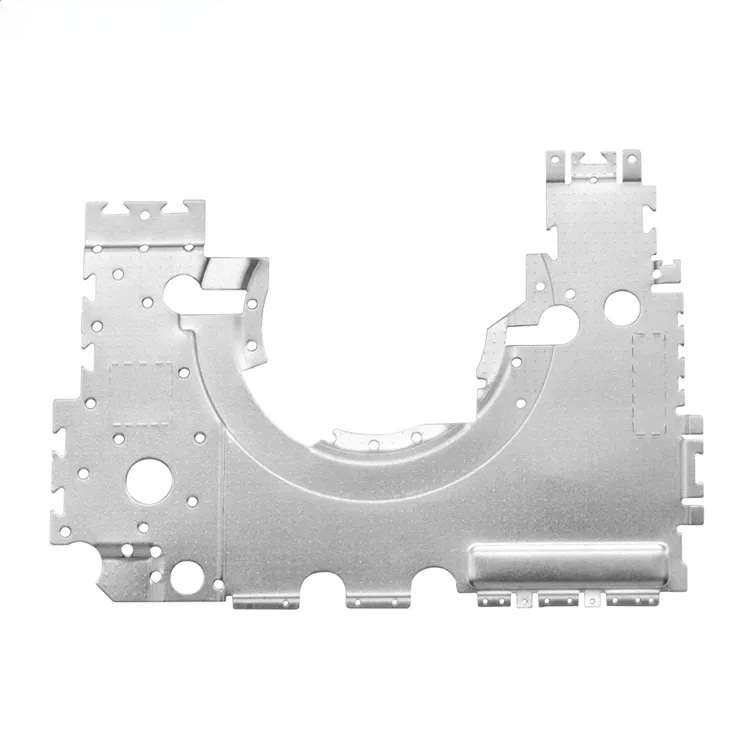

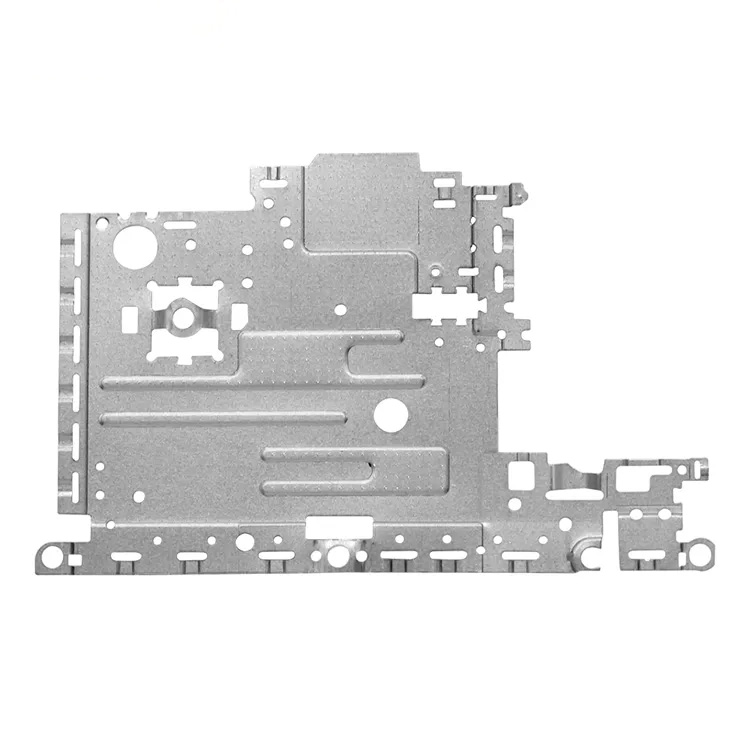

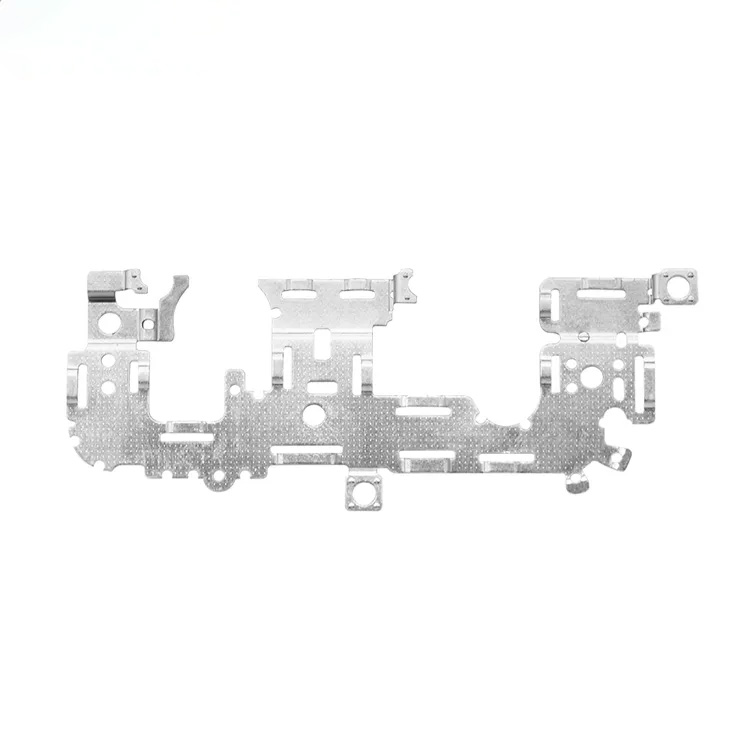

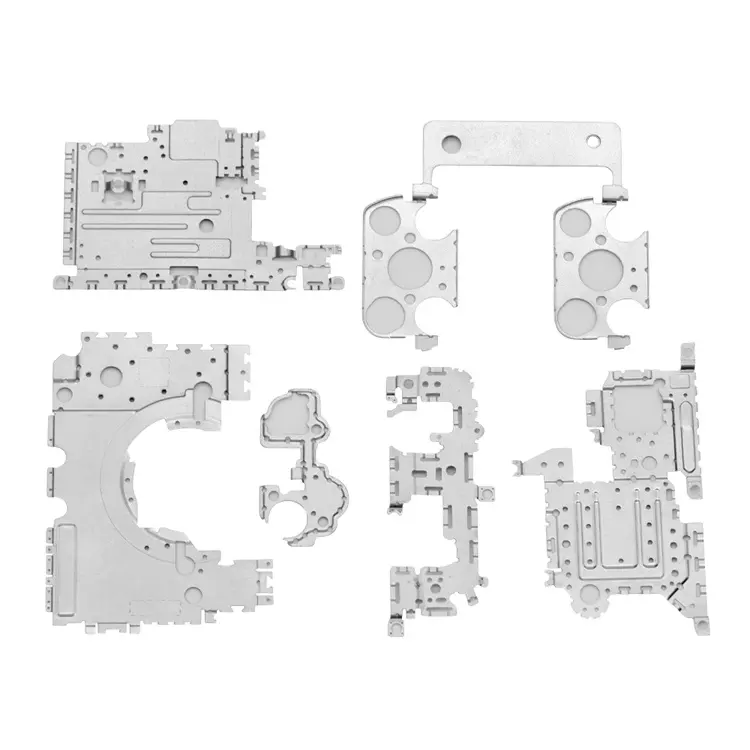

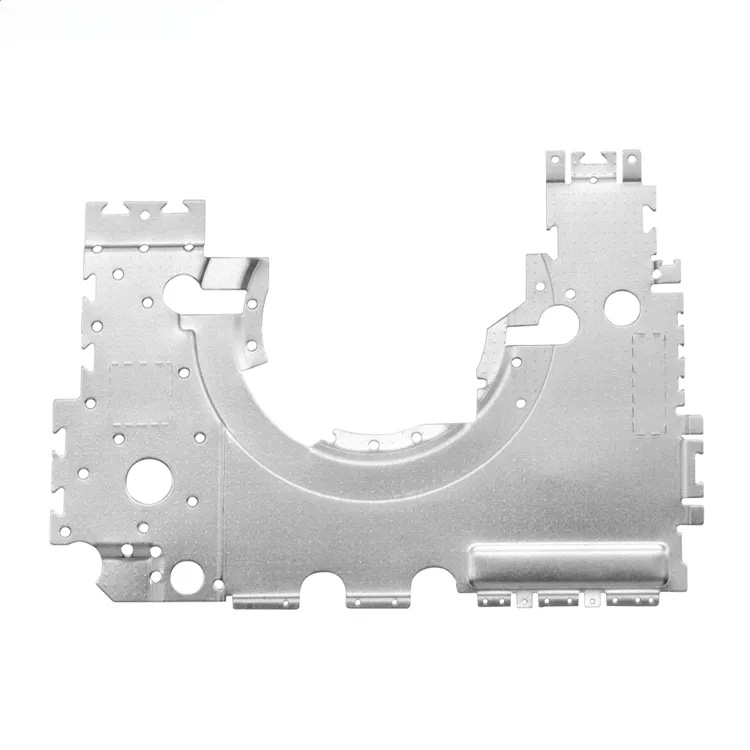

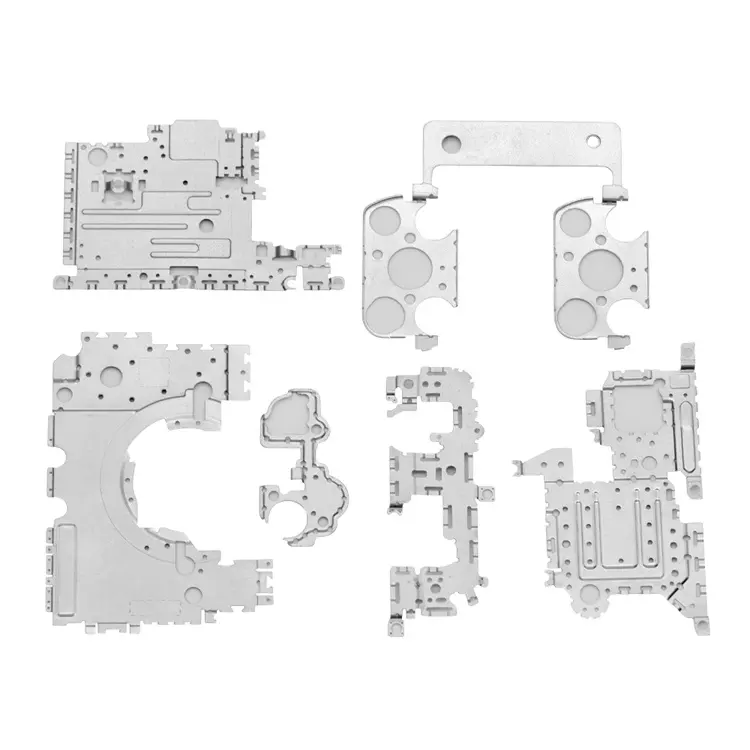

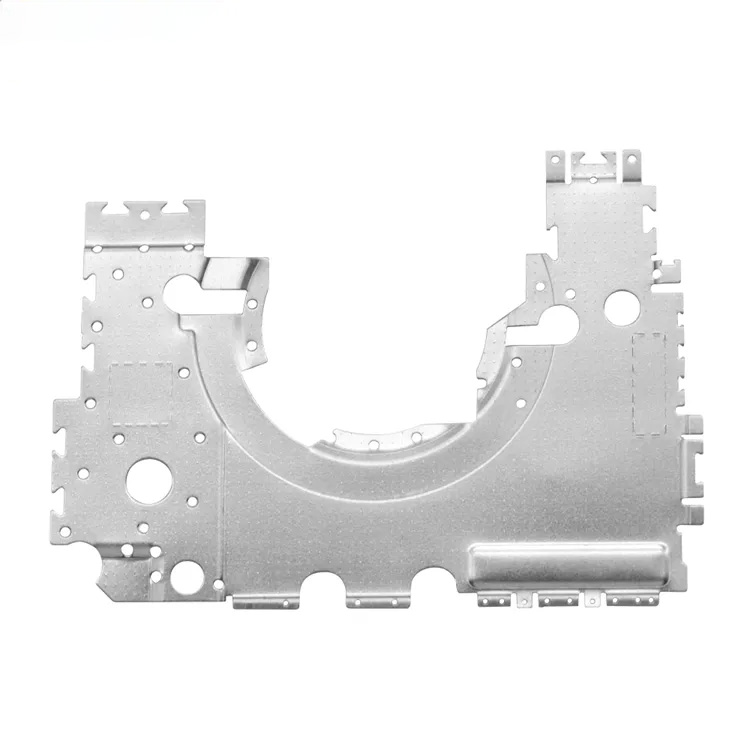

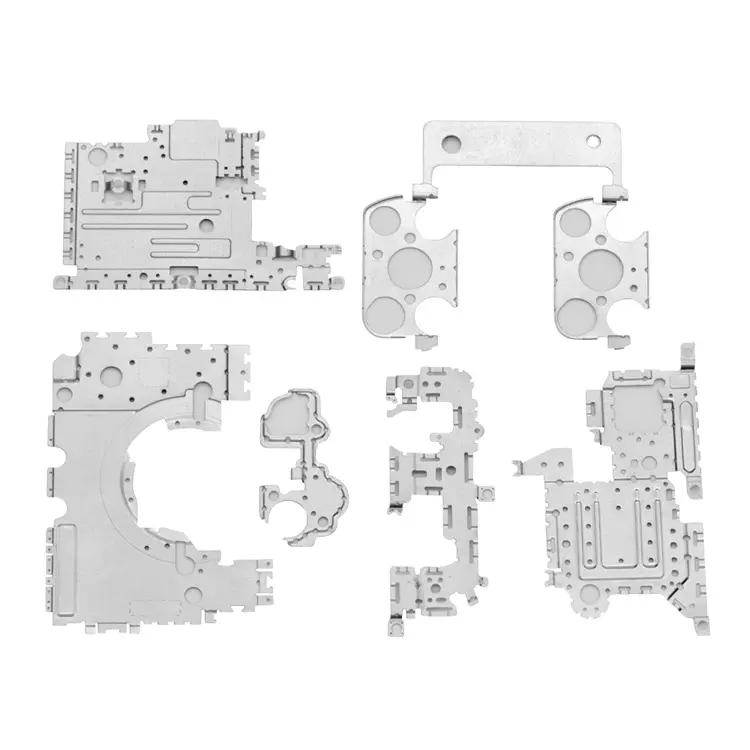

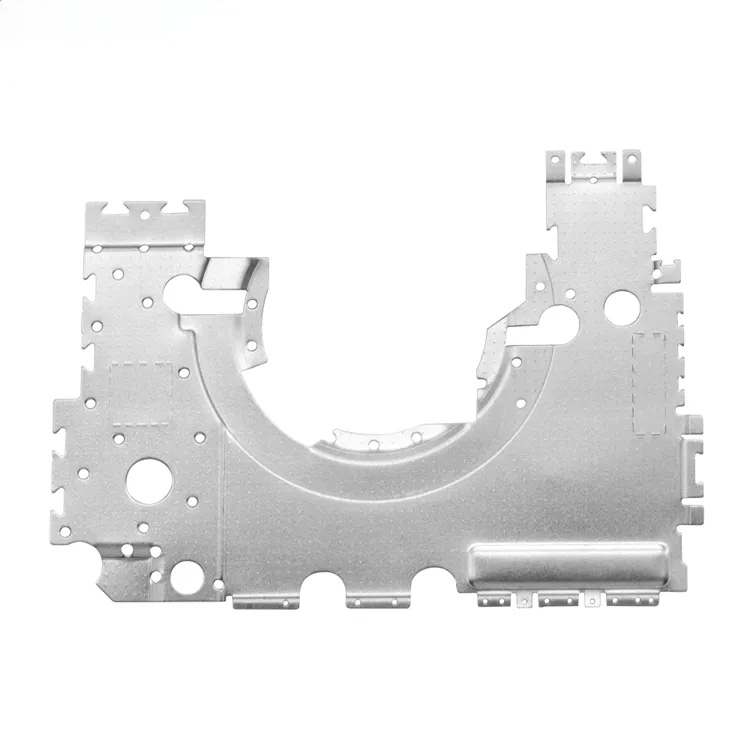

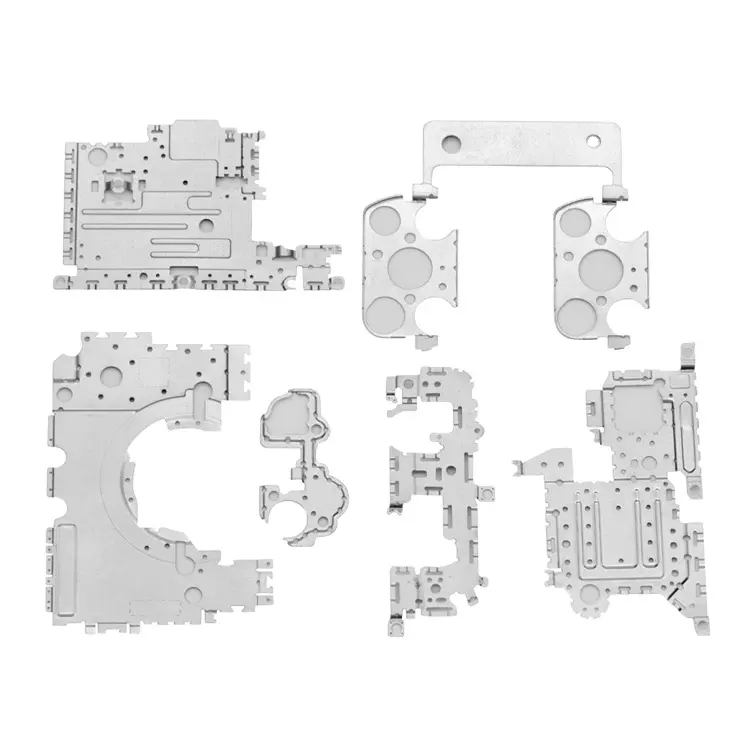

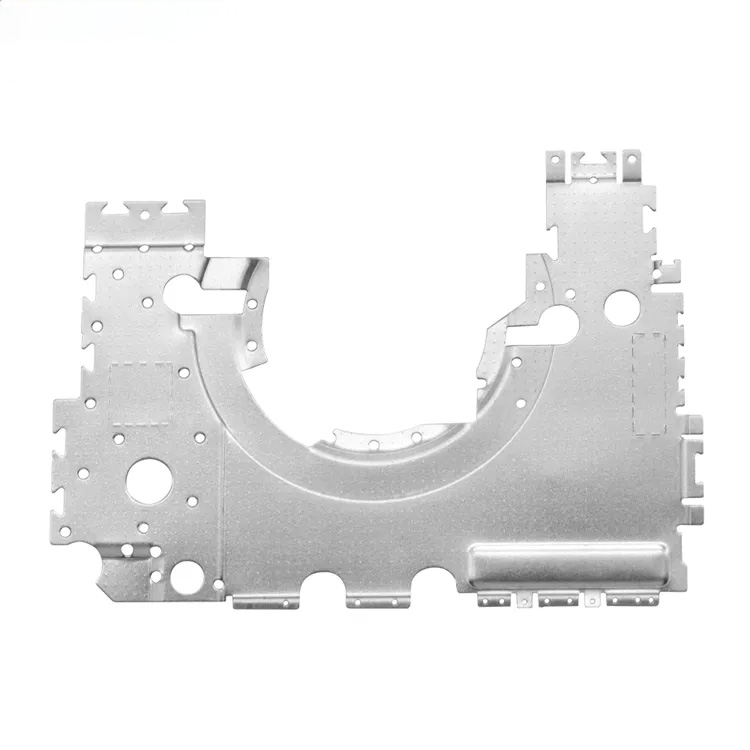

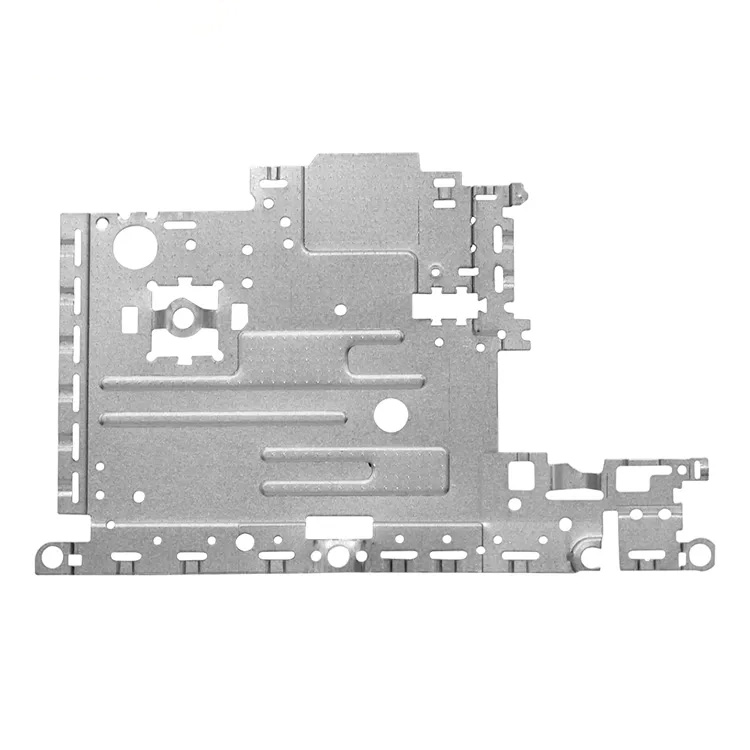

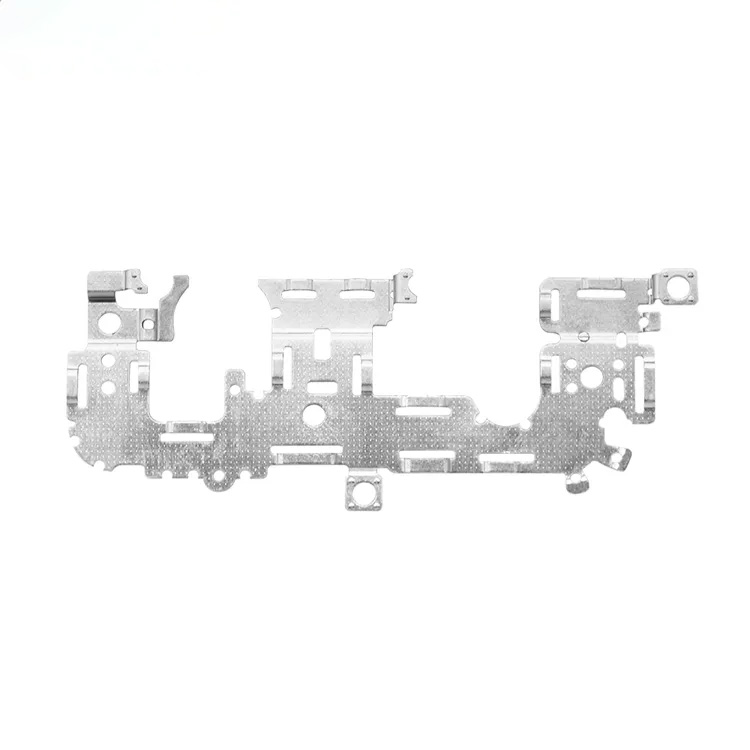

Mobile Phone Stainless Steel Stamping Parts

HY sixteen years of industry experience Material: SUS301 Mobile Phone Stainless Steel Stamping Parts specifications: customized according to customer requirements Material characteristics: complies with ROHS, SGS testing Qualification certification: ISO9001 & IATF16949

Send Inquiry

When the width of the punch is less than one material thickness, the punch is easy to break. In this case, HY has a wealth of solutions for stainless steel stamping parts for mobile phones.

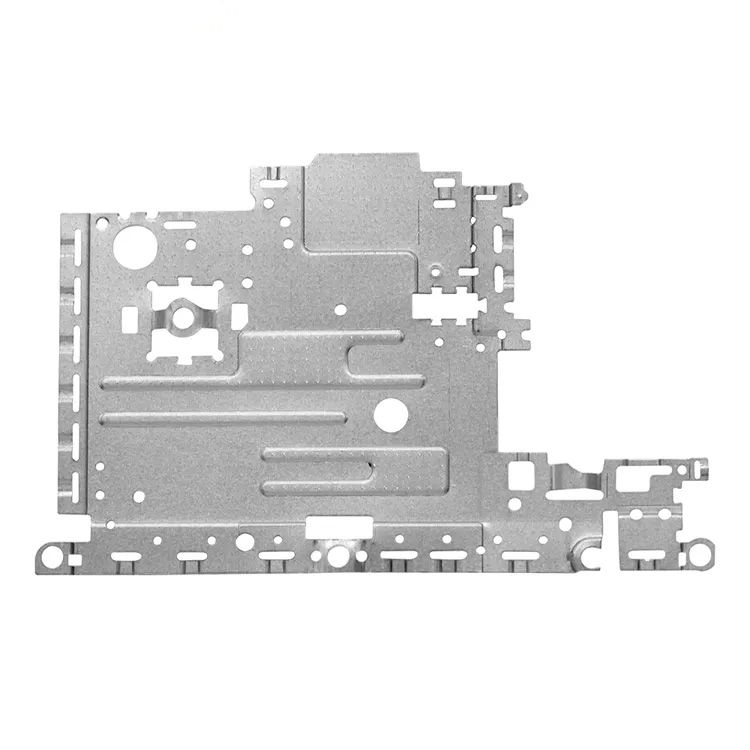

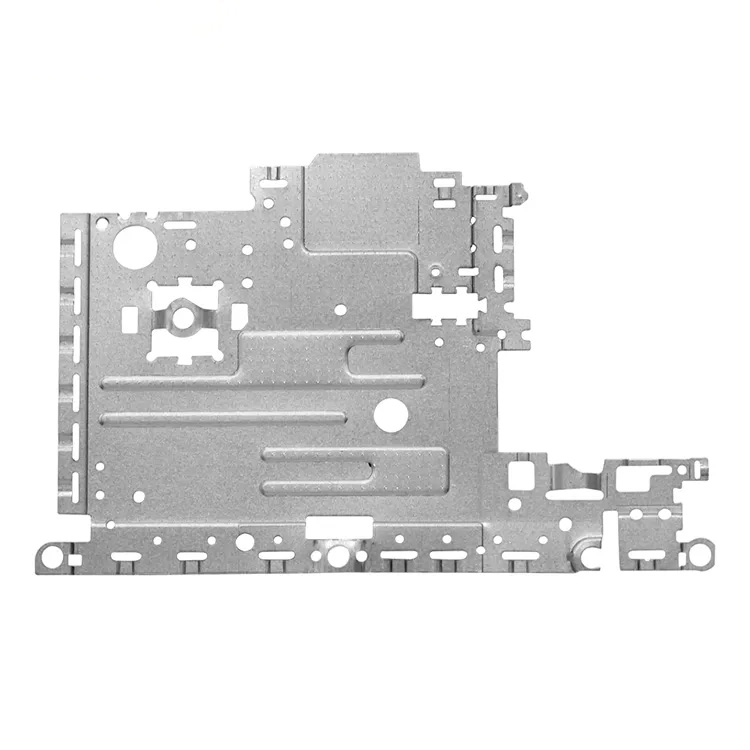

High-speed stamping, guaranteed production capacity

At present, HY's stamping speed can reach more than 1,000 times per minute, that is, a 16-cavity mold can produce 12.5KK mobile phone stainless steel stamping parts.

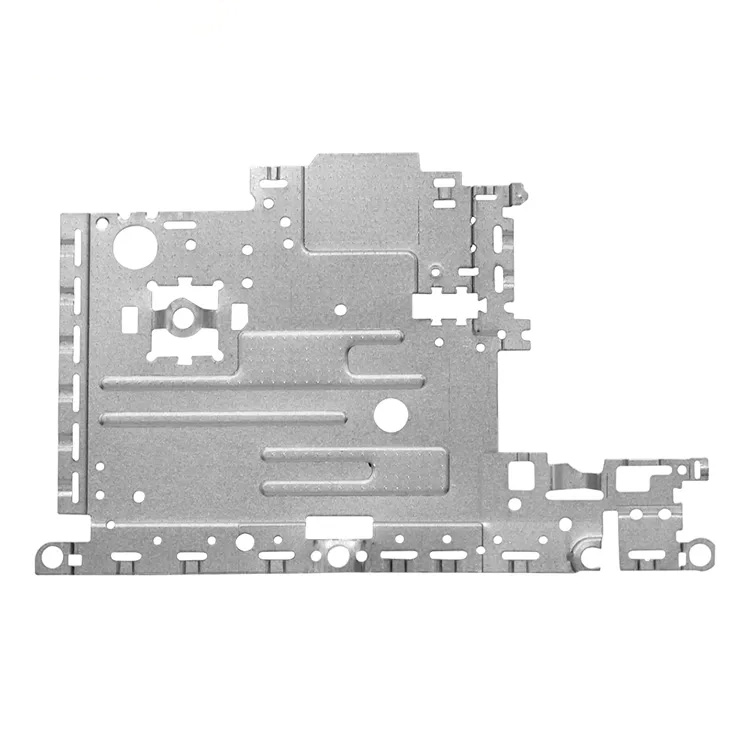

Small precision tolerance control

The tolerance of stainless steel stamping parts for mobile phones can reach +/-0.01MM. This tolerance places very high requirements on molds.

Smaller size and higher precision

The MINI-PCI step distance developed for mobile phone stainless steel stamping parts is 0.60mm

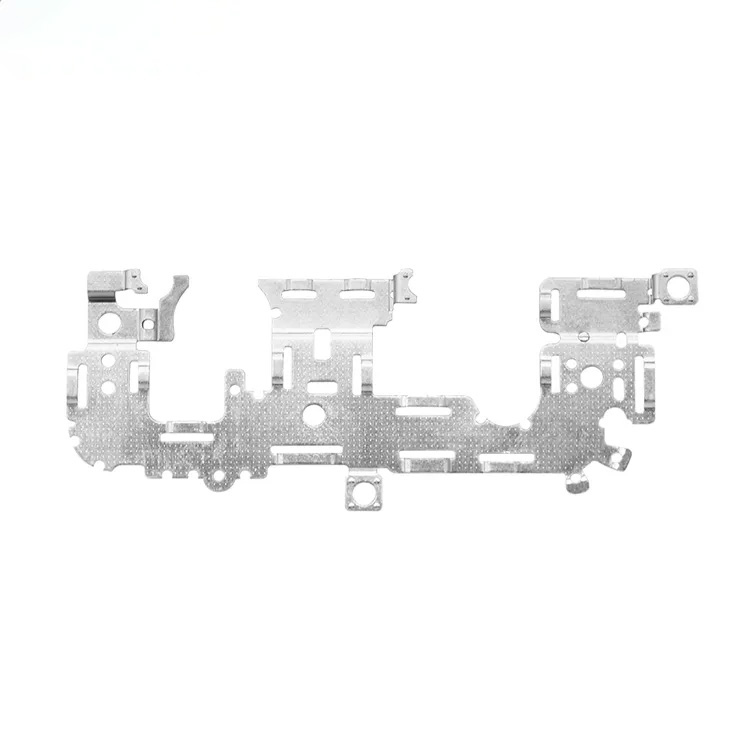

Can punch thin materials

It can process materials with a minimum thickness of 0.08mm. Processing such thin materials requires higher processing accuracy of the mold.

Can punch thicker and harder materials

The stainless steel stamping parts for mobile phones are made of high-quality mold steel and can process materials with a thickness of 0.8mm or more.

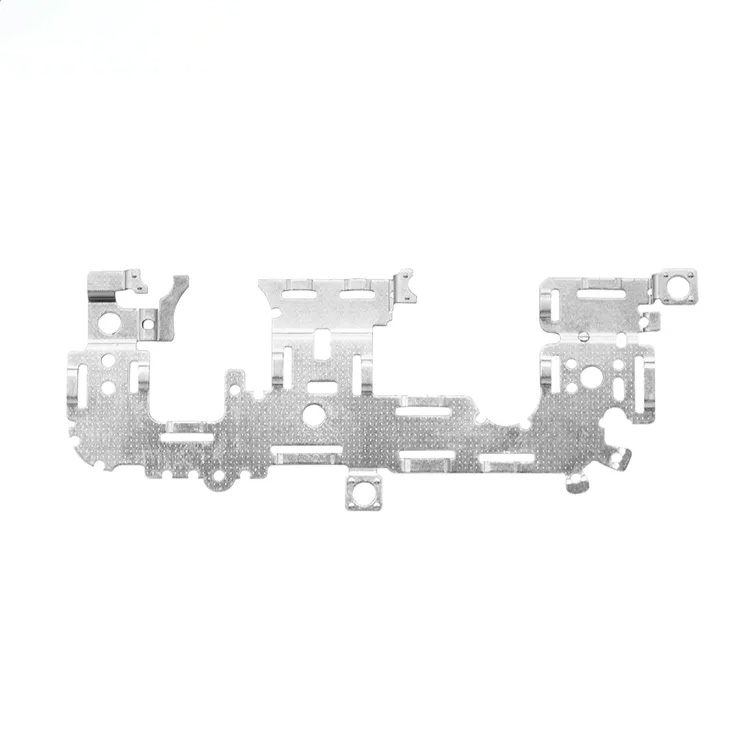

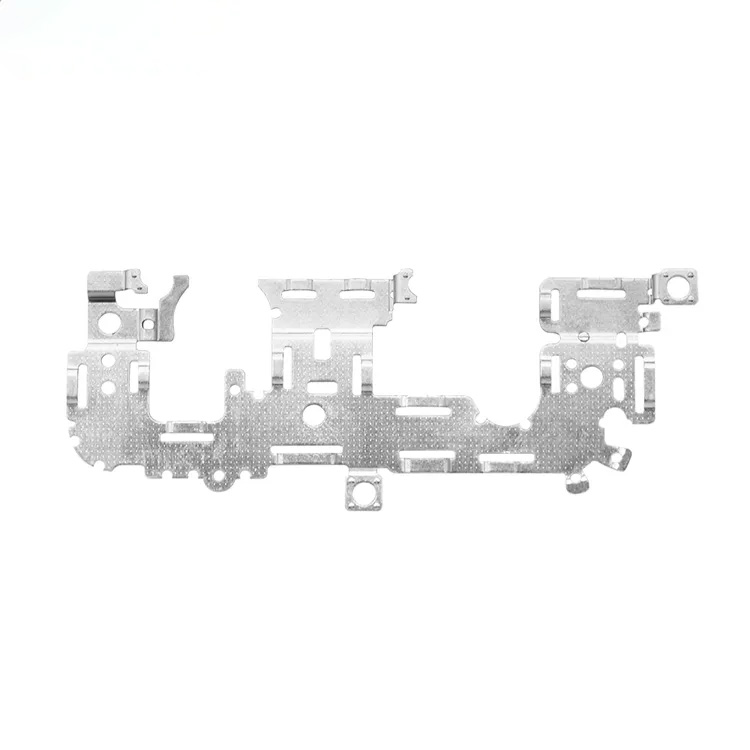

Exquisite craftsmanship and durability

For connectors, the better the smoothness of the contact surface, the smaller the impedance, the more durable the product, and the more stable the signal transmission. The surface gloss of the produced terminals reaches more than 95%.

Fine control of burrs, more stable conductivity

The stainless steel stamping parts produced for mobile phones can be controlled within 0.01mm, so that the gold-plated surface will not be scratched during contact between the plastic and the terminal during assembly, which is beneficial to the stability of conductivity.