- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

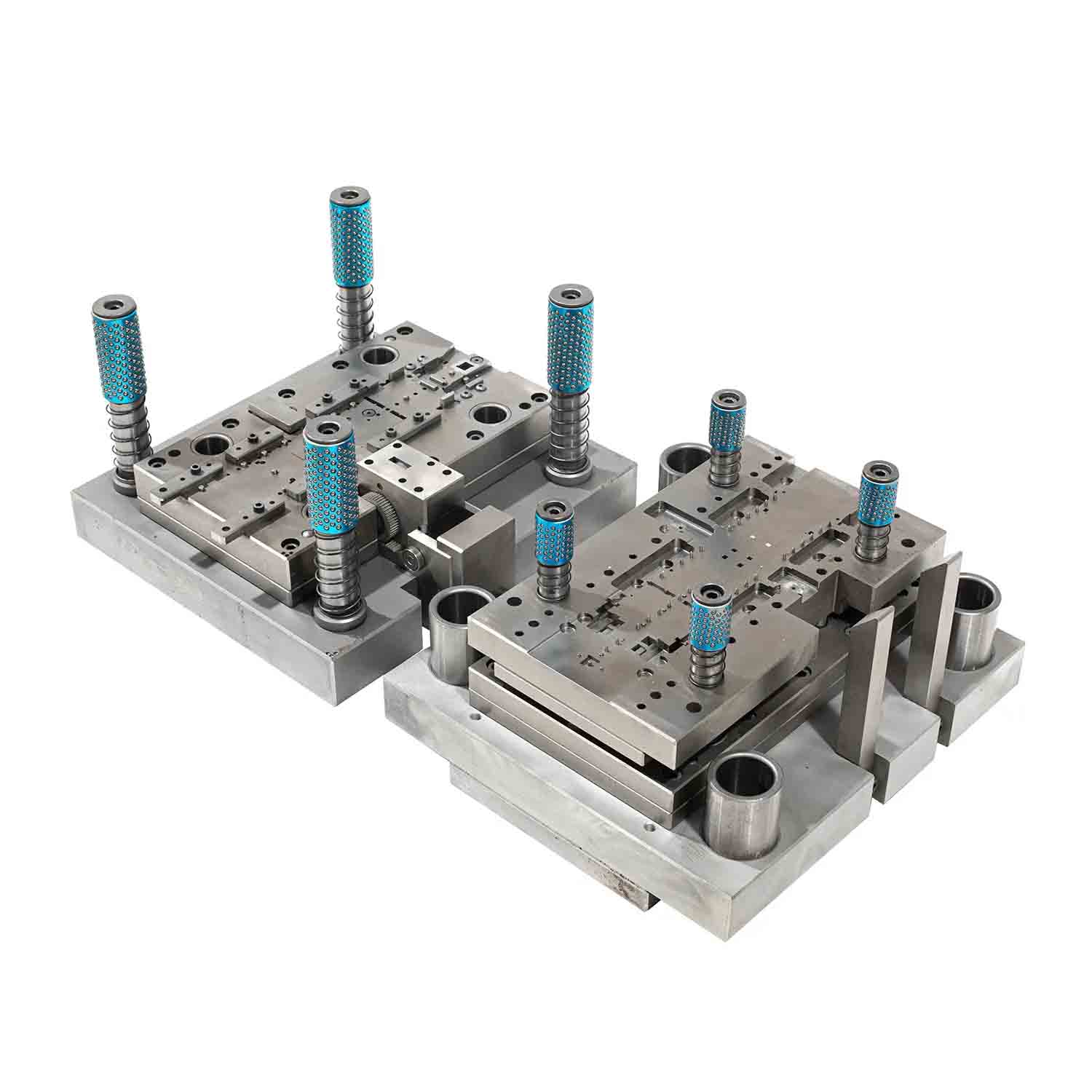

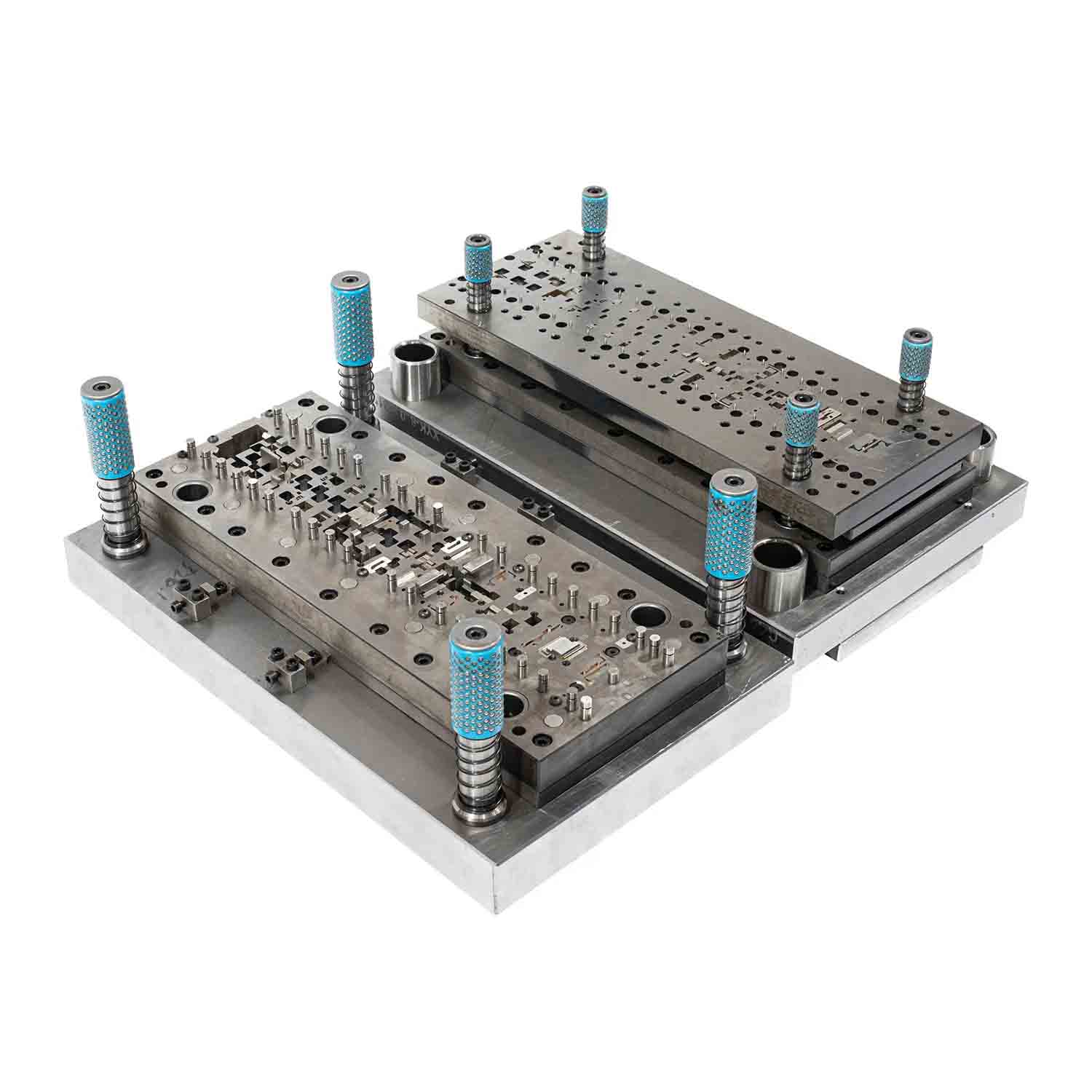

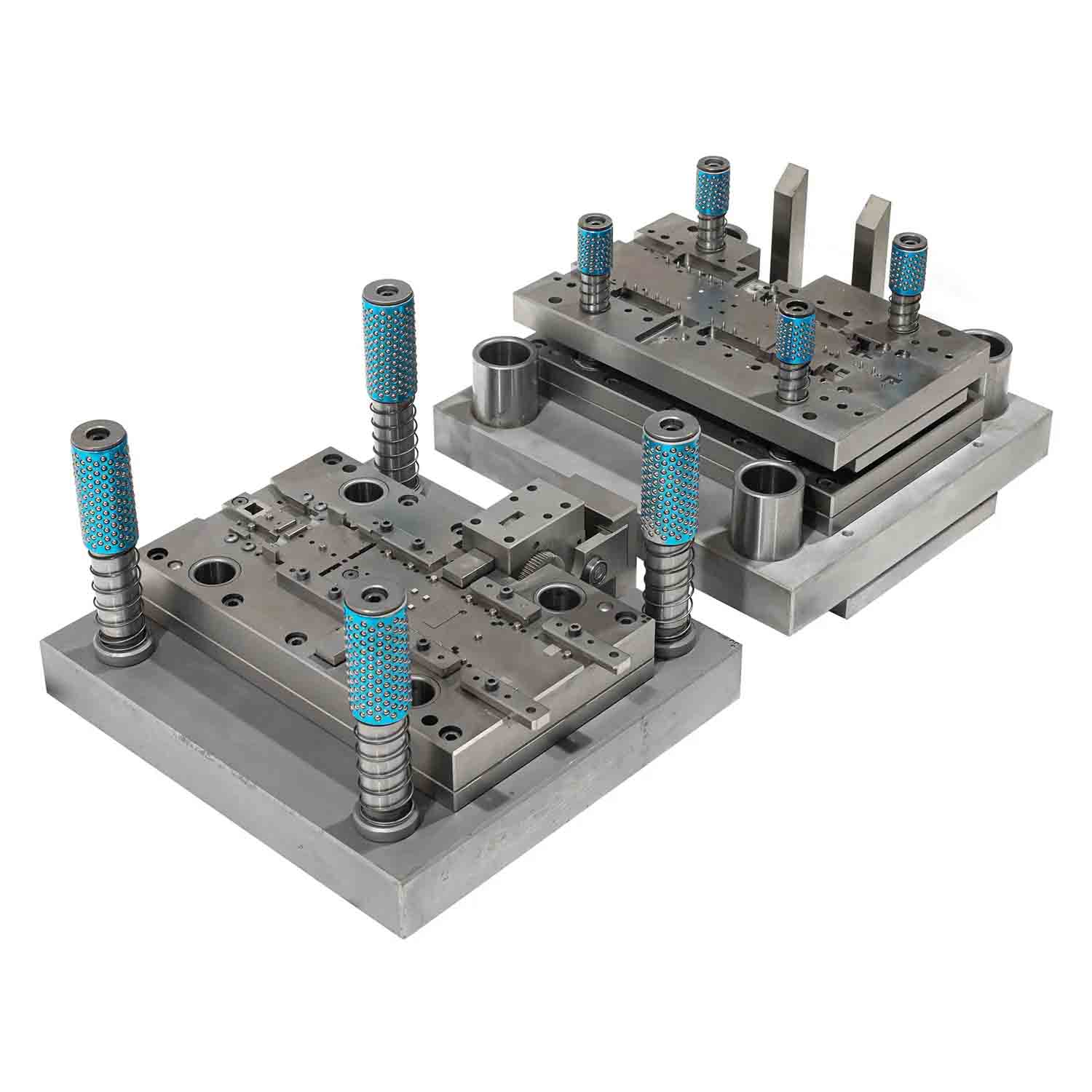

Custom Metal Stamping Dies

HY Custom Metal Stamping Dies are used in the automotive, medical and aerospace industries, focusing on precision tools that produce high-quality metal parts. Metal stamping dies are usually made of steel or carbide, a strong and durable material, and HY can custom design them to meet each customer's specific needs.

Send Inquiry

Custom Metal Stamping Dies provide customized services to various industries to create high-quality metal stamping parts. Because the stamping parts produced by stamping molds have consistent dimensional accuracy, fast speed and good quality, they are an ideal choice for mass manufacturing. HY can be customized according to customers' specific requirements, including size, shape and accuracy requirements of parts. With the ability to mass-produce complex parts, we produce satisfying products flawlessly. Customized metal stamping molds have become one of the important tools in modern manufacturing. If you want to customize complex machinery, small brackets or clamps, choosing HY will make you satisfied.

One of the main advantages of custom metal stamping dies is their versatility. They can be used to make a variety of parts, from simple terminals to complex assemblies used in aerospace, medical and automotive applications. Versatility in that it can be customized to meet the specific needs of a project. HY communicates closely with customers to ensure that every step in the production process meets standards.

Another advantage of custom metal stamping molds is the ability to produce parts quickly and efficiently. Mass production of parts often requires a high degree of precision, and custom production provides a way to produce parts faster and with higher precision, reducing the time and resources required to produce complex parts.

Finally, custom metal stamping molds can help reduce waste and increase efficiency in the manufacturing process. Traditional methods often result in significant waste, inefficiencies and high costs. HY is designed to minimize waste by accurately forming parts with minimal scrap, resulting in a more efficient and cost-effective production process.