- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Force Sensitive Resistor Manufacturers, Suppliers, Factory

Persisting in "High good quality, Prompt Delivery, Competitive Price", we now have established long-term cooperation with shoppers from both of those overseas and domestically and get new and outdated clients' superior comments for Force Sensitive Resistor,Sensor Components Online,Linear Potentiometer Sensor,Top Sensor Component,Affordable Sensor Components, With a wide range, good quality, reasonable prices and good service, we will be your best business partner. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Force Sensitive Resistor, At existing our sales network is growing continually, improving service quality to meet customer's demand. If you are interested in any goods , be sure to contact us at anytime. We have been looking forward to forming successful business relationships with you in near future.

Hot Products

Metal Stamping Automotive Catalytic Converter

HY is China manufacturer & supplier who mainly produces Metal Stamping Automotive Catalytic Converter with many years of experience. Hope to build business relationship with you.Casting Pulleys

HY is famous for its low price and good quality in the stamping industry. HY Casting Pulleys in almost every possible custom diameter and bore size.Aluminum Alloy Die Casting

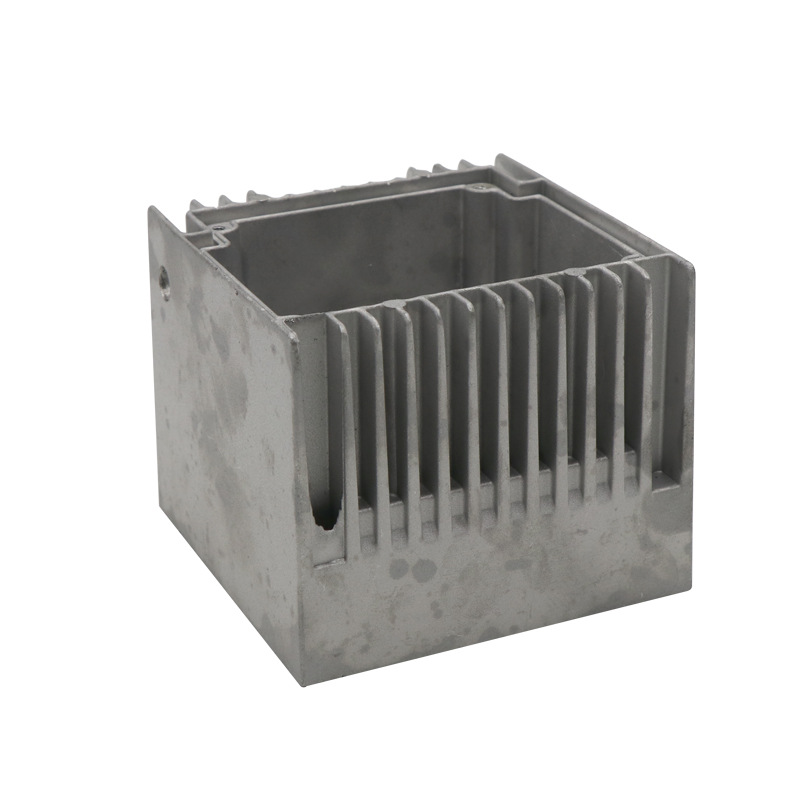

Xiamen Hongyu Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 daysMetal Stamping Industry Springs

Metal Stamping Industry Springs have been used as an important part of many areas of modern life. Industrial springs produced by HY are affordable. Therefore, designing springs with available diversity has become critical for both commercial products and industrial applications.Camera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.Die Casting Chassis

HY is committed to producing Die Casting Chassis to provide optimal strength and is a manufacturer and trader of stamping and die-cast products. enhance the power of the frame. The materials used are carefully and rigorously selected to extend the service life.