- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China hospital screen room divider Manufacturers, Suppliers, Factory

With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for hospital screen room divider,hospital screen,medical room divider,hospital room dividers,medical privacy screen on wheels, We warmly welcome good friends from all walks of life to cooperate with us.

hospital screen room divider, We have now won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

Hot Products

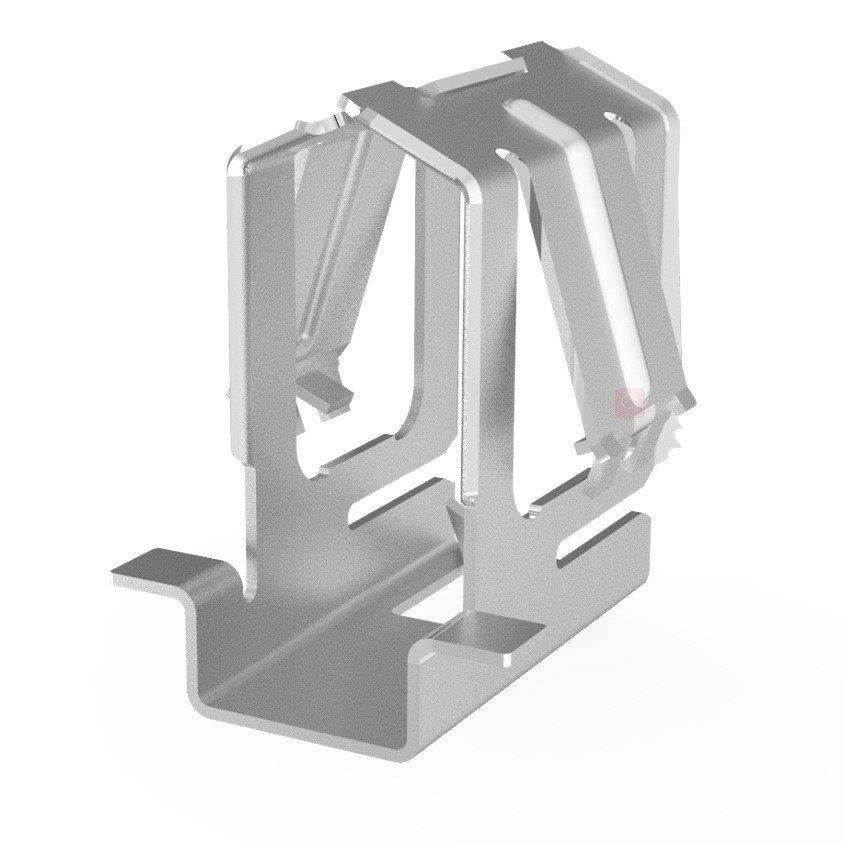

Pc Fan Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is an ISO enterprise specializing in the manufacture of hardware accessories. It has more than 17 years of processing experience. Including pc fan bracket, sheet metal CNC processing, shell, bracket, chassis design, and the production and manufacturing of internal functional parts of products. High quality, on-time delivery, professional design, and one-stop service are the reasons for our long-term cooperation with well-known customers such as HAN's LASER, Formlabs, Samurai, Baxter, VELKASE, etc. As long as you give us the function, performance, and even creativity of the product, we can turn the product from creativity into reality. Welcome to consult immediately.

Item: computer case fan bracket

Certificate: ISO9001:2008

Customization: Support customized OEM serviceDie Casting PWR Housing

HY as a Die Casting PWR Housing manufacturing factory. In a die-cast pressurized water reactor housing, the reactor core heats the water and maintains it under pressure to prevent it from turning into steam. This hot radioactive water flows through tubes in the steam generator.medical tweezers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steelMetal Stamping Fasteners

HY improve and design industrial fasteners by Metal Stamping Fasteners, providing lower-cost precision metal stamping parts, and more efficient alternative solutions. Metal stampings are commonly used in nearly every industry, including electrical, automotive, appliances, and construction.Die Casting Automotive Filter

Die Casting Automotive Filter,HY has extensive experience helping Chinese automakers with prototyping, designing and manufacturing aluminum and zinc alloy die castings.stainless steel rivets

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of all kinds of stainless steel rivets, blind rivets, rivet nuts, pressure rivets, national standard fasteners, non-standard fasteners, and riveting tools. The company has a complete set of advanced production equipment and automatic lathes, and adopts international advanced standards for production. "Zero defects, create brands" is HY's purpose. We hope to establish a good cooperative relationship with domestic and foreign customers on the basis of equality, mutual benefit and common development.

Surface treatment: natural, black, galvanized, other

Material: stainless steel, aluminum, brass, special alloy

Processing technology: stamping