- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

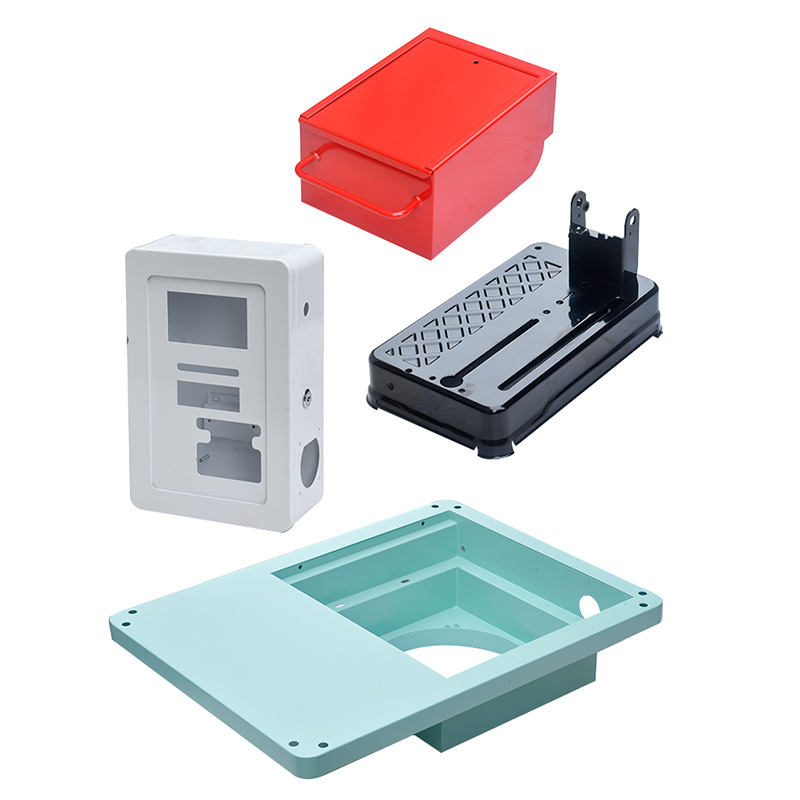

China Progressive Stamping Die Stamping Bracket Manufacturers, Suppliers, Factory

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Progressive Stamping Die Stamping Bracket,Stainless Steel Stamping Bracket,Nickel Alloy Stamping Bracket,Precision Metal Stamping Bracket, Welcome your enquiry, most effective service will likely be provided with full heart.

Progressive Stamping Die Stamping Bracket, We've got 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

Hot Products

Stainless steel flat washer

HY developed metal stamped stainless steel flat washers for customers in the medical industry. Made from 17-7 PH stainless steel, this stainless steel gasket has strong corrosion resistance and is not prone to rust, making it ideal for medical use.Car Seat Frame

The die-cast Car Seat Frame produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-quality die-cast product that can provide stable skeleton support for car seats, effectively protect the safety of passengers during driving, and also provide a more comfortable use experience for car seats. In the production process, HY uses the most advanced die-casting technology and selects high-quality raw materials to ensure the quality and performance of each product, making it your safe and comfortable seat choice.

Type: Car Seat Frame

Material: Cast iron, steel, special alloys support customization

Application scenarios: SUV/Multi-purpose passenger car/RV/camper/caravan/caravan/car trailerCasting Pulleys

HY is famous for its low price and good quality in the stamping industry. HY Casting Pulleys in almost every possible custom diameter and bore size.Energy Vehicle Charging Gun Housing

HY is a manufacturer and supplier of Energy Vehicle Charging Gun Housing. HY precision metal stamping mold new energy vehicle charging gun stamping parts specifications: 1. The material is phosphor bronze C5191. Material thickness is 0.3mm. 2. Support surface treatment: silver plating, gold plating, nickel plating or chrome plating. 3. The seams of the stamped parts are tightly combined, without deformation, overlap, or gaps. In the drop test from a height of 2 meters in any direction, the components were not damaged.Uv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and texturedstroller frame for car seat

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, etc.

Processing technology: metal die-casting