- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

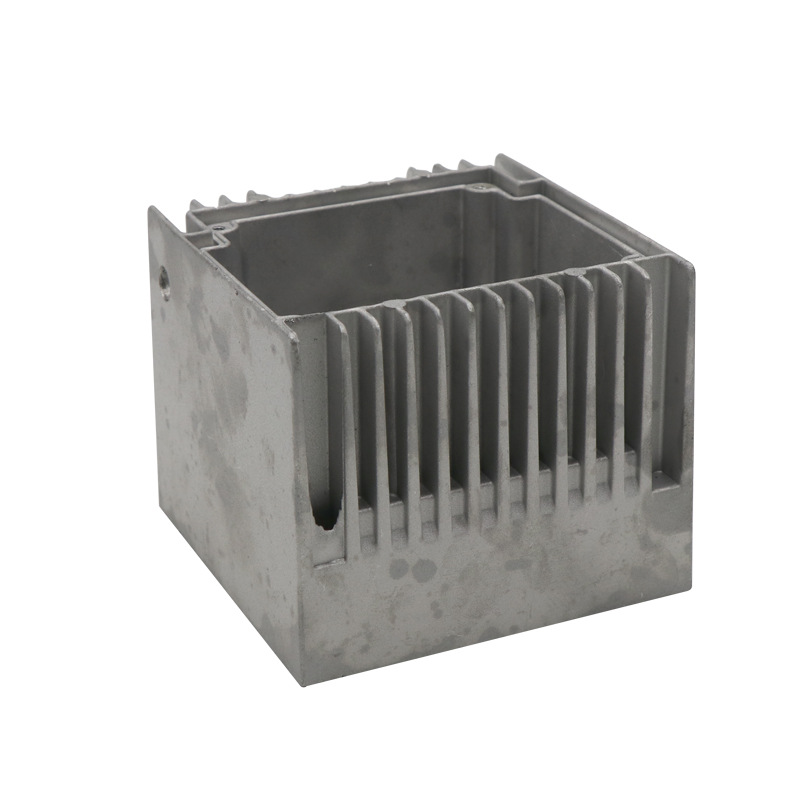

China dyson supersonic filter cage Manufacturers, Suppliers, Factory

Being a result of ours specialty and service consciousness, our corporation has won a very good status amid buyers all over the world for dyson supersonic filter cage,dyson hair dryer filter replacement,dyson hair dryer filter,dyson supersonic filter,dyson hairdryer filter, Sincerely stay up for serving you from the in the vicinity of future. You are sincerely welcome to go to our company to talk company face to face with each other and create long-term co-operation with us!

dyson supersonic filter cage, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we offer, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and comprehensive parameters and any other info weil be sent for you timely for the inquiries. So remember to get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we're likely to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Hot Products

Brake Handle

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional die-cast brake handle factory with good product quality and low price. HY has independent R&D and manufacturing capabilities, and attaches great importance to quality control. Our products have obtained CE, FCC, and RoHS certifications.

Bike brake handle manufacturing process: metal mold casting

Surface treatment: sandblasting, powder spraying

Material: aluminum alloy

Tolerance: 0.1mm

Proofing cycle: 3-7 daysDie Casting Home Security Lockbox

Welcome to wholesale Die Casting Home Security Lockbox from us,HY is a factory that provides first-class stamping and die-casting services. Hongyu Intelligent technology zinc alloy die casting home security lock box keeps your cash and valuables safe and secure, giving you peace of mind!Medical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

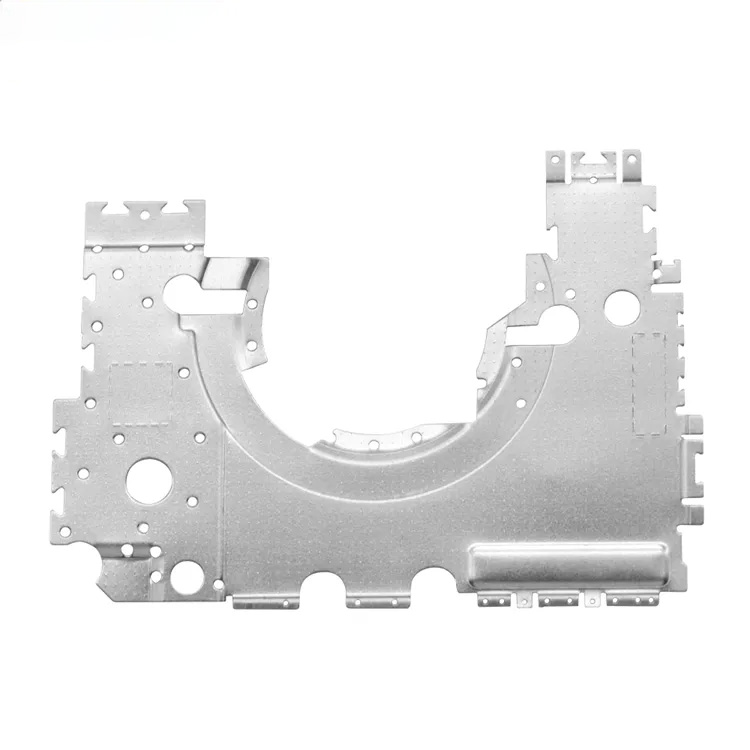

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentmachine screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional manufacturer of machine screws fasteners, focusing on different series of fastener products, including stainless steel and carbon steel nuts, screws, bolts, washers and various stamping and die-casting products. Based on our own production capacity, we can provide one-stop product services such as design, customization, production and after-sales according to your needs.

Thread size: M6/M8//M10/M12/M14/M16/More

Surface treatment: galvanized/other

Material: stainless steel

Standard: ISO8677, DIN603, GB14Pc Fan Bracket

Xiamen Hongyu Intelligent Technology Co., Ltd. is an ISO enterprise specializing in the manufacture of hardware accessories. It has more than 17 years of processing experience. Including pc fan bracket, sheet metal CNC processing, shell, bracket, chassis design, and the production and manufacturing of internal functional parts of products. High quality, on-time delivery, professional design, and one-stop service are the reasons for our long-term cooperation with well-known customers such as HAN's LASER, Formlabs, Samurai, Baxter, VELKASE, etc. As long as you give us the function, performance, and even creativity of the product, we can turn the product from creativity into reality. Welcome to consult immediately.

Item: computer case fan bracket

Certificate: ISO9001:2008

Customization: Support customized OEM serviceGaming Keyboard

HY is a manufacturer of gaming mechanical keyboards. The stamped gaming keyboard produced is a high-end product specially designed for gamers, aiming to create the most accurate, comfortable and efficient gaming experience for players. Made with high-quality materials and advanced technology, this keyboard is both durable and high-performance.