- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China motor housing casting Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our enhancement strategy for motor housing casting,Aluminum Die-cast Housing,Precision Aluminum Die Casting,Precision Metal Aluminum Die-cast Housing,Copper Brass Aluminum Casting Housing, We welcome all with the shoppers and buddies to call us for mutual rewards. Hope to do further more business along with you.

motor housing casting, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

Hot Products

Casting Clutch Components

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of Casting Clutch Components, covering an area of 12,000 square meters, equipped with machining centers, gantry CNC lathes, laser cutting machines, CNC bending machines and other equipment. The company has more than 70 skilled engineers and professionals. Products are exported to more than 30 countries including the United States, Mexico, Spain, Norway, Morocco and South Korea.

Product Type: Casting Clutch Components

Size: Customization supported

Quality Control: 100% full inspection

Certification: ISO9001/CE/ROHS, IATFMetal Brand Seal

Customized Metal Brand Seal, mirror polished, solid brass HY designs a unique seal taste for you. The iconic "shiny" head is machined from a solid brass blank and coated with an ultra-fine ceramic layer.Stamping Wire Formed Fasteners

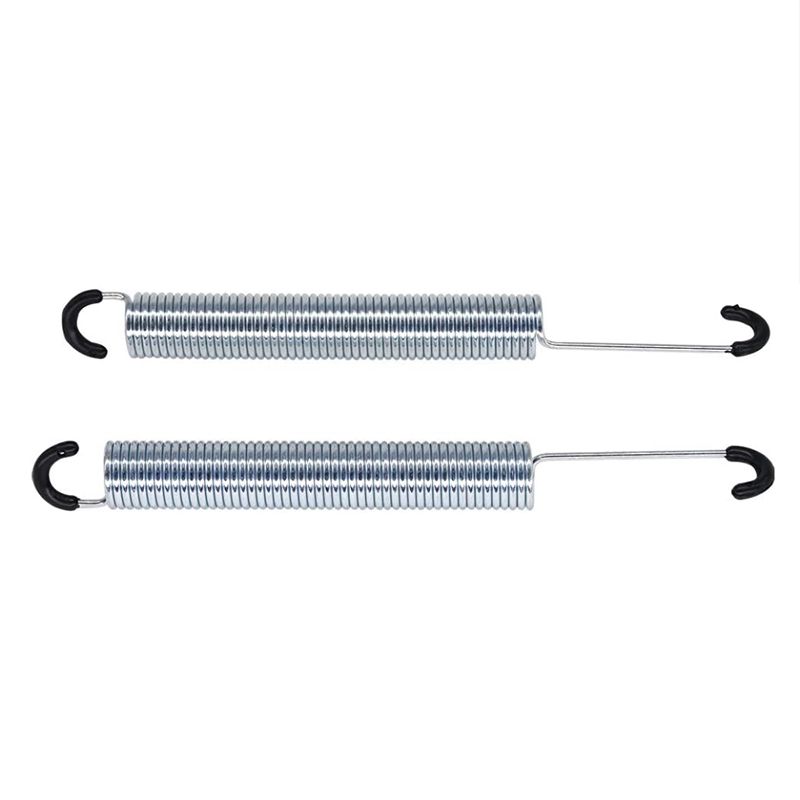

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Metal Stamping Fuse Clips

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirementsstainless steel screws

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in the production of hardware accessories. It is a high-quality enterprise with "professionalism, innovation and service" as its core, and has therefore won the recognition and trust of customers. HY is committed to the research and development, production and sales of stainless steel screws fasteners, including 13 invention patents, 15 utility model patents and 1 design patent, demonstrating our technical expertise and innovation capabilities.

Hardware accessories: screw

Material: stainless steel, steel, brass, titanium, carbon steel, nickel, alloy

Surface treatment: black, galvanized

Quality: 100% full inspection, test and certification can be carried out according to customer special requirementsshutters

Xiamen Hongyu Intelligent Technology Co., Ltd. is a dynamic modern enterprise with more than 10 years of experience in manufacturing aluminum windows and doors and metal shutters. HY's products are available in a variety of colors and sizes, and our product range can be customized according to the customer's plans and requirements. If you are buying shutters for the first time, we will provide professional advice on the selection of profiles. Different regions have different climatic characteristics, so different profiles should be treated differently to meet their diversity, which is related to the durability of doors and windows and each function of absorbing and saving energy.

Types: metal shutters, aluminum window shutters, steel shutters

Customization service: support OEM/ODM customization

Application scenarios: home, hotel, B&B, factory, ventilation