- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

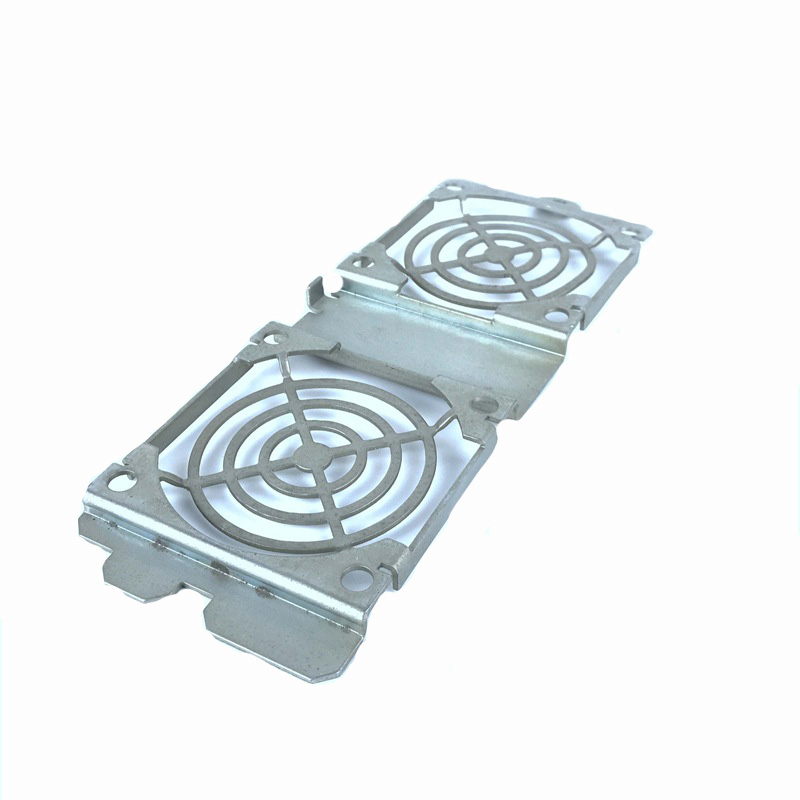

Pc Fan Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is an ISO enterprise specializing in the manufacture of hardware accessories. It has more than 17 years of processing experience. Including pc fan bracket, sheet metal CNC processing, shell, bracket, chassis design, and the production and manufacturing of internal functional parts of products. High quality, on-time delivery, professional design, and one-stop service are the reasons for our long-term cooperation with well-known customers such as HAN's LASER, Formlabs, Samurai, Baxter, VELKASE, etc. As long as you give us the function, performance, and even creativity of the product, we can turn the product from creativity into reality. Welcome to consult immediately.

Item: computer case fan bracket

Certificate: ISO9001:2008

Customization: Support customized OEM service

Send Inquiry

Basic process of cold stamping of computer case fan bracket

According to the deformation characteristics of the material, the cold stamping process atmosphere can be divided into two categories: separation process and deformation process.

1. Separation process: refers to the process after the stamping process is completed, the stress of the deformed part of the material exceeds the material's breaking stress, causing the material to break and separate. For example, punching, blanking, trimming and other processes.

2. Deformation process: refers to the process after the stamping process is completed, the stress of the deformed part of the material exceeds the value of the material's yield stress σs but does not reach the value of the breaking stress σb, thereby causing the material to undergo plastic deformation and change the original shape and size of the material. For example, bending, drawing, flanging, bulging and other processes.

|

Materials |

Carbon steel, stainless steel, galvanized copper, aluminum, brass and other non-ferrous alloy materials |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder coating, electronic spraying, dip coating, mirror polishing, etc. |

|

Tolerance |

±0.002 to ±0.005mm |

|

Surface roughness |

Minimum Ra0.1 to 3.2 |

|

Drawing support types |

Stp, Step, Igs, Xt, AutoCAD (DXF, DWG), PDF or sample |

|

Items |

Stamping computer fan bracket |

These common cold stamping processes are almost all used in our pc fan mount. For example:

1> Punching-VC material, VC semi-finished product, Fin, Clip, gasket, Base, etc.

2> Drawing-VC material

3> Bending-FIN, Clip, Frame

4> Flanging-FIN

5> Bulging-VC rivet

6> Extrusion-VC rivet, heat pipe pressing

7> Shrinking-heat pipe (shrinking of hard pipe is actually cold extrusion)

8> Correction-VC, heat pipe, etc.

As a processing and supply factory for Pc Fan Bracket, HY has rich processing experience and a systematic processing department for the forming principles, design requirements, dimensional accuracy, etc. of various stamping processes.

For example, when designing the deep drawing cavity of VC convex plate, what is the minimum R angle that can be achieved? How to avoid cracks in the R angle at high temperature due to stress or local thinning? For example, the mold design and feed parameters of heat pipe shrink hard pipe and shrink hose, etc.

A simple cpu fan bracket involves professional stamping technology, mold technology, and metal material forming technology. HY has a professional mold design team and processing personnel who can design solutions according to the customer's ideas.

For cpu fan mounting bracket components, there are generally two types of molds: single punching die or continuous die. HY can basically determine what mold to use based on production capacity, benefits, product complexity and other aspects.

1. If it takes multiple processes to stamp out all the features, a continuous die should be used, otherwise several sets of molds should be opened and divided into processes.

For example: punching first, then deep drawing, and then trimming and blanking; if a continuous die is used, it is directly divided into three stamping stations on a set of continuous dies to complete in sequence, which greatly saves stamping hours and manpower handling, loading and unloading time.

2. For mass production, continuous molds can be considered.

For the same reason, although a single punching die is cheap, the production capacity may not keep up, and finally several sets of copy molds have to be opened, which does not save costs, but increases manpower investment.

3. For mass production, but there is no production capacity pressure and the total demand is not large, consider a single punching die. It can reduce the investment cost of the mold.

If the quantity is particularly small, a simple mold can also be used flexibly.

HY can choose different scenarios, different molds, and corresponding cold stamping equipment according to customer needs. According to the actual situation of the equipment, the appropriate process/process can be selected.

Factory non-standard custom precision hardware stamping metal copper computer case fan bracket.

HY invites you to visit our factory to purchase the newest and high-quality Pc Fan Bracket. We are looking forward to working with you