- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

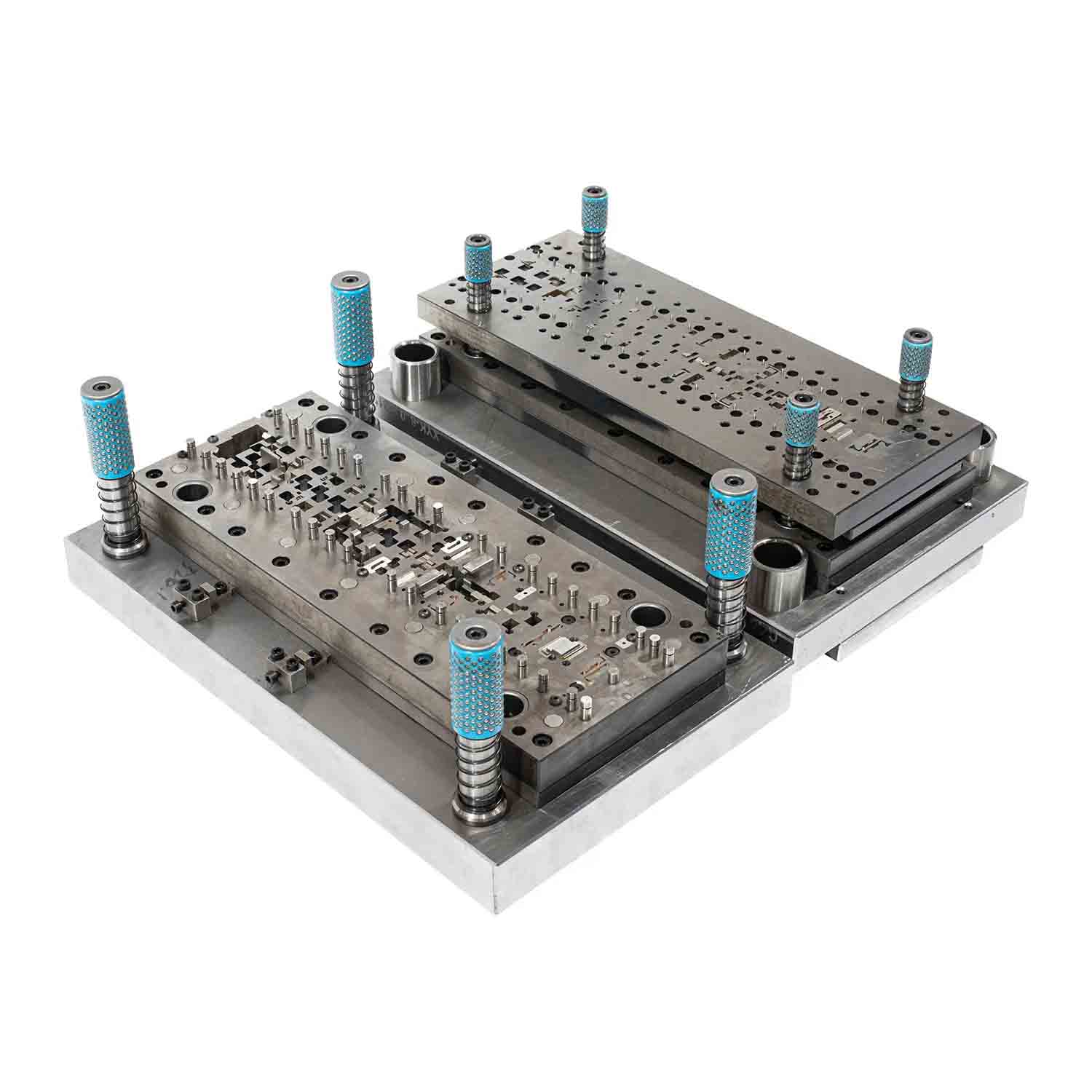

China Progressive Stamping Manufacturers, Suppliers, Factory

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for Progressive Stamping,Progressive Die Stamping,Metal Stamping Dies, We are wanting forward to even larger cooperation with abroad customers dependant on mutual rewards. Make sure you sense free to make contact with us for more depth!

Progressive Stamping, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products and solutions. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best in your case always.

Hot Products

stainless steel rivets

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of all kinds of stainless steel rivets, blind rivets, rivet nuts, pressure rivets, national standard fasteners, non-standard fasteners, and riveting tools. The company has a complete set of advanced production equipment and automatic lathes, and adopts international advanced standards for production. "Zero defects, create brands" is HY's purpose. We hope to establish a good cooperative relationship with domestic and foreign customers on the basis of equality, mutual benefit and common development.

Surface treatment: natural, black, galvanized, other

Material: stainless steel, aluminum, brass, special alloy

Processing technology: stampingDie Casting Pump Body

Hongyu is a factory specializing in the production of die casting pumps. A pump is a mechanical device that moves fluid (liquid or gas, slurry). Die casting pump body is the process of designing and casting pump parts from aluminum alloy. It can provide products with higher strength and corrosion resistance and handle liquid substances.Car Table

The Car Table produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is designed to provide users with a comfortable space so that they can work or eat on the go. The Car Table produced by HY adopts a fully suspended structure to free up more space and can be adjusted in height to suit a variety of postures.

Color: black, gray, other colors can be customized

Material: polypropylene, ABS

Type: car folding table

Cleaning: washable

Customization: support design customizationGas Stove Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of anti tip bracket for stove. You can order anti tip bracket for gas stove bracket from HY with confidence. We will provide you with the best after-sales service and timely delivery.

Product name: anti tip device for gas stove

Surface treatment: sandblasting anti-slip

Material: aluminum alloy, cast iron, stainless steel, customizable

Advantages: prevent high temperature oxidation and no rust, non-slip and durable, no deformation at high temperatureportable handicap ramp

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional aluminum alloy manufacturer. The company has its own independent technical research and development capabilities, perfect manufacturing processes and sound quality control systems. It specializes in providing portable handicap ramp for residential and commercial places, and provides customized barrier-free solutions for people with limited mobility. It covers an area of 4,500 square meters and supplies more than 15 tons of raw materials per month. HY has obtained a number of Chinese utility model patents, appearance patents, EU appearance patents, CE safety certification, ISO9001:2015 and ISO13485 certificates.

Our main products are divided into two categories:

1. Barrier-free medical rehabilitation aids: crutches, bathing chairs, commode chairs, walkers, etc.

2. Aluminum alloy barrier-free ramps: folding ramps, rolling circular ramps, portable disabled ramps, etc.Die Casting Lower Cover

HY is a manufacturer and supplier of cast lower covers, using presses from 25 tons to 400 tons, and can meet customer needs whether it is precision or large Die Casting Lower Cover.