- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

motor mount

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading manufacturing and processing plant with 17 years of processing experience and a mature import and export qualification certification system. We are committed to providing high-standard and high-performance high-quality motor mount auto parts, making us competitive in the global market.

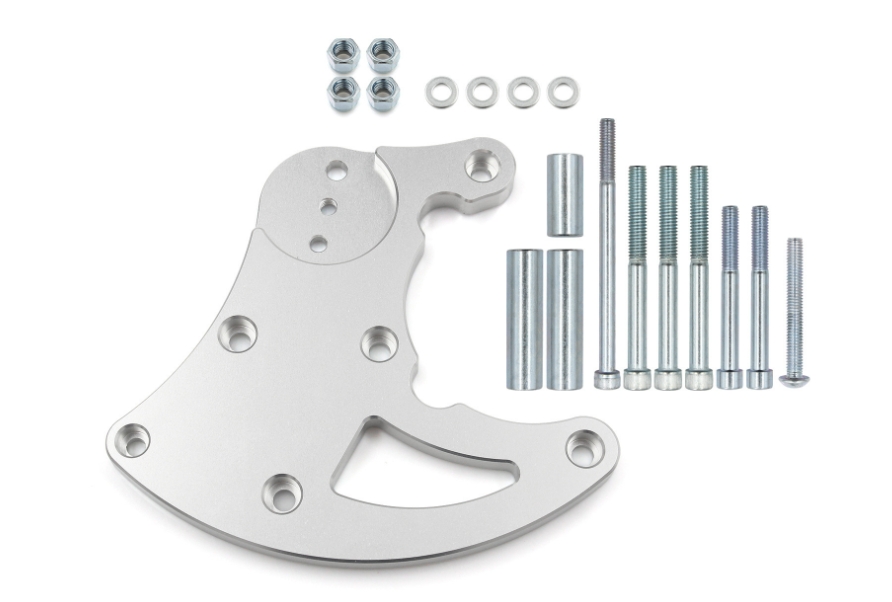

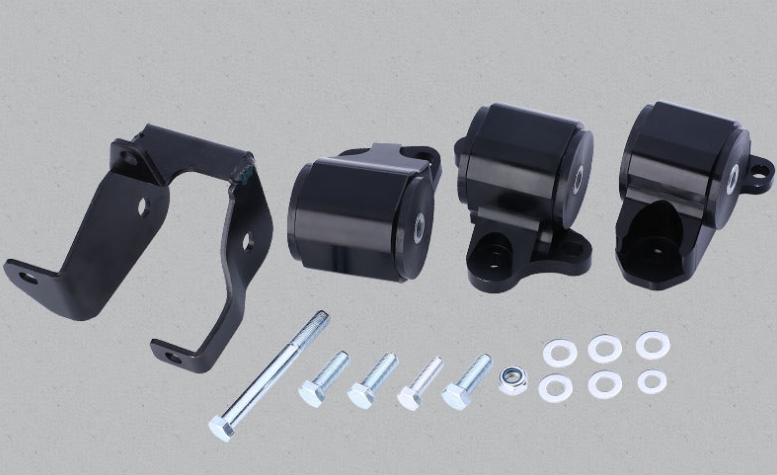

Product type: motor mount

Quality: 100% professional quality inspection

Customization service: support OEM/ODM customization

Send Inquiry

Introduction to Processing Technology

The motor mount is an important load-bearing structure in the automobile suspension system and is a connector between the engine and the body. It not only needs to support the weight of the engine, but also transmits the force and torque acting on the engine. Therefore, the suspension bracket requires sufficient strength, rigidity and service life. Ductile iron sand casting is usually used.

In the current context of the pursuit of lightweight automobiles, on the premise of meeting the mechanical performance requirements of the suspension bracket, the use of lighter aluminum alloys to replace ductile iron to produce suspension brackets is the main choice for current automobile processing.

As a professional engine mount bracket manufacturer, HY uses an extrusion casting process that fills the mold at a lower filling speed, so that the molten metal solidifies under high pressure to obtain a high-density casting that can be treated with solid solution aging. It is an advanced forming technology with broad application prospects. After using aluminum alloy instead of cast iron for processing, the quality can be reduced by 62.9% compared with the original, greatly reducing the dead weight.

|

Auto parts |

Engine brackets, suspension rubber parts, tie rod heads, front and rear axle bushings, upper and lower swing arms, bearings, shock absorbers |

|

Sizes |

Original standard, customizable |

|

Colors |

Silver, black, metallic |

|

Material |

Aluminum alloy, steel, rubber, cast iron |

|

Auto brands |

Mercedes-Benz, Nissan, BMW, Porsche, Volvo, etc. |

Product quality testing

The forming process parameters of aluminum alloy extrusion casting include extrusion pressure ratio, extrusion speed, pouring temperature, mold temperature, holding time, etc. The reasonable selection of forming process parameters has an important impact on the production of high-quality castings. In order to ensure the strength of use, all motor mounts produced by HY will undergo quality tests, including strength tests, X-ray detection of pores and fatigue tests.

Why choose HY

High quality assurance: We adhere to strict quality control protocols to ensure the reliability of our products.

Excellent service: Factory direct sales can directly connect with engineers, have mature foreign trade docking customer experience, and complete all work with the highest efficiency.

Customization: Tailor-made solutions can meet specific automotive parts requirements.

Reliable support: Our professional customer service team can answer any questions you have 24 hours a day.