- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Electronic Metal

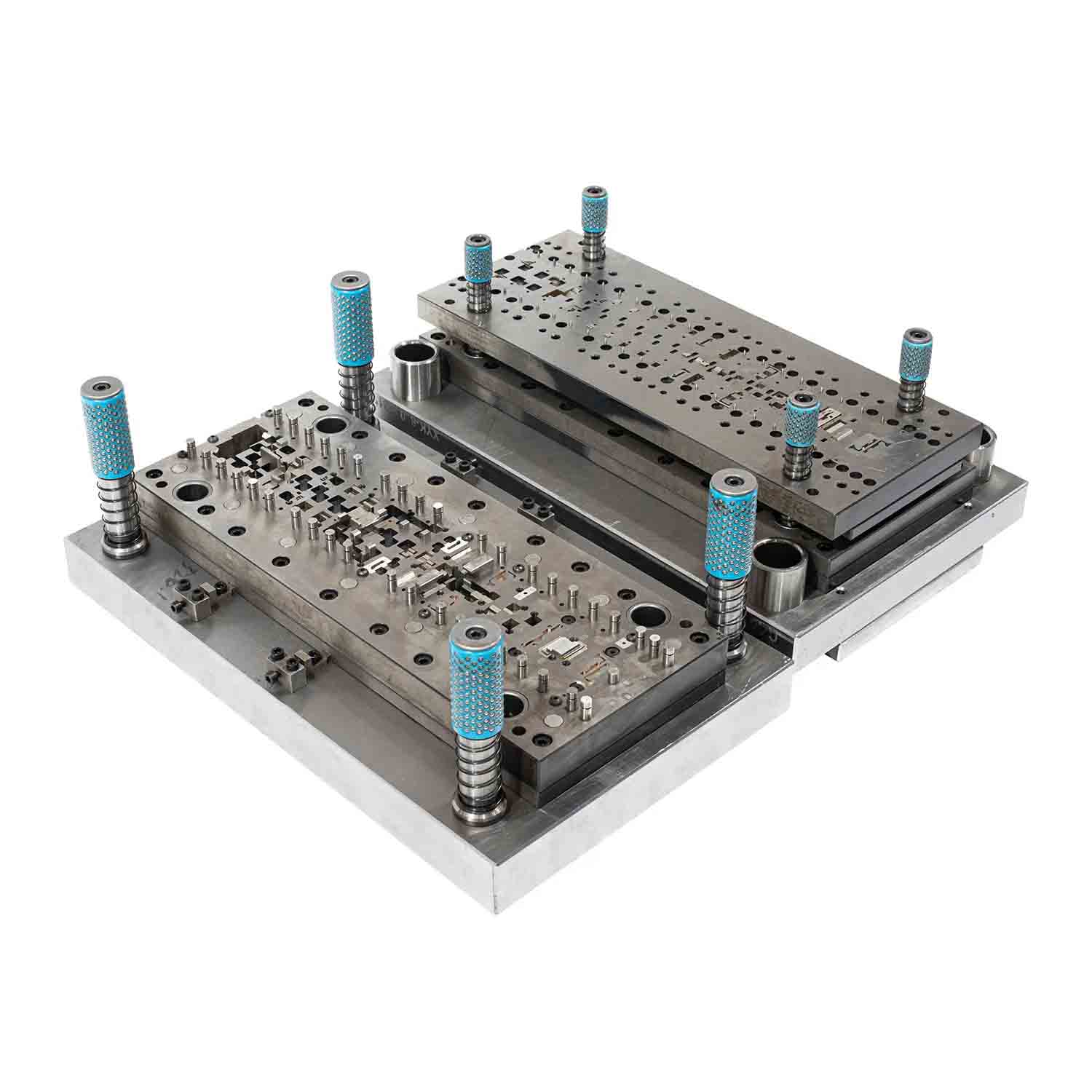

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in aluminum alloy and zinc alloy die-casting processing, and has 17 years of relevant processing experience. HY supports diversified comprehensive services from mold design, manufacturing, and production.

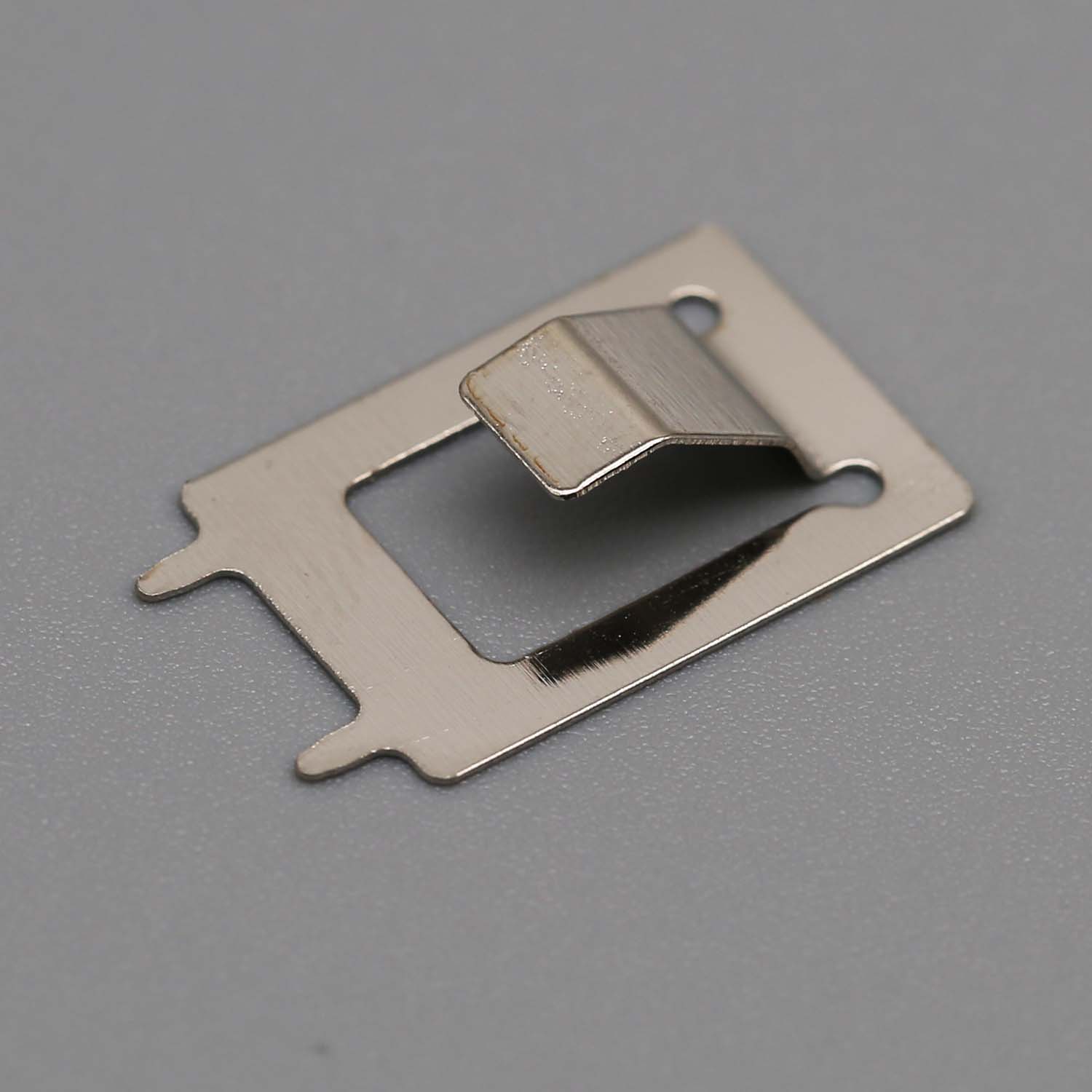

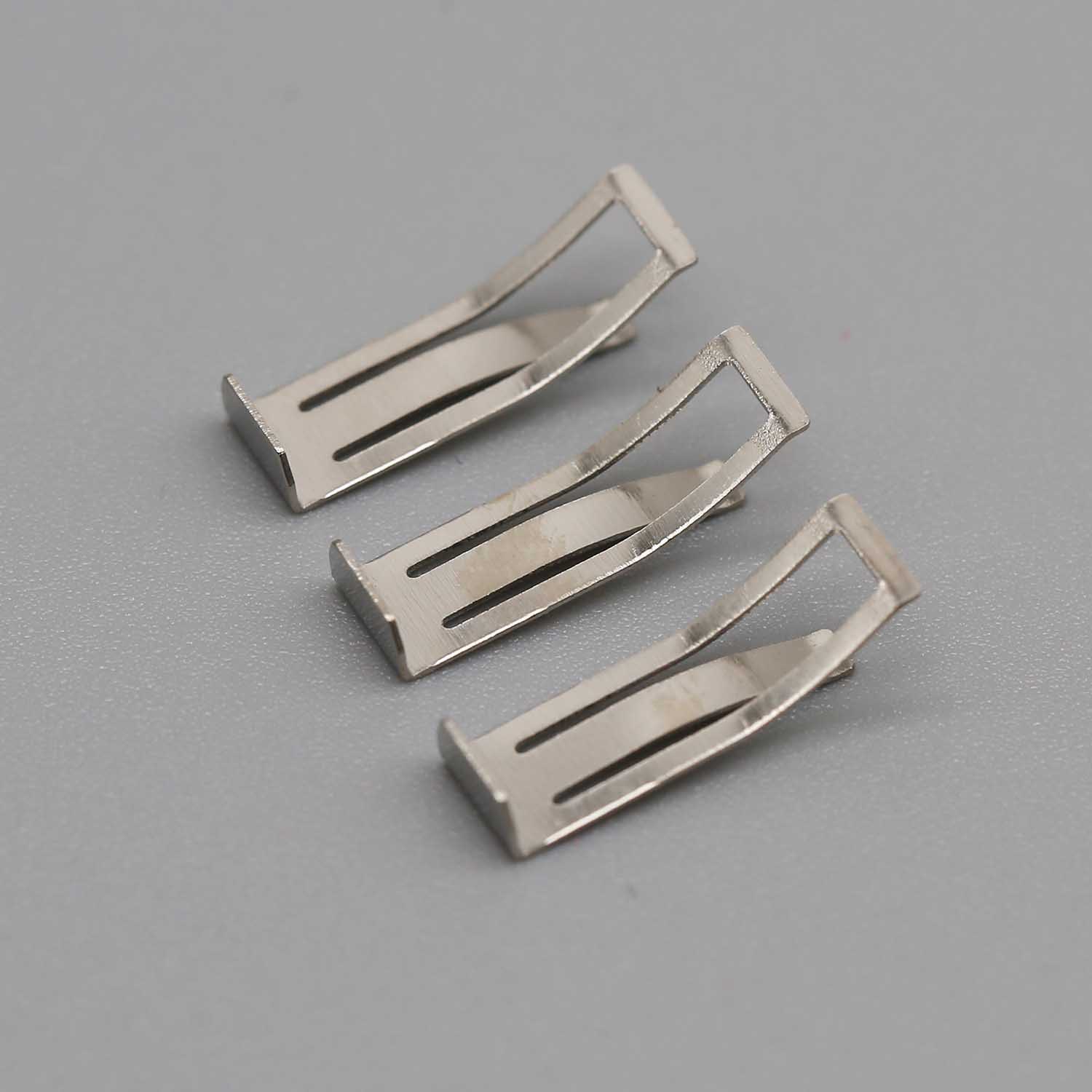

Processing service: Stamping electronic metal accessories

Customization service: Support customization, and can design solutions according to customer needs

Processing type: Metal forming

Tolerance requirement: ±0.02mm

Send Inquiry

Stamping electronic metal accessories are usually small in size, but they are key products for the operation of systems in the automotive, energy, aerospace and other fields.

These precision metal stampings are small in size and are produced in the same way as other commonly sized stampings, in high-speed presses, slide forming machines and a series of other cylindrical equipment.

|

Product model |

metal electronic |

|

Material |

Aluminum alloy, zinc alloy, copper, brass, special materials support customization |

|

Surface treatment |

Coating, anti-rust oil, anodizing, natural, customized according to customer needs |

|

Processing type |

Precision stamping, laser cutting, punching |

|

Quality control |

CMM, caliper, three-coordinate measurement, roughness test, hardness tester, third-party testing |

|

Application areas |

Household appliances, automobiles, construction, industrial equipment, instrumentation, medical equipment, electronic communications |

Whether it is an integrated circuit or other electronic component, there will be heat problems. The heat comes from the energy released by the current passing through the conductor. Because these electronic components need to withstand a lot of heat, they must also absorb heat to maintain the internal temperature of the device or system at a safe operating level.

Therefore, stamping electronic metal accessories must also consider heat dissipation. These small parts will eventually be used for jumper chips, pads, covers, heat sinks, lead frames, or terminals; in addition, precision metal stamping components can also be used as substrates, special-shaped parts or battery shells for some key electronic or microelectronic packages and systems.

As a professional metal pressing company, HY has a professional team of engineers who can recommend any high-performance alloy according to the specific needs of customers. For different application scenarios of customers, such as in semiconductors or other similar devices, if customers want to order specific pure metals, special rare metals such as gold, tin, silver, nickel, copper, tungsten and molybdenum are available.

With strict grasp of precision and strict processing capabilities, our professional engineering team has rich processing experience.

For example, rectangular and round precision stamping parts can usually produce at least 0.127mm to 25.4mm +/-0.01mm diameter 12.7um to 76.2um +/-2.54um.

In 17 years of continuous efforts, HY has become a leader in the stamping electronic metal industry. It has a group of experienced technical teams, which has greatly improved the company's reputation and credibility in the industry. It continues to attract and train outstanding talents. employees, produced a batch of satisfactory products, and the quality has reached industry standards.

The shipping method is mainly through express delivery and logistics. The company aims to use this as a backup to create a more complete after-sales service system, with the purpose of providing customers with a more convenient shopping experience. The materials are all of high quality, ensuring consistent product performance.