- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Cold Forging Fasteners Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our enhancement strategy for Cold Forging Fasteners,Metal Stamping Suppliers,Stamped Fastener,Custom Metal Stamping Services,Precision Metal Stamping, In our efforts, we already have many shops in China and our products have won praise from customers worldwide. Welcome new and old customers to contact us for the future long term business relationships.

Cold Forging Fasteners, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent for you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Hot Products

Hair Dryer Filter

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and has been providing high-quality Hair Dryer Filter to customers at home and abroad. The filter hair dryer we produce is light in weight, has good stability, and has good anti-oxidation filtration. It can effectively use manufacturing processes such as stamping and etching to save materials and reduce production costs. Material: 304 stainless steel, aluminum alloy, titanium, nickel-based alloy, etc. Specifications: Customizable Use scenarios: home, hotel, barber shop, etc.subframe

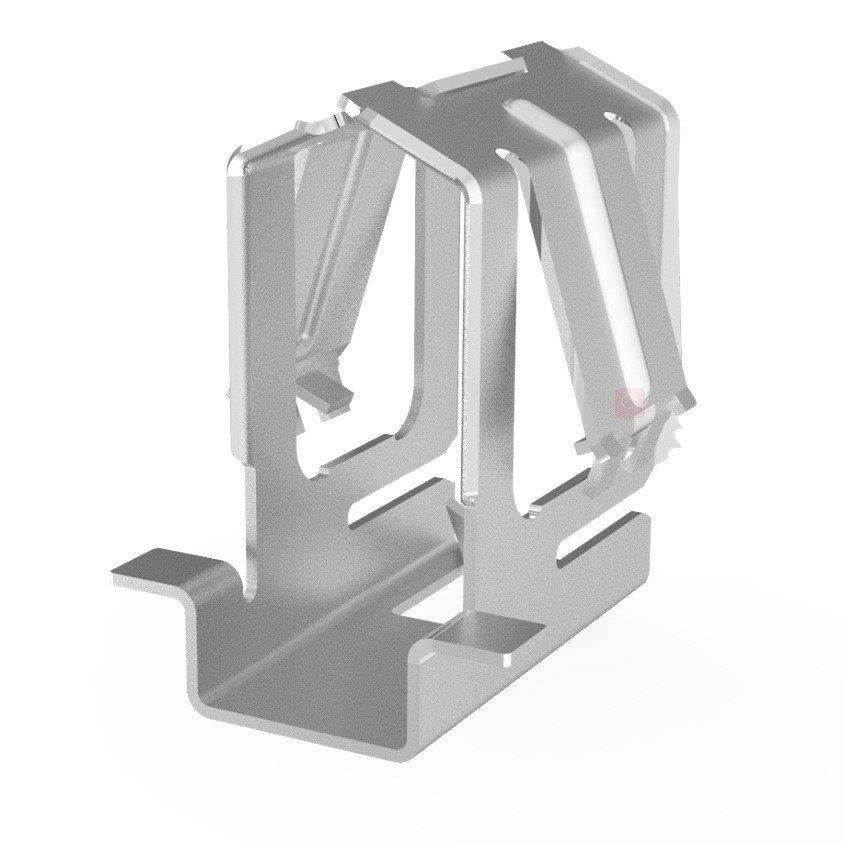

Xiamen Hongyu Intelligent Technology Co., Ltd. is committed to providing high-quality and reliable subframe cars to customers around the world. Since its establishment, HY has made it its first goal to provide customers with excellent services and products. Our business scope covers parts for various types of automobiles, ensuring that we can provide customers with the latest and most advanced products.

Product Status: Brand New

Product Name: Subframe

Material: SteelSolar Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a solar bracket manufacturer integrating scientific research, manufacturing, sales and after-sales service. Solar Bracket is manufactured using metal stamping technology, which is more economical and efficient while ensuring high precision and high quality, ensuring its durability, high strength and stability. Product name: solar panel brackets Color: natural color, black, customizable Service life: 25 years Warranty: 15 yearsCrimp Connectors

Xiamen Hongyu Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Hongyu's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precisionDie Casting Bearing Carrier Propeller

HY is a stamping manufacturing factory from China.A die casting bearing carrier propellerr in which two or more blades are connected to the hub, and the blade surface is a helical surface or an approximate helical surface.Metal Medical Stamping

HY is a well-known manufacturer of Metal Medical Stamping in China. Nearly 20 years of experience in manufacturing stamped medical parts.HY is a well-known manufacturer of stamped metal medical parts in China.