- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

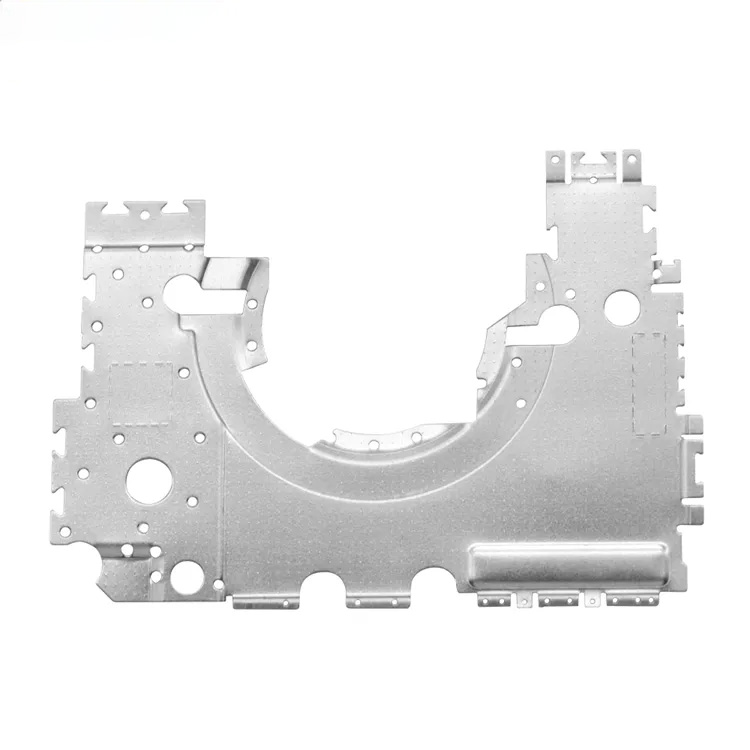

Drive Shaft Assembly

Xiamen Hongyu Intelligent Technology Co., Ltd. integrates R&D, production, sales and after-sales service. Its main products include automobile drive shaft assembly (commonly known as: drive shaft), automobile constant velocity joint (commonly known as: cv joint), cv joint dust cover repair kit. In order to provide more convenient and faster service, we always reserve a large number of hot-selling models at home and abroad.

Product Name: Stamping Drive Shaft Assembly

Origin: Fujian, China

Application: Drive Shaft Connecting Parts

Special: Welcome To Customize OEM/ODM

Certificate: IATF16949, ISO14001, SGS RoHS

Send Inquiry

|

Size |

OE standard |

|

Applicable models |

Toyota, Honda, Mazda, Kia, Hyundai, Ford, Volvo, Tesla, Volkswagen, Mercedes-Benz, BMW, etc. |

|

Processing technology |

Die casting, finishing |

|

Surface treatment |

Frosting, spraying |

|

Heat treatment process |

Carburizing |

|

Scope of use |

Widely used in automobile, home appliances, aerospace, defense, construction and other industries |

Product Introduction

HY's drive shaft assy is integrally formed by casting process, made of forged steel, with strong corrosion resistance and high toughness, and high-density rubber, explosion-proof cracking and enhanced durability.

Carburizing heat treatment process improves the mechanical properties of the bell cover and the overall ball cage, and multiple grinding processes reduce the wear of the ball on the ballway, improve the service life and enhance wear resistance.

All drive shaft assembly parts have undergone rigoros durability tests to ensure the function and life of the components;

The overall casting process is adopted, and the drive shaft part has large torque and impact resistance;

Standard spline processing, strictly in accordance with OE parameters, direct replacement and installation, no need to adjust the fit and matching;

High-precision machining, concentricity tolerance range is less than 0.05mm;

Smooth and durable, can maintain high-speed operation between 200°-500°, acid and alkali corrosion resistance;

The torsion angle exceeds 22° of the T-type inner cage, solves the noise problem, and shows good performance;

Dust cover design, acid and alkali resistance, tensile resistance, and tear resistance.

HY can customize various specifications of transmission shaft assemblies according to customer requirements, and can also customize transmission shaft assemblies according to drawings or samples.