- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

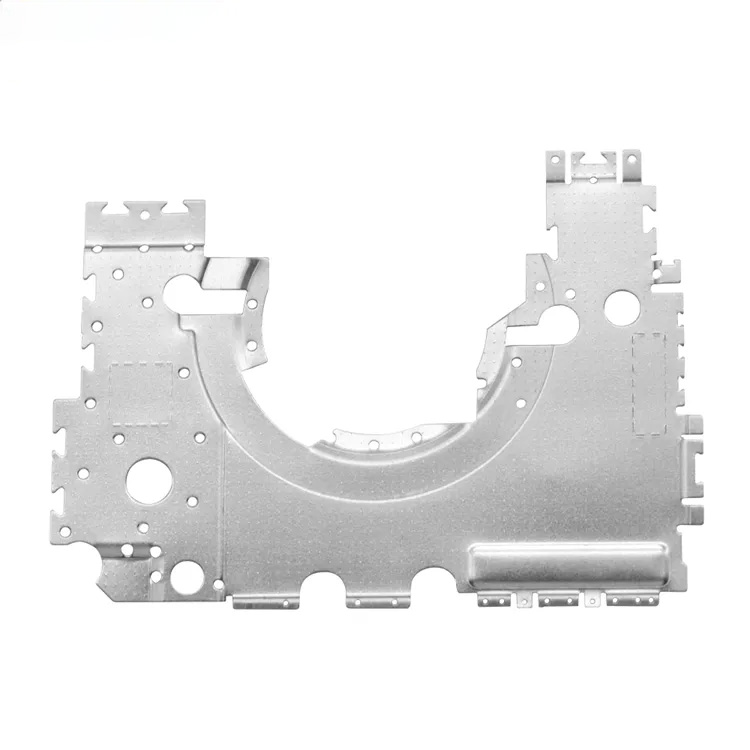

China stamping parts Manufacturers, Suppliers, Factory

Our enterprise insists all along the quality policy of "product high-quality is base of organization survival; customer gratification will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, purchaser first" for stamping parts,stamping small parts,miniature metal stamping,small part metal stamping,deep drawn metal stamping, Hope we can easily generate a more glorious potential along with you by means of our endeavours within the long run.

stamping parts, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of products and solutions and ideas with us!!

Hot Products

Casting Gearbox Components

Hongyu Intelligent specializes in die-casting many important transmission components for the automotive and heavy-duty Casting Gearbox Components Manufacturing stamping industry.Stator And Rotor

Xiamen Hongyu Intelligent Technology Co., Ltd. can provide most products in the motor industry, such as stepper motors, DC brushless motors, servo motors, including stator and rotor, electric push rods and other related accessories. HY can customize products and production lines according to customers' industries, such as medical, industrial control, robots, robotic arms, etc.

Product name: rotor stator

Type: brushless motor

Torque: 0.3Nm

Certification: ISO9001, ISO14001, CE, ROHS, CCC

Customization: support customizationMobile Phone Stainless Steel Stamping Parts

HY sixteen years of industry experience Material: SUS301 Mobile Phone Stainless Steel Stamping Parts specifications: customized according to customer requirements Material characteristics: complies with ROHS, SGS testing Qualification certification: ISO9001 & IATF16949hospital beds

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of medical care equipment. HY produces a wide range of products with a complete import and export qualification system. Its products are exported to Europe, the United States, the Middle East and other regions, including hospital beds, multi-functional nursing beds, electric beds, manual beds, outpatient beds, massage beds, walkers, etc. We welcome customers from all over the world to visit.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: hospital beds

Product use: hospital home furniture nursing beds

Product application scenarios: hospitals, nursing homes, familiesbattery trays

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customizedCar Table

The Car Table produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is designed to provide users with a comfortable space so that they can work or eat on the go. The Car Table produced by HY adopts a fully suspended structure to free up more space and can be adjusted in height to suit a variety of postures.

Color: black, gray, other colors can be customized

Material: polypropylene, ABS

Type: car folding table

Cleaning: washable

Customization: support design customization