- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

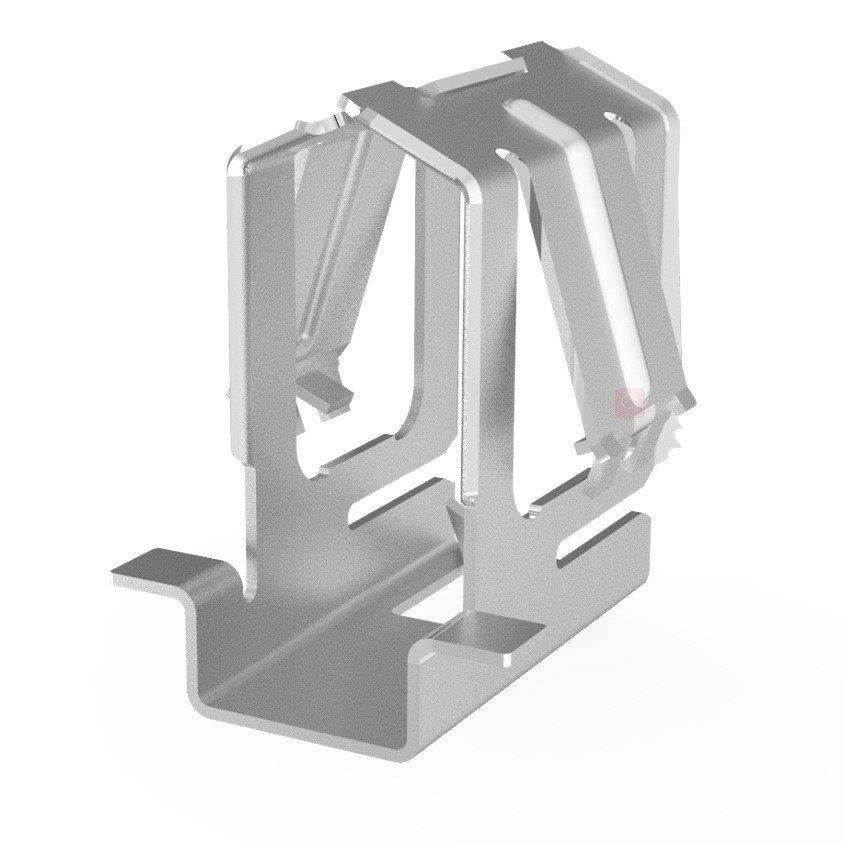

China Gravity casting Manufacturers, Suppliers, Factory

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Gravity casting,Aluminum casting manufacturers,Die casting companies,Die casting suppliers,metal bracket, For additional information and facts, please speak to us as quickly as possible!

Gravity casting, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

Hot Products

Stamping Wrench

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer and supplier specializing in the production of Stamping Wrench. Its main products include measuring tools, mechanical tools, fastening tools, clamping tools, etc. Impact wrench is an efficient and durable mechanical tool, widely used in automobile repair, home repair, aerospace and other fields. Its main advantages are easy to use and efficient, coupled with its high durability and reliability.

Material: 45 steel, 40cr, Q235, customizable

Surface treatment: galvanized, blackened, according to customer needs

Color: original metal color, customizable color selectionStamping Photovoltaic Terminals

Welcome to wholesale Stamping Photovoltaic Terminals from us,every request from customers is being replied within 24 hours. HY is a factory that specializes in customizing the production of photovoltaic terminal .The photovoltaic terminals of a photovoltaic system inverter are vital electrical connectors used to establish connections between the inverter and the various components of the photovoltaic (PV) system. They play an important role in ensuring efficient and reliable power transmission within the system.motor mount

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading manufacturing and processing plant with 17 years of processing experience and a mature import and export qualification certification system. We are committed to providing high-standard and high-performance high-quality motor mount auto parts, making us competitive in the global market.

Product type: motor mount

Quality: 100% professional quality inspection

Customization service: support OEM/ODM customizationCasting Clutch Components

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of Casting Clutch Components, covering an area of 12,000 square meters, equipped with machining centers, gantry CNC lathes, laser cutting machines, CNC bending machines and other equipment. The company has more than 70 skilled engineers and professionals. Products are exported to more than 30 countries including the United States, Mexico, Spain, Norway, Morocco and South Korea.

Product Type: Casting Clutch Components

Size: Customization supported

Quality Control: 100% full inspection

Certification: ISO9001/CE/ROHS, IATFBarbecue Grill

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business. Stamping type: metal stamping processing Grill material: stainless steel plate Processing type: metal forming Process: stamping, bending, trimming, forming, blanking Surface treatment: electroplating Proofing cycle: 8-15 daysStainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray Painting