- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China single cup drip coffee maker Manufacturers, Suppliers, Factory

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of single cup drip coffee maker,small drip coffee maker,large filter coffee machine,Zinc alloy die-cast coffee machine accessories,Die cast coffee machine filter accessoriesn, We, with great passion and faithfulness, are prepared to present you with best companies and striding forward along with you to create a dazzling upcoming.

single cup drip coffee maker, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We have been looking for the wholesale, Drop ship. Please contact us if you are interesting our items. Hope to do business with you all. High quality and fast shipment!

Hot Products

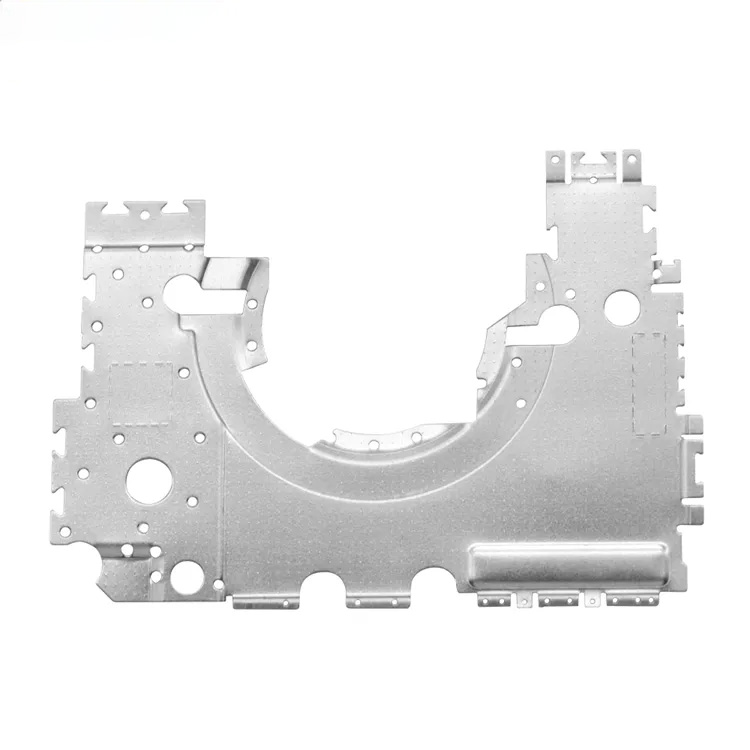

Casting Clutch Components

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of Casting Clutch Components, covering an area of 12,000 square meters, equipped with machining centers, gantry CNC lathes, laser cutting machines, CNC bending machines and other equipment. The company has more than 70 skilled engineers and professionals. Products are exported to more than 30 countries including the United States, Mexico, Spain, Norway, Morocco and South Korea.

Product Type: Casting Clutch Components

Size: Customization supported

Quality Control: 100% full inspection

Certification: ISO9001/CE/ROHS, IATFexpansion bolts

Xiamen Hongyu Intelligent Technology Co., Ltd., with many years of export experience, our products are sold well in Europe, the United States, the Middle East and Southeast Asia. The expansion bolts manufactured by HY fully comply with international standards and are well received by domestic and foreign customers. HY's products cover automotive fasteners, mechanical fasteners, construction fasteners, power fasteners, railway fasteners, household appliance fasteners and chemical fasteners. The product standards include DIN, ISO, GB and ASME/ANSI. HY's products serve all over the world. We hope to continue to strengthen cooperation and grow together.

Stainless steel: SS201, SS303, SS304, SS316, SS316L, SS904L, SS31803

Surface treatment: zinc (yellow, white, blue, black), hot dip galvanizing (HDG), black, Geomet, Dacroment, anodizing, nickel plating, zinc nickel plating

Size: M5-M42

Processing technology: stamping cold headingPc Fan Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is an ISO enterprise specializing in the manufacture of hardware accessories. It has more than 17 years of processing experience. Including pc fan bracket, sheet metal CNC processing, shell, bracket, chassis design, and the production and manufacturing of internal functional parts of products. High quality, on-time delivery, professional design, and one-stop service are the reasons for our long-term cooperation with well-known customers such as HAN's LASER, Formlabs, Samurai, Baxter, VELKASE, etc. As long as you give us the function, performance, and even creativity of the product, we can turn the product from creativity into reality. Welcome to consult immediately.

Item: computer case fan bracket

Certificate: ISO9001:2008

Customization: Support customized OEM serviceDie Casting Mechanical And Electrical Shroud Fan

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2Casting Medical Valve

HY is a medical valve factory from China. Casting Medical Valve is used to change the channel cross-sectional area and medium flow direction. It has functions such as diversion, cut-off, regulation, throttling, check, diversion or overflow pressure relief. Medical valve castings are control components in pipeline fluid delivery systems. Quality Control: 100% QC Inspection

Certification: ISO9001/CE/ROHS

Size: Support OEM/ODM customizationEnergy Vehicle Charging Gun Housing

HY is a manufacturer and supplier of Energy Vehicle Charging Gun Housing. HY precision metal stamping mold new energy vehicle charging gun stamping parts specifications: 1. The material is phosphor bronze C5191. Material thickness is 0.3mm. 2. Support surface treatment: silver plating, gold plating, nickel plating or chrome plating. 3. The seams of the stamped parts are tightly combined, without deformation, overlap, or gaps. In the drop test from a height of 2 meters in any direction, the components were not damaged.