- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China subframe car Manufacturers, Suppliers, Factory

Gaining client pleasure is our company's aim without end. We are going to make excellent efforts to create new and top-quality goods, meet your special requirements and provide you with pre-sale, on-sale and after-sale companies for subframe car,subframe,rear subframe,front subframe,sub frame, We welcome new and old consumers from all walks of everyday living to speak to us for upcoming business enterprise interactions and mutual accomplishment.

subframe car, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.

Hot Products

Stamping Lighting Components

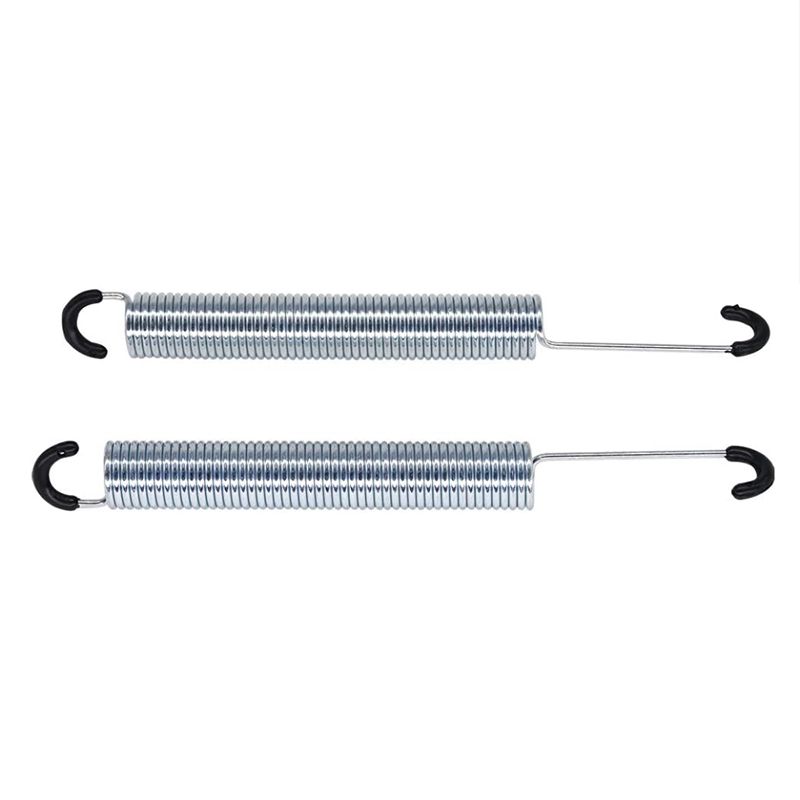

HY is a manufacturer and factory of Stamping Lighting Components.HY has extensive experience in producing metal lighting electrical stamping for the lighting industry that comply with all applicable codes and regulations. stamping lighting components are popular.Stamping Wire Formed Fasteners

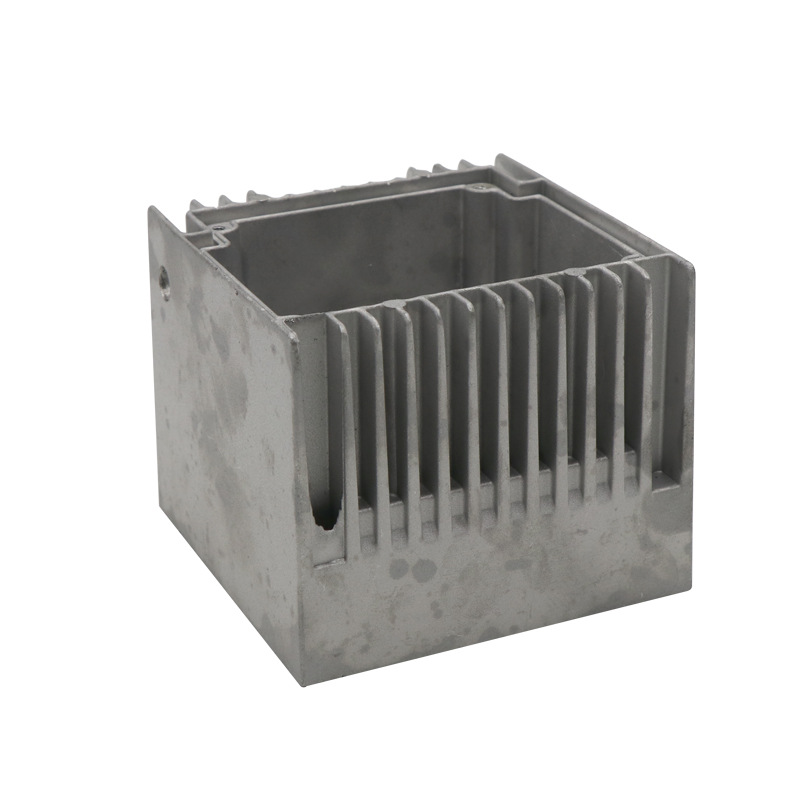

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Die Cast Aluminum Light housing

As one of professional manufacturer, HY would like to provide you high quality Die Cast Aluminum Light housing. And we will offer you the best after-sale service and timely delivery.

Waterproof index: IP66 IP67

Seismic resistance index: IK08 IK09 IK10

Material: Aluminum + PC

Die-cast aluminum light housing working temperature (℃): -40-60

Certification EMC, RoHS, CE, FCC, LVD, 3G Vibration, ISO 9001, ISO 14001Stainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray PaintingMeat Grinder Screw

As a leading manufacturer of meat grinder die-casting parts, HY specializes in the production of high-quality meat grinder screws. HY's screws provide precision and efficiency while ensuring perfect grinding every time. Our meat grinder screws are made of high-quality materials, making them durable and reliable even in the most demanding conditions.Paint Spoon

Product name: Hardware stamping paint spoon

Material: carbon steel plate

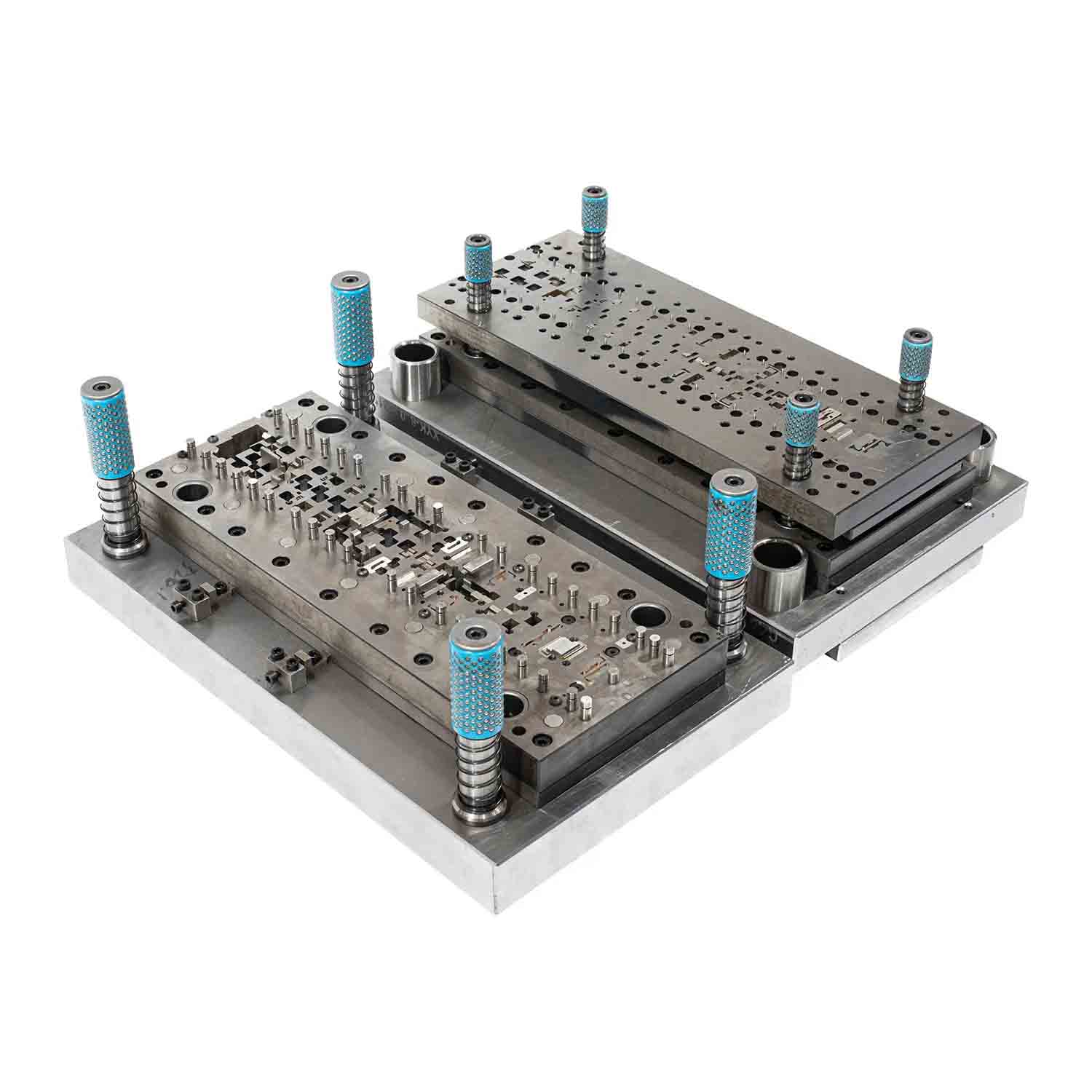

Mold: multi-process continuous mold

Processing size: 66.3*34*10 (mm)

Process: cutting, forming, deep drawing, cold extrusion