- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China parts engine Manufacturers, Suppliers, Factory

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for parts engine,oil pump,engine parts,marine engine parts,cylinder head, We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

parts engine, Welcome to visit our company, factory and our showroom where displays various hair solutions that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to deliver you the best service. Be sure to contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Hot Products

machine screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of machine screws fasteners, focusing on different series of fastener products, including stainless steel and carbon steel nuts, screws, bolts, washers and various stamping and die-casting products. Based on our own production capacity, we can provide one-stop product services such as design, customization, production and after-sales according to your needs.

Thread size: M6/M8//M10/M12/M14/M16/More

Surface treatment: galvanized/other

Material: stainless steel

Standard: ISO8677, DIN603, GB14Die Casting Mechanical And Electrical Shroud Fan

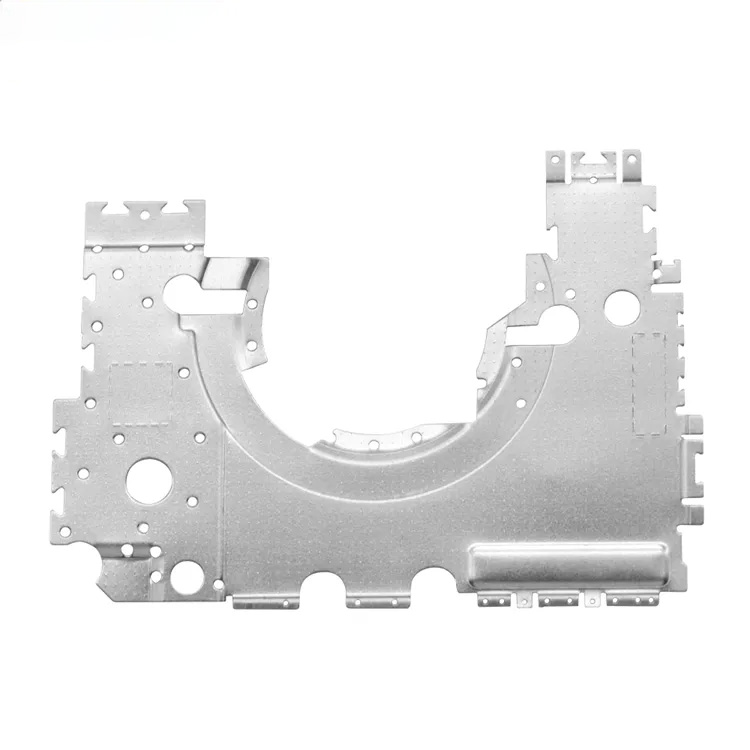

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2Metal Stamping Electronic Wire Assemblies

HY is a Metal Stamping Electronic Wire Assemblies factory that custom-processes metal stamped electronic wire assemblies.The industries served by HY include home appliances, electrical equipment, electronics, and lighting. Nearly 20 years of experience in Precision Metal Stamping.photovoltaic inverter

Xiamen Hongyu Intelligent Technology Co., Ltd. is a national key high-tech enterprise focusing on the research and development, production, sales and service of related components and accessories of renewable energy such as solar energy and wind energy, such as photovoltaic inverter. The company is currently the largest photovoltaic inverter manufacturer in China and has complete independent processing capabilities. The company's current full application scenarios cover users, distributed, and large ground/water surfaces.

Protection level: IP67

Type: pv inverter, solar and power inverter

Size: Customization supported

Material: aluminum, metal, stainless steel, aluminum alloy, galvanized steelStainless steel flat washer

HY developed metal stamped stainless steel flat washers for customers in the medical industry. Made from 17-7 PH stainless steel, this stainless steel gasket has strong corrosion resistance and is not prone to rust, making it ideal for medical use.Die Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.