- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China oil pump Manufacturers, Suppliers, Factory

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for oil pump,engine parts,marine engine parts,parts engine,cylinder head, Adhering on the company principle of mutual gains, we have won superior popularity amid our shoppers because of our excellent products and services, excellent products and aggressive selling prices. We warmly welcome shoppers from home and overseas to cooperate with us for common achievements.

oil pump, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our items or have an OEM order to fulfill, make sure you feel free to contact us now. Working with us will save you money and time.

Hot Products

Engine Turbocharger

Xiamen Hongyu Intelligent Technology Co., Ltd. produces Engine Turbocharger with low price and good quality. It is a well-known domestic die-casting manufacturer. HY has a professional engineering design team and supports customized services. It can design solutions and complete the final product according to the customer's drawings or ideas.

Turbocharger molding process: high pressure casting

Surface treatment: polishing oxidation

Material: aluminum alloy

Tolerance: 0.2

Proofing cycle: 4-7 days

Processing cycle: 8-15 daysStamping Wrench

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer and supplier specializing in the production of Stamping Wrench. Its main products include measuring tools, mechanical tools, fastening tools, clamping tools, etc. Impact wrench is an efficient and durable mechanical tool, widely used in automobile repair, home repair, aerospace and other fields. Its main advantages are easy to use and efficient, coupled with its high durability and reliability.

Material: 45 steel, 40cr, Q235, customizable

Surface treatment: galvanized, blackened, according to customer needs

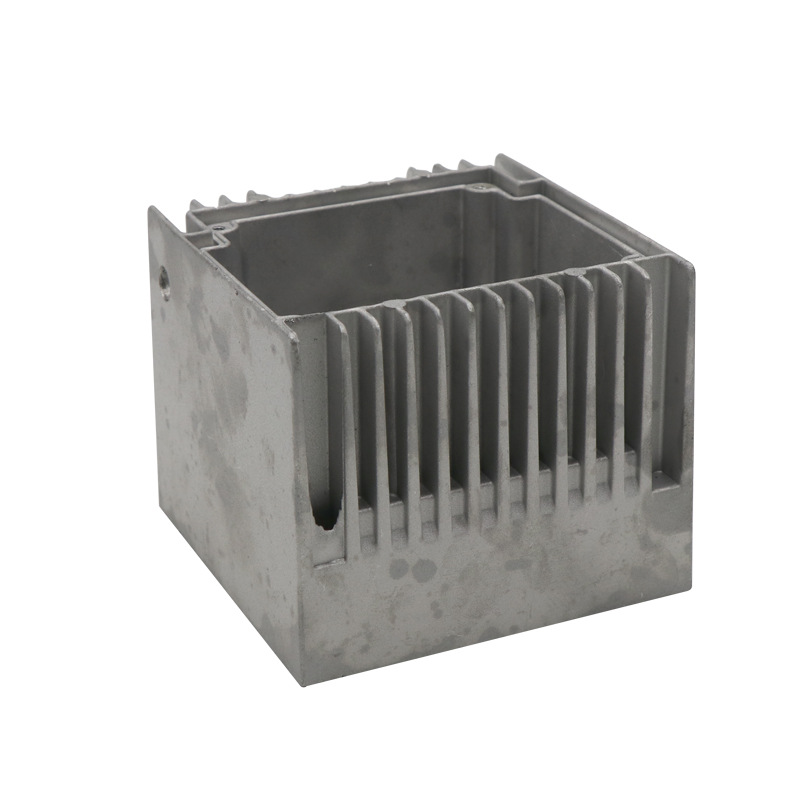

Color: original metal color, customizable color selectionHeat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.Metal Stamping Construction Industry Support

HY is an experienced manufacturer of metal stamping construction industry support, the use of metal continues to increase in commercial buildings and even residential construction. Metal is a durable material that resists corrosion, decay, and structural stress more effectively than wood and other types of building materials.Die Cast Aluminum Light housing

As one of professional manufacturer, HY would like to provide you high quality Die Cast Aluminum Light housing. And we will offer you the best after-sale service and timely delivery.

Waterproof index: IP66 IP67

Seismic resistance index: IK08 IK09 IK10

Material: Aluminum + PC

Die-cast aluminum light housing working temperature (℃): -40-60

Certification EMC, RoHS, CE, FCC, LVD, 3G Vibration, ISO 9001, ISO 14001Camera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.