- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

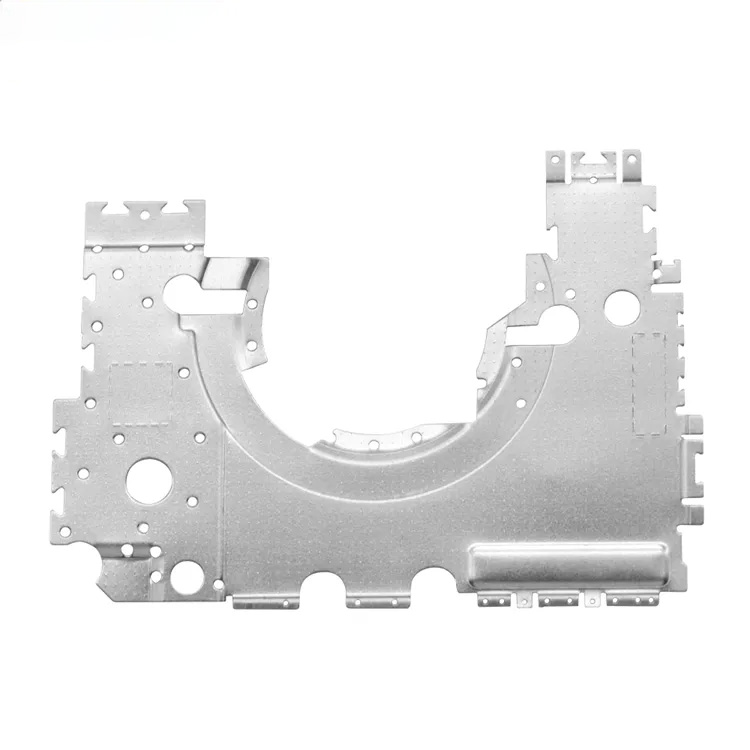

China Progressive Stamping Parts Mobile Phone Manufacturers, Suppliers, Factory

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Progressive Stamping Parts Mobile Phone,Stainless Steel Mobile Phone Stamping Parts,Precision Metal Stamping Parts Mobile Phone,Precision Stamping Die Stainless Steel Mobile Phone Accessories, We welcome you to inquire us by get in touch with or mail and hope to create a successful and cooperative partnership.

Progressive Stamping Parts Mobile Phone, Welcome to visit our company, factory and our showroom where displays various hair merchandise that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Make sure you contact us if you require more information. Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation.

Hot Products

Die Casting Crankcase

Supplier of Die Casting Crankcase from China.The zinc alloy die-cast crankcase houses the motorcycle’s crankshaft and transmission components. What allows us to come up with designs that push the envelope to achieve lighter weight is our casting technology based on in-depth analysis.bmw license plate frame

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in providing customers with local standard license plate frames, such as bmw license plate frame, American standard and European license plate frames, custom car plate frames, with 17 years of processing experience, can provide you with high quality and good service.

Material: metal, stainless steel, aluminum alloy, plastic

Application: auto parts, truck parts

Customized service: support customizationStamping Wrench

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer and supplier specializing in the production of Stamping Wrench. Its main products include measuring tools, mechanical tools, fastening tools, clamping tools, etc. Impact wrench is an efficient and durable mechanical tool, widely used in automobile repair, home repair, aerospace and other fields. Its main advantages are easy to use and efficient, coupled with its high durability and reliability.

Material: 45 steel, 40cr, Q235, customizable

Surface treatment: galvanized, blackened, according to customer needs

Color: original metal color, customizable color selectionUv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and texturedscalpel blades

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional and reputable integrated manufacturing and trading company with many years of experience in various medical and laboratory fields. HY has established extensive and stable cooperative relations with many customers at home and abroad, with footprints in Europe, the United States, the Middle East and Russia, and can provide you with one-stop medical and laboratory product services.

Type: scalpel blades

Features: removable and replaceable, complete specifications

Material: carbon steel, stainless steelStainless steel mixing bowl

Product name:Stainless Steel Mixing Bowls, Usage:Kitchen Home Hotel Restaurant, Logo:Customized Logo Acceptable, Production process: metal stamping,