- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

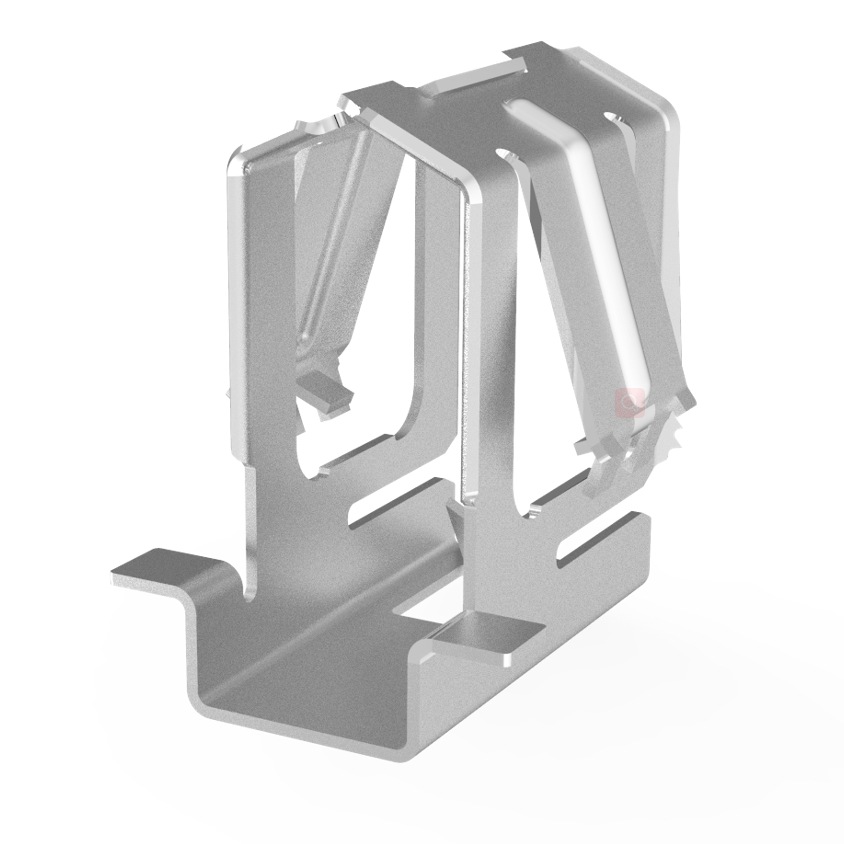

Solar Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a solar bracket manufacturer integrating scientific research, manufacturing, sales and after-sales service. Solar Bracket is manufactured using metal stamping technology, which is more economical and efficient while ensuring high precision and high quality, ensuring its durability, high strength and stability. Product name: solar panel brackets Color: natural color, black, customizable Service life: 25 years Warranty: 15 years

Send Inquiry

Widely used solar panel brackets

Solar panel mounting brackets are specially designed for solar systems and can accommodate a variety of panels, including 50W, 70W, 100W, 150W, 200W, 300W, 400, 500W and other specifications, suitable for enhancing solar installations installed on ships, houses, RVs, marine environments, etc.

|

Material |

Stainless steel, aluminum alloy |

|

Surface treatment |

Anodizing, hot-dip galvanizing, zinc-aluminum-magnesium |

|

Customization |

Customization is supported according to customer requirements |

|

Application areas |

Solar panel brackets |

|

Tilt angle |

15-30° |

|

Maximum wind speed load |

Up to 60M/S |

|

Maximum snow load |

Up to 1.4KN/㎡ |

|

Installation location |

Iron sheet, roof, caravan, boat, wall, plane, factory, metal surface |

If you have customized solar panel mounts for shingle roof, we need to know some basic information parameters of yours before that. The more information we have, the better we can serve you.

Information for designing and quoting solar panel mounts:

Part 1:

1. Which solar mount? Roof mount, ground mount or carport mount?

Part 2:

1. Solar panel size: __mm (length) x__mm (width) x__mm (thickness)

2. Layout of solar panels __ rows x__ columns, horizontal or vertical

3. How many panels do you want to install? __ quantity

4. Maximum wind load: __m/s or __km/h or __mph 5. Maximum snow load: __KN/m2 (if any)

Part 3:

1. Solar panel mounts for shingle roof

Roof type: tile roof, iron roof, asphalt shingle roof or other?

2. Suitable for flat roof mounting bracket/ground

Mounting bracket/carport mounting structure

3. Ground/roof clearance (height of the lowest end of the panel from the ground/roof floor): __mm

4. Solar bracket tilt angle: __ degrees

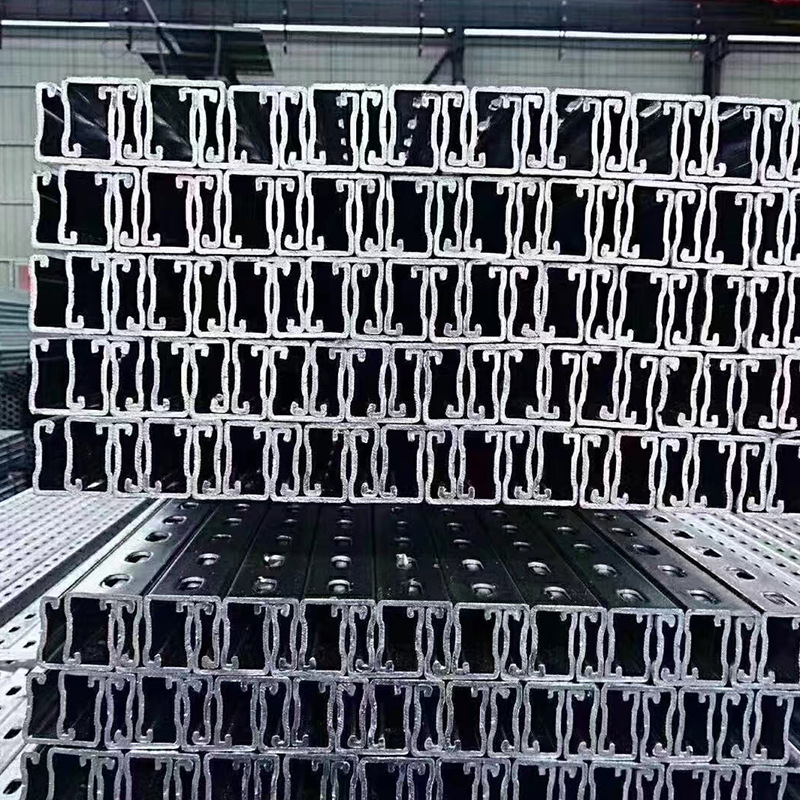

About our material selection

Choosing the most suitable material for your solar panel mounts is essential to ensure service life, performance and overall reliability. Using SGCC galvanized steel has many advantages, including durability, corrosion resistance, cost-effectiveness, sustainability and easy installation. By choosing SGCC galvanized steel, solar bracket manufacturers and installers can enhance the structural integrity of their installations, thereby improving efficiency and saving costs in the long term.

Advantages of Using SGCC Galvanized Steel Sheets for Solar Mounts

Durability and Weather Resistance

SGCC galvanized steel sheets are known for their excellent durability and weather resistance. The surface treatment galvanizing process forms a protective barrier on the surface, protecting the steel surface from moisture, corrosion and adverse weather conditions. This ensures the longevity and structural integrity of the solar panel roof mounts, giving them a long service life in harsh conditions.

Anti-corrosion

One of the main advantages of SGCC galvanized steel is its excellent corrosion resistance. The zinc coating acts as a sacrificial layer, preventing the underlying steel from coming into direct contact with corrosive agents. As a result, the brackets are protected from rust, oxidation and other forms of corrosion, even when exposed to moisture or extreme weather conditions, which is extremely important for high latitudes and areas with complex climate change.

Cost-effectiveness and Efficiency

SGCC galvanized steel sheets provide a cost-effective solution for solar panel mounting brackets. Their durability and corrosion resistance minimize the need for frequent repairs or replacements, saving costs in the long term. Additionally, the galvanizing process is highly efficient, providing even coverage and optimal protection of the steel surface, ensuring reliable performance throughout the life of the equipment.