- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

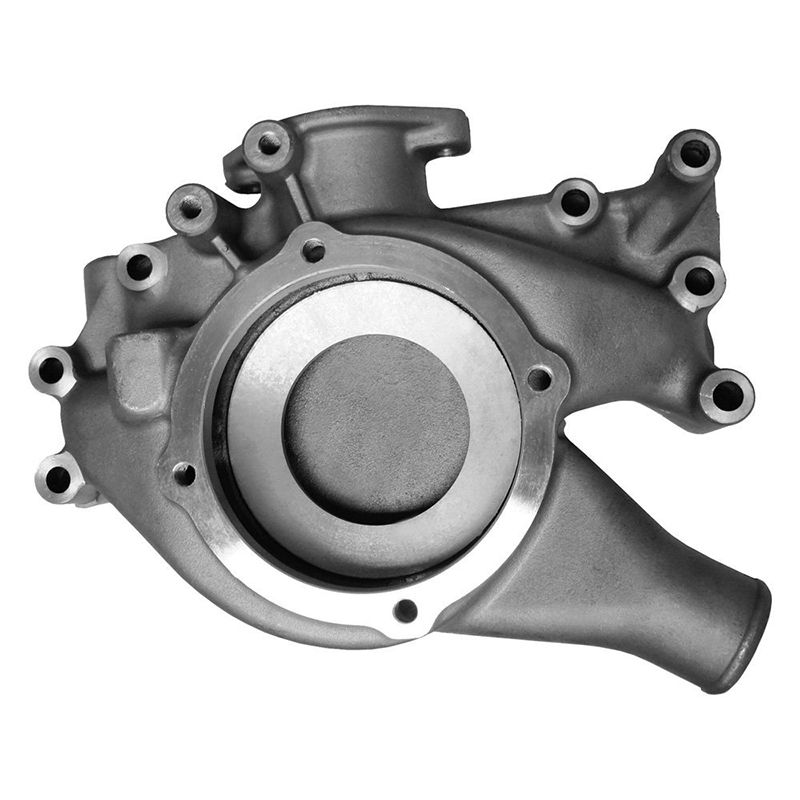

Die Casting Pump Body

Hongyu is a factory specializing in the production of die casting pumps. A pump is a mechanical device that moves fluid (liquid or gas, slurry). Die casting pump body is the process of designing and casting pump parts from aluminum alloy. It can provide products with higher strength and corrosion resistance and handle liquid substances.

Send Inquiry

HY is one of the Die Casting Pump Body manufacturers and experts in China. We can produce any pump casting or cast pump part in our foundry. Most of them are exported to the United States, Canada, France, and Israel markets.

Pump casting production process:

1. Sand mold casting:

If the Die Casting Pump Body is made of iron or cast iron as the raw material. Sand casting would be a better solution. Because sand casting has the advantages of low cost and good intrinsic quality. But compared to investment casting, more machining allowances need to be dealt with.

2. Lost wax casting

When the pump castings are produced using stainless steel investment casting. Lost wax casting would be preferred. Die Casting Pump bodies feature smooth surfaces and tight tolerances. It's like a valve casting. The lost wax process will reduce machining work and result in a uniform net shape casting.

3. Aluminum die castings:

The die-casting process is suitable for thin-wall thickness requirements and special aluminum alloy materials. Such as mounting brackets. Aluminum die castings can achieve high strength and perfect quality. Aluminum die castings are a better choice when you have wall thickness requirements.

HY will adopt quenching and tempering heat treatment process. Improves mechanical properties, hardness, wear resistance and strength.