- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China large filter coffee machine Manufacturers, Suppliers, Factory

Our enterprise insists all along the quality policy of "product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, purchaser first" for large filter coffee machine,small drip coffee maker,single cup drip coffee maker,Zinc alloy die-cast coffee machine accessories,Die cast coffee machine filter accessoriesn, Hope we can easily generate a more glorious potential along with you by means of our endeavours within the long run.

large filter coffee machine, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

Hot Products

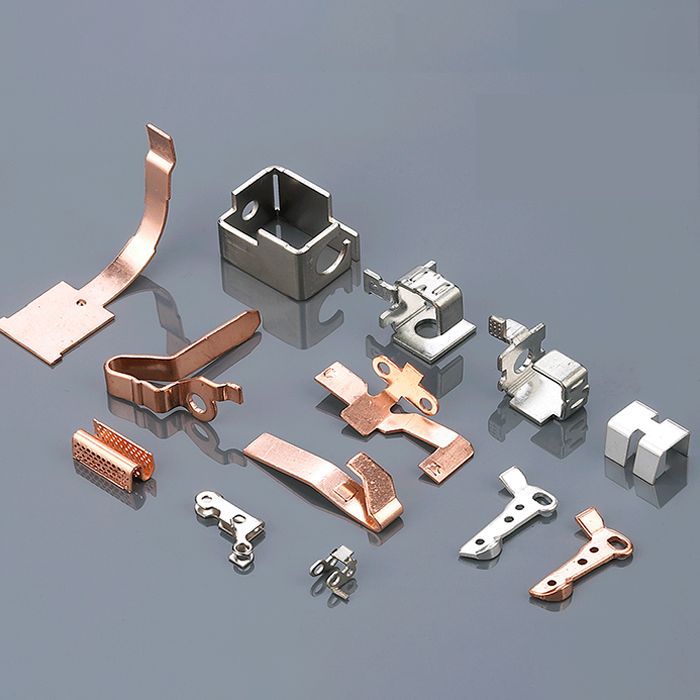

Inconel Part Aerospace Stamping

HY is a factory in the stamping industry. HY is the industry leader in custom inconel part aerospace stamping for use in the electronics, construction, aerospace, defense and medical industries.stainless steel rivets

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of all kinds of stainless steel rivets, blind rivets, rivet nuts, pressure rivets, national standard fasteners, non-standard fasteners, and riveting tools. The company has a complete set of advanced production equipment and automatic lathes, and adopts international advanced standards for production. "Zero defects, create brands" is HY's purpose. We hope to establish a good cooperative relationship with domestic and foreign customers on the basis of equality, mutual benefit and common development.

Surface treatment: natural, black, galvanized, other

Material: stainless steel, aluminum, brass, special alloy

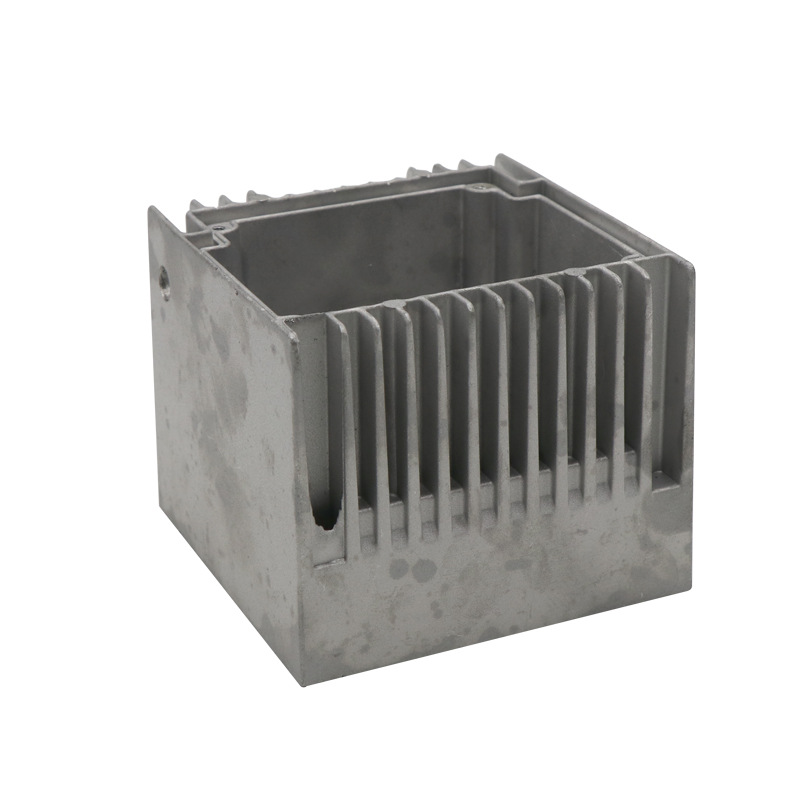

Processing technology: stampingHeat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.solar panel mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that mainly manufactures photovoltaic modules and photovoltaic brackets. It mainly produces high-power 550-730 watt photovoltaic modules and photovoltaic brackets. HY is mainly engaged in the design and production of rooftop and ground solar photovoltaic installation solutions. Related products include stainless steel roof hooks, aluminum alloy roof brackets, aluminum alloy solar panel clamps, steel ground screws, etc.

Product type: solar panel mounting system, solar panel pole mountr

Processing services: stamping, die casting, bending, welding, punching, cutting

Material: aluminum alloy, stainless steel

Service life: 20-25 yearsStainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray PaintingEngine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 days