- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Aluminum Die-cast Housing Manufacturers, Suppliers, Factory

Every single member from our large efficiency profits team values customers' requirements and organization communication for Aluminum Die-cast Housing,Precision Aluminum Die Casting,Precision Metal Aluminum Die-cast Housing,Copper Brass Aluminum Casting Housing,Stainless Steel Aluminum Casting Housing, In addition, we would properly guideline the shoppers about the application techniques to adopt our products and solutions as well as the way to select appropriate materials.

Aluminum Die-cast Housing, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to provide our customers more profit, and looking forward to more chance to make business.

Hot Products

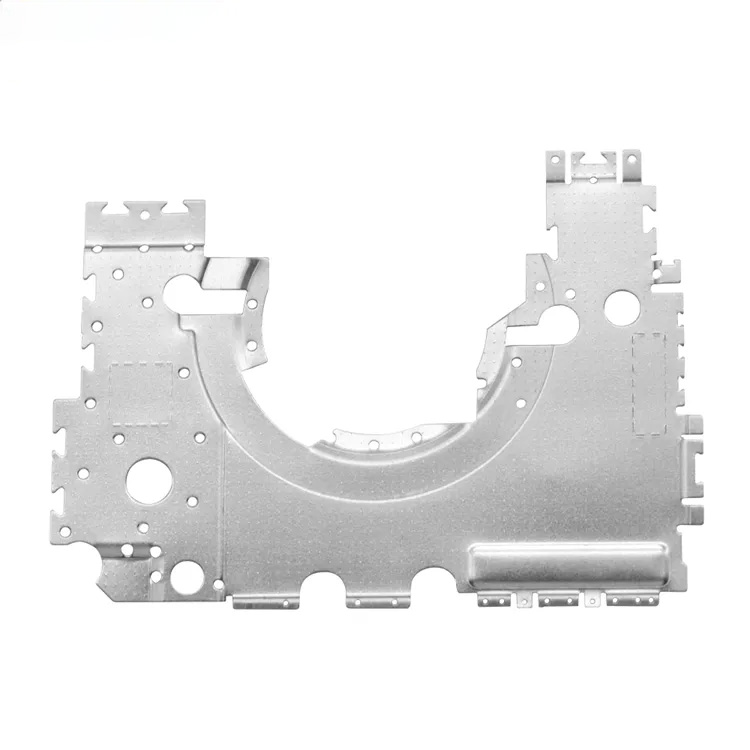

Camera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.Stamping Wire Formed Fasteners

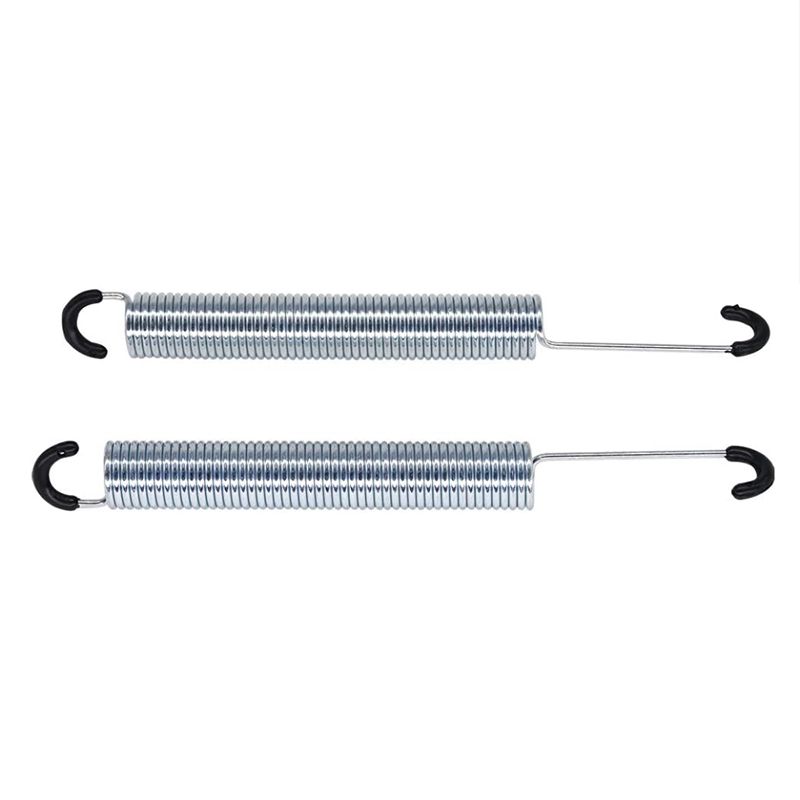

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Galvanized Male And Female Stamping Parts

Hongyu is a factory that uses stamping to Galvanized Male And Female Stamping Parts. Metal stamping uses progressive high speed stamping Die and specialized presses and feeders to cut and form galvanized male and female parts from coils of steel. The metal stamping process is fast and efficient, making it ideal for mass production of metal parts.Stamping Selective Plated Lead Frames

HY is a manufacturer and distributor of Stamping Selective Plated Lead Frames.HY utilizes stamping, plating and overmolding technologies to manufacture high-quality selective plated lead frames and precision components, providing hybrid solutions for sensor and power IC packaging.Inconel Part Oil Stamping

HY is a manufacturer and seller of custom Inconel Part Oil Stamping, Inconel part stampings are used in the petroleum industry and are very popular.crutch

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturing factory that produces various wheelchairs, commode chairs, shower chairs, crutch, walkers and other medical rehabilitation products. With more than 17 years of processing and manufacturing experience, our factory has passed IS013485 and IS09001 quality management, and the products have passed CE certification.

Product type: crutch

Use: medical rehabilitation supplies

Color: matte, metallic, silver