- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Scaffolding Connector Manufacturers, Suppliers, Factory

Our organization sticks for the principle of "Quality will be the life of your business, and name may be the soul of it" for Scaffolding Connector,Stage Spotlight With Stand,Die Cast Stage Light Stand,Lighting Stand Fasteners,Scaffold Pipe Fittings, Leading the trend of this field is our persistent objective. Supplying first class solutions is our intention. To create a beautiful upcoming, we wish to cooperate with all close friends in the home and overseas. Should you have got any interest in our products and solutions, remember to never wait to call us.

Scaffolding Connector, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which might be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Hot Products

Die Casting Chassis

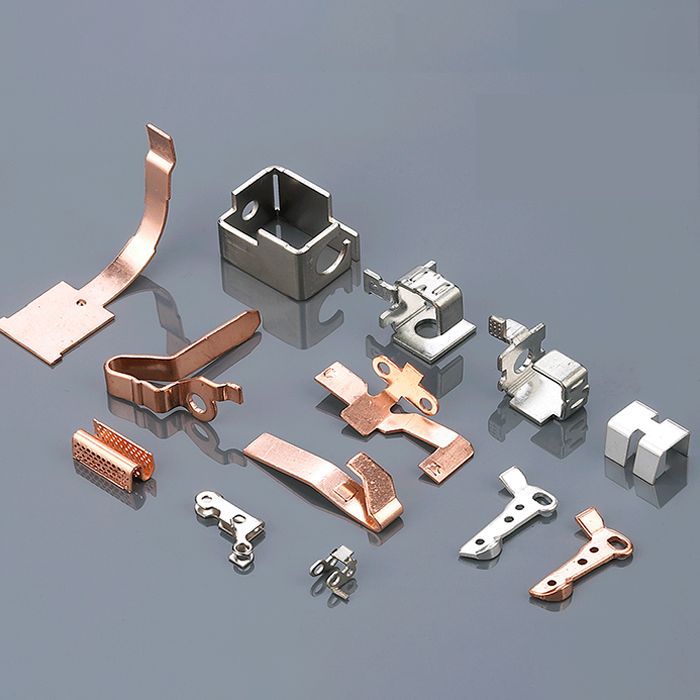

HY is committed to producing Die Casting Chassis to provide optimal strength and is a manufacturer and trader of stamping and die-cast products. enhance the power of the frame. The materials used are carefully and rigorously selected to extend the service life.Metal Stamping Fuse Clips

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirementsCasting Seeder Housing

HY's die Casting Seeder Housing are used in most different manufacturing areas, from machine manufacturing, Seeder housings and the oil and gas industry to consumer goods and decorative/artistic castings.Die Cast Aluminum Light housing

As one of professional manufacturer, HY would like to provide you high quality Die Cast Aluminum Light housing. And we will offer you the best after-sale service and timely delivery.

Waterproof index: IP66 IP67

Seismic resistance index: IK08 IK09 IK10

Material: Aluminum + PC

Die-cast aluminum light housing working temperature (℃): -40-60

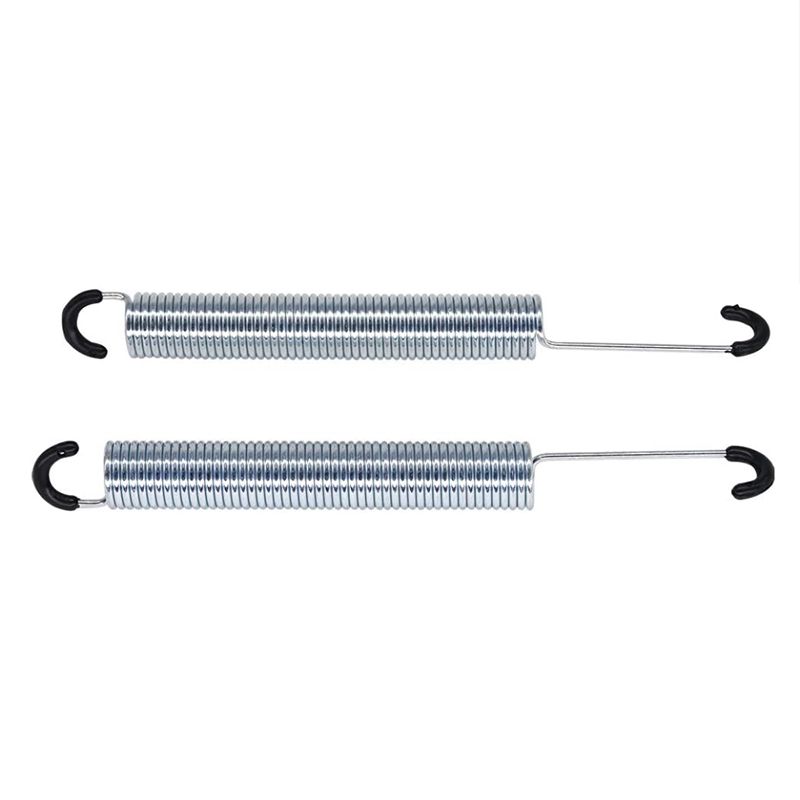

Certification EMC, RoHS, CE, FCC, LVD, 3G Vibration, ISO 9001, ISO 14001Stamping Wire Formed Fasteners

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Zinc Die-Cast Door Handle

Product name: Precision machining of zinc die-cast door handle

Material: Zinc alloy

Product Name: Precision machined zinc die-cast door handle

Usage: Train door handles, construction decoration door handles

Sample: 42 days for mold opening + proofing