- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China black metal electronic Manufacturers, Suppliers, Factory

abide by the contract, conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for black metal electronic,metal electronic,Stamping electronic metal accessories,Shrapnel,Stainless steel shrapnel, We warmly welcome buddies from all walks of everyday living to hunt mutual cooperation and build a more brilliant and splendid tomorrow.

black metal electronic, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality items and good after-sales services. Up to now, our solutions have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Hot Products

hospital beds for home

Xiamen Hongyu Intelligent Technology Co., Ltd. is a modern high-tech enterprise with more than 17 years of processing experience and import and export trade experience. HY has developed a series of intelligent products, including manual beds, electric beds, nursing beds, wheelchairs and other products, using advanced die-casting stamping and automated welding technology, adhering to the concept of high quality, high precision and high efficiency throughout every production link. We welcome customers from all over the world to establish long-term cooperative relations.

Product type: hospital beds for home use

Material: medical grade steel + ABS

Application scenarios: hospitals, homes, clinics, wards, nursing homes

Customization: support OEM/ODM customizationDrive Shaft Assembly

Xiamen Hongyu Intelligent Technology Co., Ltd. integrates R&D, production, sales and after-sales service. Its main products include automobile drive shaft assembly (commonly known as: drive shaft), automobile constant velocity joint (commonly known as: cv joint), cv joint dust cover repair kit. In order to provide more convenient and faster service, we always reserve a large number of hot-selling models at home and abroad.

Product Name: Stamping Drive Shaft Assembly

Origin: Fujian, China

Application: Drive Shaft Connecting Parts

Special: Welcome To Customize OEM/ODM

Certificate: IATF16949, ISO14001, SGS RoHShospital screen

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional supplier of hospital screens, hospital beds (manual and electric), hospital stretchers, medical cabinets, hospital trolleys, maternity beds, cribs and other medical care products. HY has a mature import and export system and complete medical certification qualifications. Its current overseas markets include Europe, the United States, the Middle East and other regions.

Color: green, blue, pink, according to demand

Application: hospital, pharmacy, laboratory

Material: stainless steel, waterproof cloth, etc.

Roller: optionalMetal Brand Seal

Customized Metal Brand Seal, mirror polished, solid brass HY designs a unique seal taste for you. The iconic "shiny" head is machined from a solid brass blank and coated with an ultra-fine ceramic layer.Custom Metal Stamping Dies

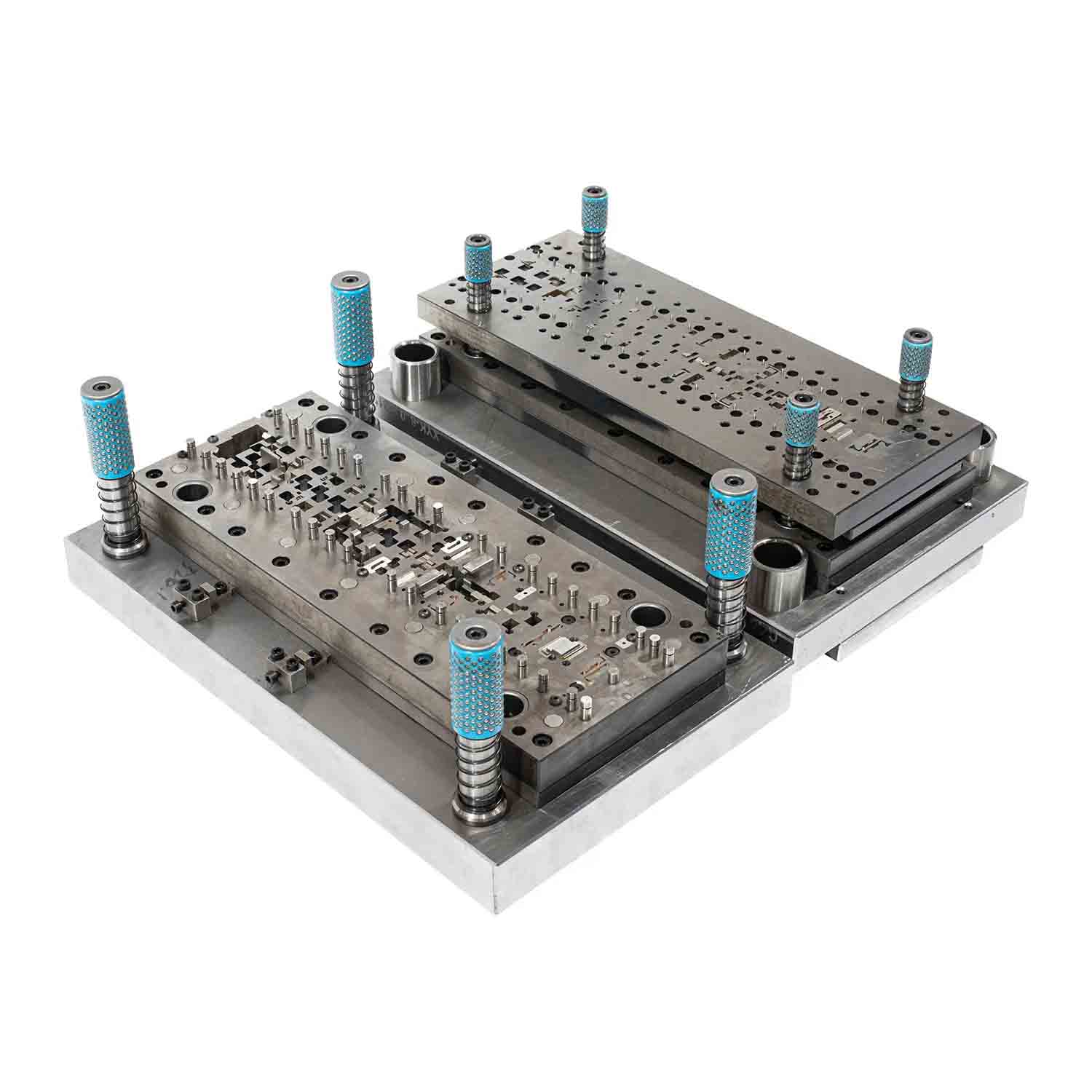

Xiamen Hongyu Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.Sensor Components

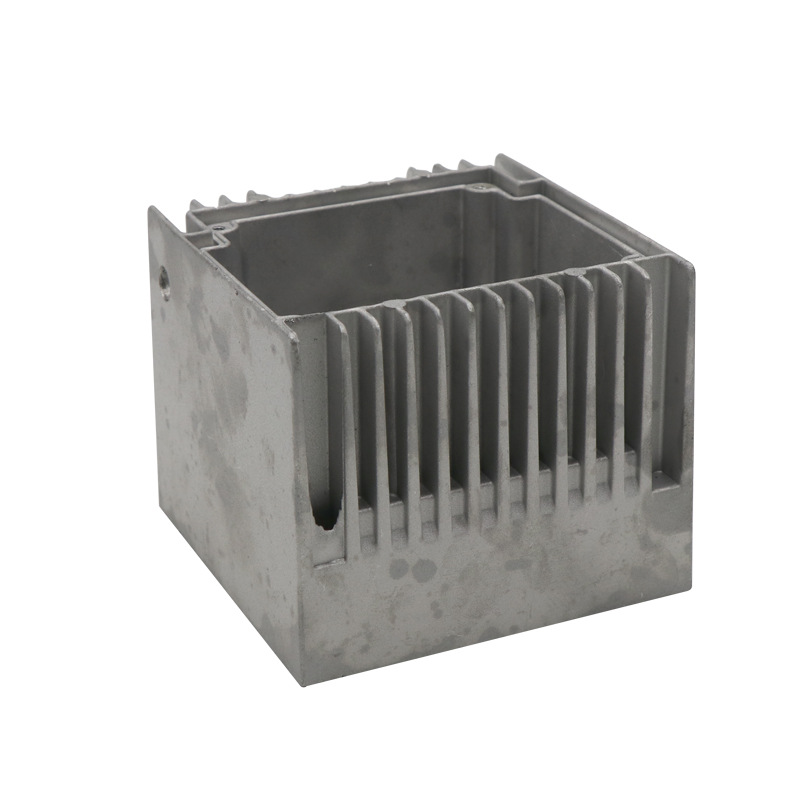

HY is a manufacturer and seller of sensor components. HY's appliance accessory sensor components are available in a variety of materials, including deep-drawn aluminum, copper, mild and high carbon steel, and various stainless steels.