- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Die Cast Stage Light Stand Manufacturers, Suppliers, Factory

Dependable high-quality and good credit rating standing are our principles, which will help us at a top-ranking position. Adhering into the tenet of "quality first, consumer supreme" for Die Cast Stage Light Stand,Stage Spotlight With Stand,Lighting Stand Fasteners,Scaffolding Connector,Scaffold Pipe Fittings, To learn more about what we can do for you, contact us at any time. We look forward to establishing good and long-term business relationships with you.

Die Cast Stage Light Stand, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Hot Products

Spark Plug

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading and well-known manufacturer of high-end automotive engine spark plugs. Its electrodes are made of high-quality metal iridium and platinum, suitable for various cars, such as CORROLA, RAV4, CAMRY, TOYOTA VOIS, ALPHA car engines. Our spark plugs are made of high-quality raw materials and have excellent engine performance.

Main products: double iridium, double platinum, iridium platinum, single iridium, single platinum, nickel, CNG, LPG special vehicle high-end spark plugs

Electrode material: iridium

OEM customization: supportDie Casting Lower Cover

HY is a manufacturer and supplier of cast lower covers, using presses from 25 tons to 400 tons, and can meet customer needs whether it is precision or large Die Casting Lower Cover.metal phone cases

Xiamen Hongyu Intelligent Technology Co., Ltd. is an integrated factory of industry and trade. We support the production and customization of metal phone cases. You can provide samples or drawings of metal phone cases. HY has professional mechanical processing and system testing service processes. HY has a complete production line to ensure that it can meet the monthly production capacity needs and provide one-stop services, covering furniture accessories, electronic accessories, medical equipment accessories and other fields. HY is confident to establish long-term cooperation to provide customers with competitive solutions.

ODM service time: It can be completed in 3-5 days at the fastest.

Drawing design service: Support customized design service.

Quality certificate: ISO 9001, ISO14001, REACH, RoHs

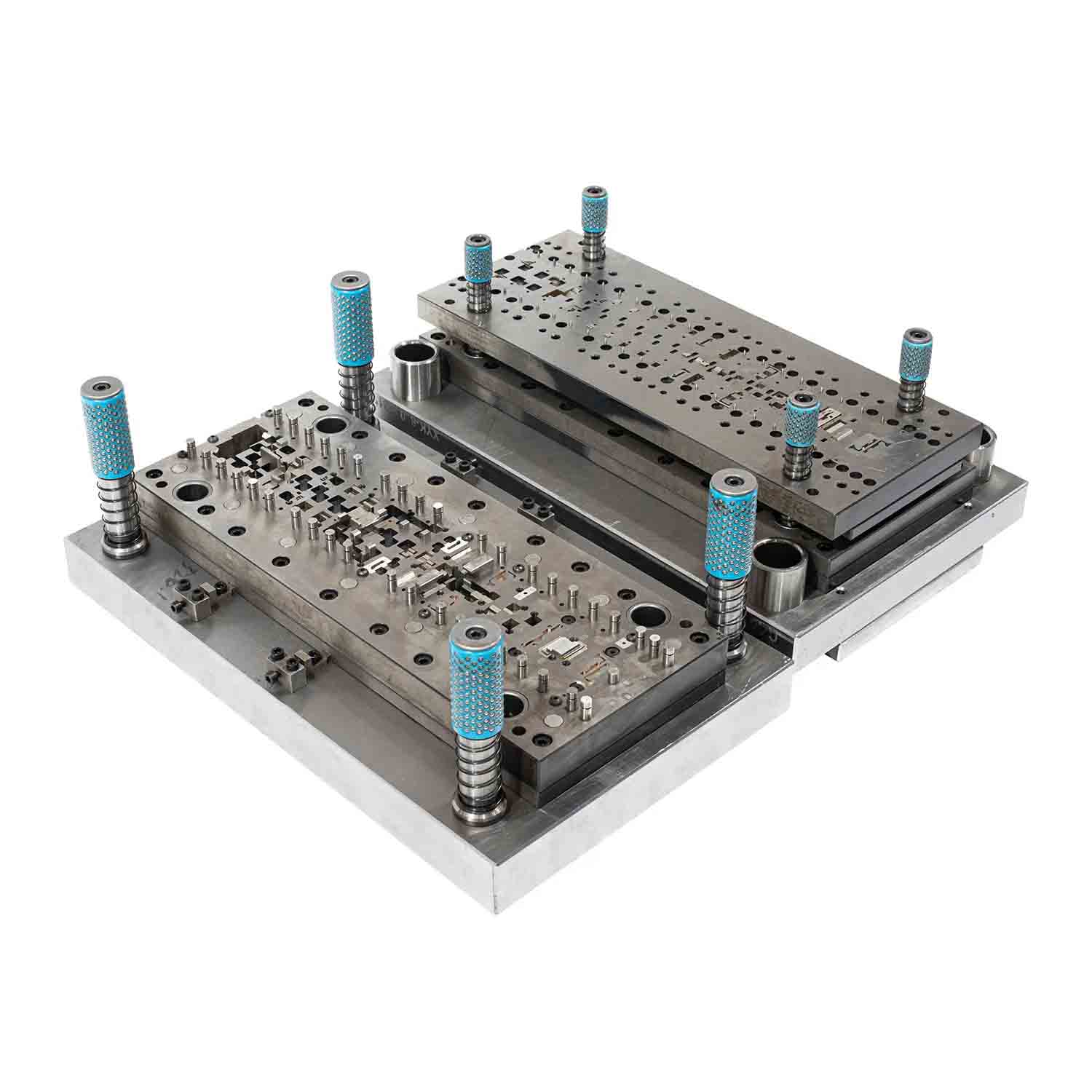

Tolerance: 0.02Custom Metal Stamping Dies

Xiamen Hongyu Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.Casting Engine Components

HY supplies Casting Engine Components to European and American customers and is a global factory supplier. Today's engines and engine components require lightweight, high strength, pressure resistance and high machinability. Aluminum engine casting offers all of these advantages, improving engine performance while providing additional advantages over traditional construction.battery trays

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in battery tray for boat, car battery holder, battery trays and other products. Including research and development, production. Sales, protection, to provide customers with high-quality solutions. With multiple qualifications and patents, we always put customer service and product quality first. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various models of cars according to customer needs.

Process: casting, precision machining, welding assembly

Surface treatment: pre-galvanizing, passivation

Model: customized