- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Die cast motorcycle brake handle Manufacturers, Suppliers, Factory

With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for Die cast motorcycle brake handle,bike brake handle,paul brake levers,bicycle brake levers,hydraulic levers, We sincerely welcome mates to negotiate organization and start cooperation. We hope to affix hands with good friends in different industries to produce a fantastic long term.

Die cast motorcycle brake handle, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We're looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

Hot Products

Motor Base

Xiamen Hongyu Intelligent Technology Co., Ltd. has always adhered to the business policy of production specialization, product branding, market internationalization, and global layout, and supplies Motor Base and other Precision aluminum casting to domestic and foreign markets and customers with high-quality products.

Product name: Motor Base

Application: Smart home, construction machinery, servo motor

Customization: Support pricing processing servicesStamping Wire Formed Fasteners

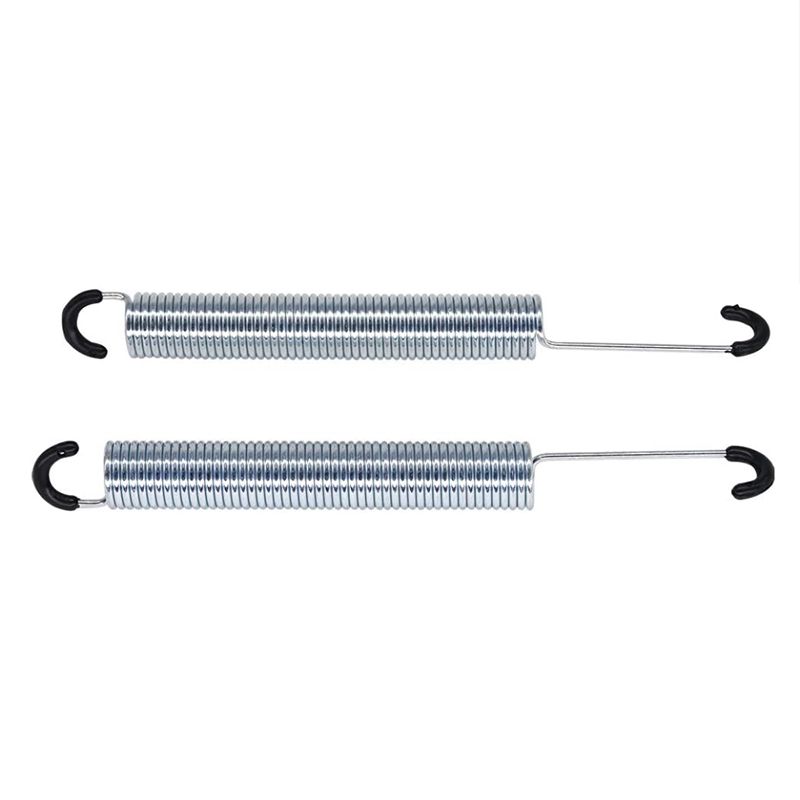

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Casting Seeder Base-Plates

HY is a Casting Seeder Base-Plates manufacturer and seller of seeder base plates in China. High-precision castings are people’s first choice.medical wheelchair

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production and supply of high-quality medical care products. HY has established a good reputation through high-quality and professional production, quality control and customer service. We provide a variety of hospital or home care products, including wheelchairs, trolleys, bathroom series, walkers, crutches and beds, etc.

Product type: medical wheelchair

Material: carbon steel, aluminum alloy, stainless steel, carbon fiber

Processing method: precision stamping

Load limit: 136KG

Recommended population: patients with impaired walking function, the elderly, patients in rehabilitation periodInconel Part Oil Stamping

HY is a manufacturer and seller of custom Inconel Part Oil Stamping, Inconel part stampings are used in the petroleum industry and are very popular.Die Casting Exhaust Pipe

HY is a factory that Die Casting Exhaust Pipe exhaust pipes for automobile parts.Hongyu custom-designed aluminum die-cast motorcycle exhaust pipes, die-cast aluminum five-axis machine-made racing exhaust pipes, motorcycle mufflers, car exhaust pipes.