- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China precision metal stamping Manufacturers, Suppliers, Factory

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is "100% client fulfillment by our product high-quality, price tag & our staff service" and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of precision metal stamping,stamping small parts,miniature metal stamping,small part metal stamping,stamping parts, Initial enterprise, we understand each other. Additional enterprise, the trust is getting there. Our firm usually at your service anytime.

precision metal stamping, So far our solutions have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We've 13years specialist sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality merchandise and excellent service.

Hot Products

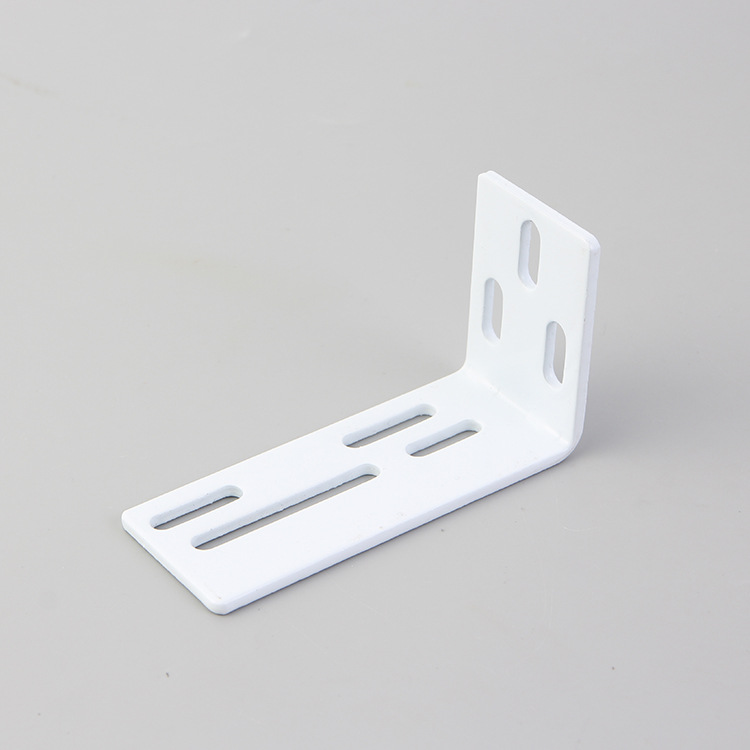

Curtain Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional Stamping Curtain Bracket Supplier, using precision metal stamping technology, good quality and low price.

Product name: curtain bracket

Material: stainless steel

Process: Progressive stamping die

Type: Hardware metal stamping

Industry: hangers, brackets, curtainsDie Casting Heat Sink

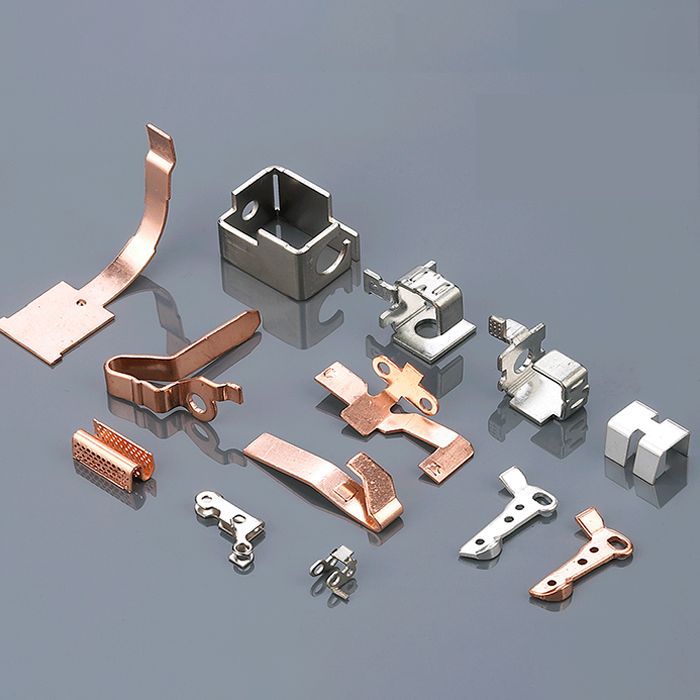

Die casting heat sink use a casting process where molten metal is forced into a molded cavity under high pressure. The molding cavity for a heat sink is created using a hardened tool steel mold that is carefully machined into a pre-specified shape.Selective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。Drive Shaft Assembly

Xiamen Hongyu Intelligent Technology Co., Ltd. integrates R&D, production, sales and after-sales service. Its main products include automobile drive shaft assembly (commonly known as: drive shaft), automobile constant velocity joint (commonly known as: cv joint), cv joint dust cover repair kit. In order to provide more convenient and faster service, we always reserve a large number of hot-selling models at home and abroad.

Product Name: Stamping Drive Shaft Assembly

Origin: Fujian, China

Application: Drive Shaft Connecting Parts

Special: Welcome To Customize OEM/ODM

Certificate: IATF16949, ISO14001, SGS RoHSshower chair for disabled

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company specializing in the production and sales of bathroom and medical care series products, with more than 17 years of processing experience. HY is proficient in global standards, focusing on the production of high-quality products, with a strict process system and quality inspection system to ensure product quality and delivery time. It has now covered the United States, Europe, Australia, the Middle East and other countries. We welcome global customers to establish cooperation.

Color: Black/Silver/White/Gray/Customized

Usage: Shower chair for disabled

Material: High-quality PE and thickened aluminum alloy pipe

Application scenarios: Bathroom, Hospital, OtherCasting Turbine Component

Hongyu is a manufacturer of Casting Turbine Component. Turbines are composed of various components that work together to convert the energy of high-temperature, high-pressure airflow into mechanical energy.