- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

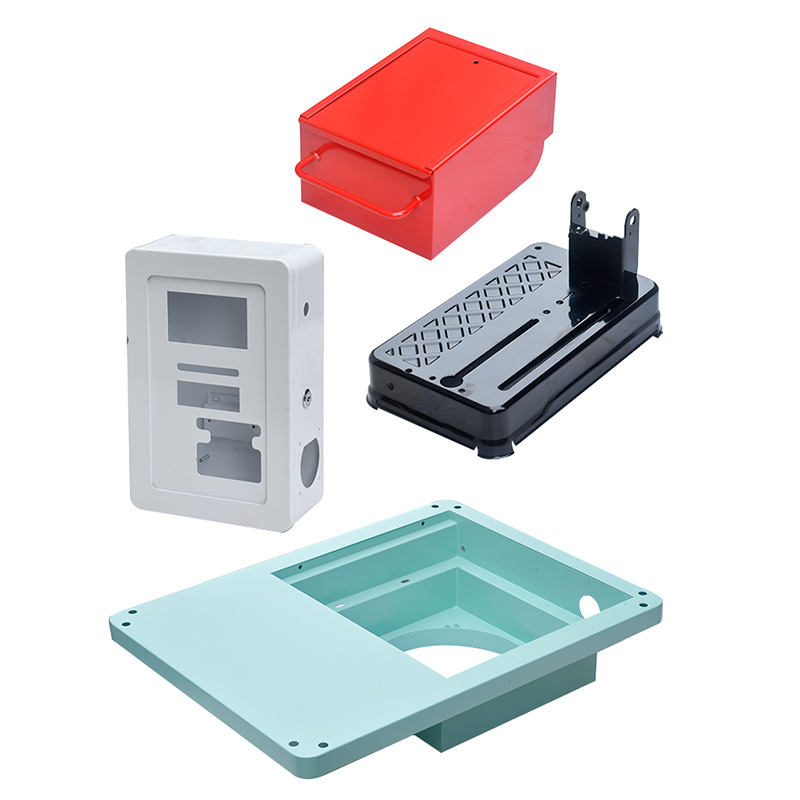

China Stamping electronic metal accessories Manufacturers, Suppliers, Factory

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Stamping electronic metal accessories,black metal electronic,metal electronic,Shrapnel,Stainless steel shrapnel, We've been willing to provide you with the lowest selling price during the market place, greatest high quality and quite nice sales service.Welcome to do bussines with us,let's be double win.

Stamping electronic metal accessories, With the support of our highly experienced professionals, we manufacture and supply best quality items. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the require of customers to meet the requirement of customers.

Hot Products

battery trays

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customizedTransmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.scalpel blades

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional and reputable integrated manufacturing and trading company with many years of experience in various medical and laboratory fields. HY has established extensive and stable cooperative relations with many customers at home and abroad, with footprints in Europe, the United States, the Middle East and Russia, and can provide you with one-stop medical and laboratory product services.

Type: scalpel blades

Features: removable and replaceable, complete specifications

Material: carbon steel, stainless steelStamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing partsCar Rims

Xiamen Hongyu Intelligent Technology Co., Ltd. is a comprehensive enterprise integrating design, R&D, manufacturing, sales and after-sales service. The main products include original wheels, modified wheels, car rims, off-road wheels, racing wheels, etc. The wheels are available in multiple specifications and sizes from 13 inches to 26 inches, supporting personalized forging and customization by customers.

Wheel structure: integral

Wheel diameter: 13 inches, 18 inches, support customization

Material: aluminum alloy

Applicable models: Tank 300, Wrangler, Great Wall, Tesla, BMWCamera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.