- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Precision Metal Stamping Connectors Manufacturers, Suppliers, Factory

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Precision Metal Stamping Connectors,Metal Stamping Connection Parts,Industrial Stamped Connectors,Battery Terminal Connectors,Solar Panel Connectors, We have exported to more than 40 countries and regions, which have gained fantastic popularity from our costumers everywhere in the globe.

Precision Metal Stamping Connectors, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Let us join hands to create a brilliant tomorrow! We're looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to supply you with high quality and efficient services.

Hot Products

Precision Hardware Stamped Aluminum Plate

HY Precision Hardware Stamped Aluminum Plate specifications: 1. The HY precision metal stamped aluminum disc is made of aluminum with a thickness of 0.4mm. 2. This product is used in climate conditioners. 3. The product has high sealing performance and stability.motor mount

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading manufacturing and processing plant with 17 years of processing experience and a mature import and export qualification certification system. We are committed to providing high-standard and high-performance high-quality motor mount auto parts, making us competitive in the global market.

Product type: motor mount

Quality: 100% professional quality inspection

Customization service: support OEM/ODM customizationmedical tweezers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steelbmw license plate frame

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in providing customers with local standard license plate frames, such as bmw license plate frame, American standard and European license plate frames, custom car plate frames, with 17 years of processing experience, can provide you with high quality and good service.

Material: metal, stainless steel, aluminum alloy, plastic

Application: auto parts, truck parts

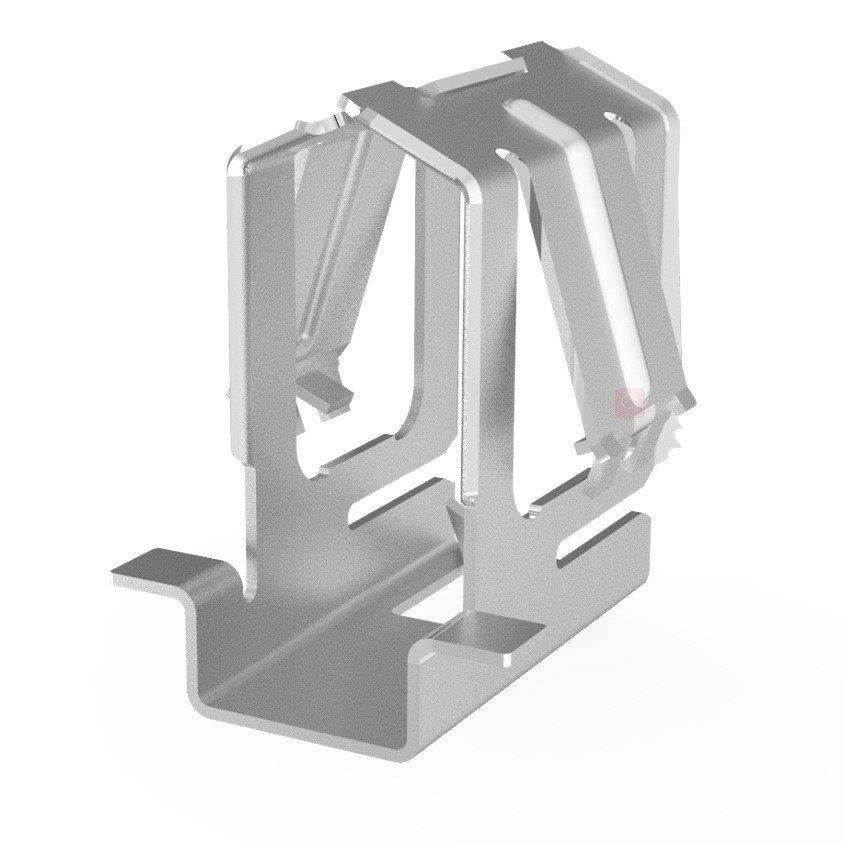

Customized service: support customizationSolar Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is a solar bracket manufacturer integrating scientific research, manufacturing, sales and after-sales service. Solar Bracket is manufactured using metal stamping technology, which is more economical and efficient while ensuring high precision and high quality, ensuring its durability, high strength and stability. Product name: solar panel brackets Color: natural color, black, customizable Service life: 25 years Warranty: 15 yearsStainless steel mixing bowl

Product name:Stainless Steel Mixing Bowls, Usage:Kitchen Home Hotel Restaurant, Logo:Customized Logo Acceptable, Production process: metal stamping,