- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Crimp Connectors

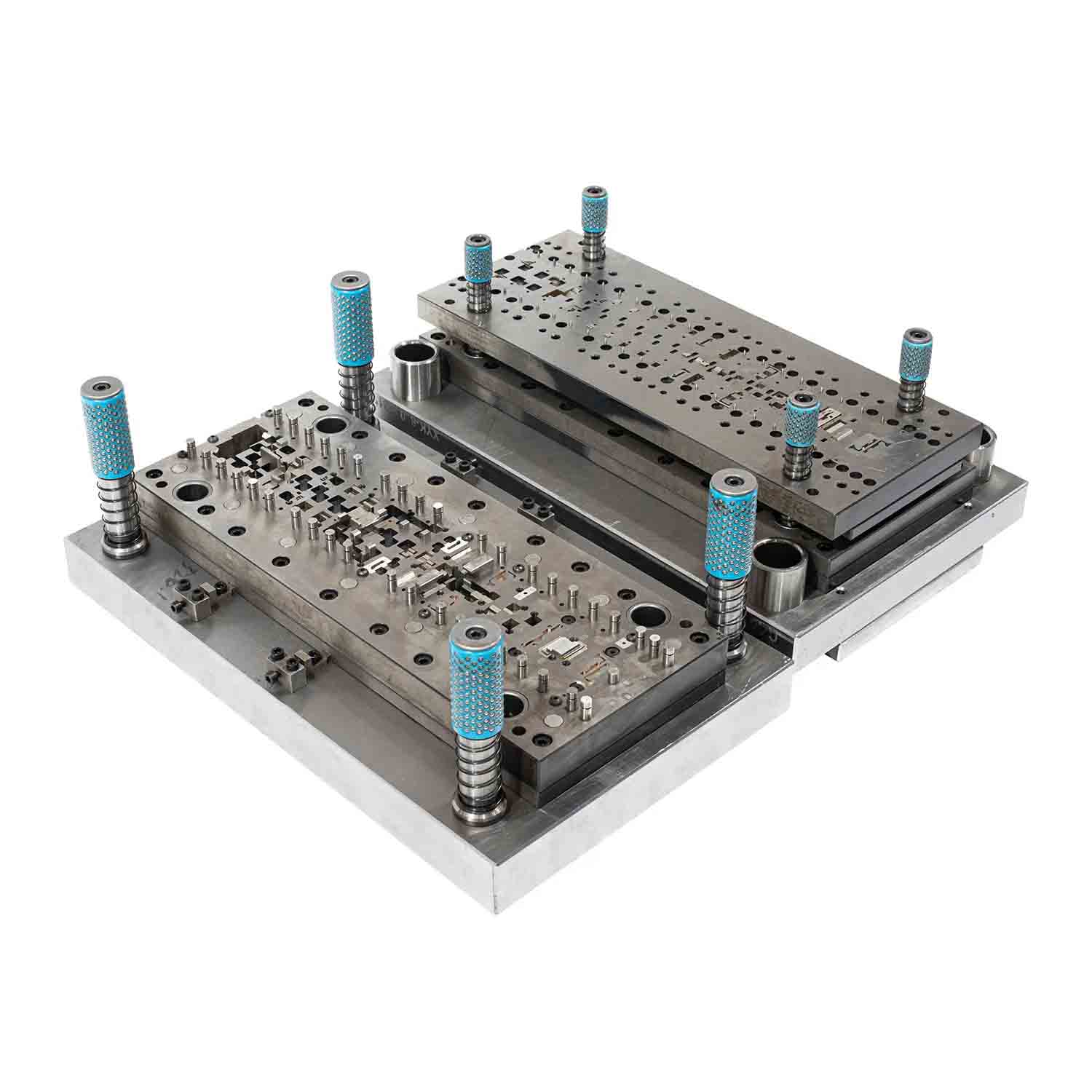

Xiamen Hongyu Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Hongyu's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precision

Send Inquiry

How to Check the Crimp Status on Crimp Connectors

The crimp quality of crimp connectors is a key factor in ensuring the final interconnect performance. We can judge whether the crimp condition is good by the following situations, including: whether the terminal stamping is damaged, the terminal stamping is not bent, the insulation in the terminal window but the wire crimp is not insulated, the insulation crimp does not pierce the wire, the edge crimp is correctly included, the brush is visible after the wire is crimped, the brush is not in the connection area, whether there is a tapered hole, and the micrometer across the insulation crimp is in the tolerance window.

It is necessary to check whether the Stamping hardware terminals are correctly crimped. Whether you crimp by hand or machine, you need to carefully check each connection. Incorrect crimping will greatly shorten the service life of crimp connectors and even be a safety hazard.

Because each type of connector and specification has a different thickness tolerance, the thickness measurement of the wire crimp can be used as a reference indicator. Incorrect thickness not only shortens the life, but may even cause the connection to be unstable and fall apart quickly, eventually causing losses.

How to make a good crimp

Whether the crimping state is ideal can directly affect the durability of use, especially in harsh environments.

First of all, we should make it clear that all connectors are suitable for a small range of wire sizes.

Inappropriate sizes of selected wires and crimp connectors will lead to poor electrical performance and insufficient mechanical strength, which will eventually lead to reduced durability.

A small amount of wear or contamination on the crimping die can also cause problems with crimping, but since there are many types of crimping, we need to explain different methods according to different situations.

|

Product type |

Stamping hardware terminals |

|

Quality certification |

ISO 9001, RoHS, REACH |

|

Material |

Brass, phosphor bronze, bronze (customizable) |

|

Surface treatment |

Nickel plating/galvanizing/tin plating/gold plating/silver plating, etc. can be customized according to your requirements |

|

Application scenarios |

Automobiles, machinery, electric control boxes, smart homes, computers, industrial equipment, etc. |

HY processing technology

Technical requirements for electrical terminal block, spade terminal, crown spring, banana plug and other types:

1. The main material is mainly brass H62 without specific requirements, and the material of the crown spring drum spring is mostly beryllium copper;

2. Electroplating standard: Not all materials can be covered with gold plating, so before gold plating, a layer of nickel will be plated as above to ensure the effect of gold plating. The conventional specification standard of nickel-based gold plating is that the thickness of nickel plating is 50~80u, the thickness of gold plating is ≥2u, and the purity of gold used in plating is ≥99.8%. Apply solid film protective agent.

3. The surface of the product should be smooth, without oxidation to ensure practicality, and without burrs to ensure that the product will not loosen due to the uncompressed burr interval.

4. Hardware should not have tool marks, clamp marks or sharp edges to ensure product quality.

5. HY high-precision quality requirements, unspecified tolerance is ±0.02.

Standard specifications for terminal stamping material selection requirements:

1. Material: brass, phosphor bronze, bronze, custom materials are supported under special circumstances, thickness is usually 0.2, 0.25, 0.3, etc.;

2. The female end opening cannot be skewed, and the male end round head cannot be twisted to ensure product quality;

3. The arc of the 1M material strip cannot exceed 5mm;

4. The surface of all Crimp Connectors cannot be crushed, deformed, or oxidized;

5. All marked tolerances are the key control dimensions;

Specifications for electroplating:

1. Appearance requirements: no oxidation, yellowing, blackening, bluing, purple, hooking, high and low feet, etc.

2. Electroplating performance requirements: full nickel base 50u”-80u”, gold plating 1u”, measuring point double-sided 3mm;

3. It needs to be subjected to 260 degrees high temperature, and there is no discoloration, blackening, yellowing, blistering, shedding and other adverse phenomena within 5 seconds;

4. Tin plating performance test is required, and the tin plating coverage rate is above 95%;

5. Salt spray performance test is required, the salt water concentration is 5%, and it lasts for 24 hours in an environment with a temperature of 35℃, without oxidation and blackening and other adverse phenomena;

6. It is necessary to do a peeling test: there is no peeling phenomenon of the coating on the curved surface;

7. Product electroplating must comply with green environmental protection ROHS requirements.

8. All measuring points and part of the measuring surface are electroplated according to the measuring point requirements (the measuring point part is generally the key part of tin plating and conduction)

Why Choose HY

High-quality materials: Our PCB terminals are made of high-power pure copper, ensuring excellent conductivity and durability.

Precise dimensions: With an accuracy of up to 0.08 mm, these electrical terminals can perfectly fit electronic devices such as automobiles, machinery and home appliances.

Multi-purpose: This product can be used in a variety of customer-specified applications, including electrical control boxes, computers and other electronic devices.

Customizable surface treatment: The terminals can be nickel-plated, zinc-plated, tin-plated, gold-plated, silver-plated, etc. according to customer requirements to ensure compatibility with different devices.

Compliance with international standards: Our PCB terminals are ISO 9001:2015 certified, providing customers with quality and reliability assurance.