- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China paul brake levers Manufacturers, Suppliers, Factory

We always think and practice corresponding to the change of circumstance, and grow up. We goal at the achievement of a richer mind and body and also the living for paul brake levers,bike brake handle,bicycle brake levers,hydraulic levers,dual brake lever for bicycle, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

paul brake levers, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

Hot Products

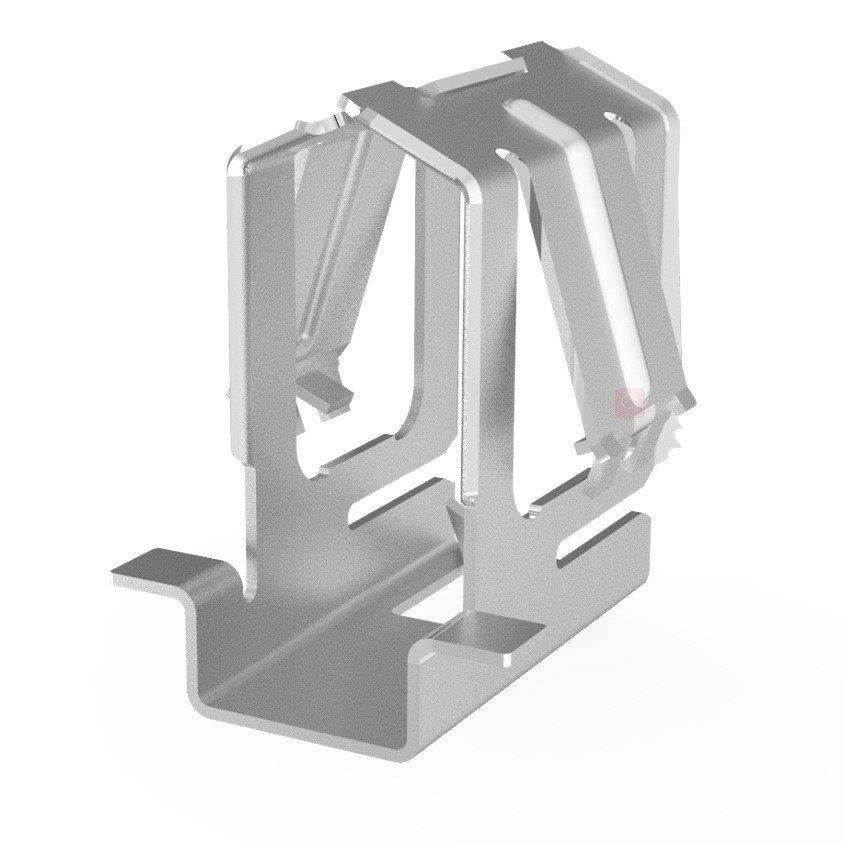

Camera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.Sensor Components

HY is a manufacturer and seller of sensor components. HY's appliance accessory sensor components are available in a variety of materials, including deep-drawn aluminum, copper, mild and high carbon steel, and various stainless steels.Medical Equipment Base

You can purchase Medical Equipment Base from HY with confidence, as we are a proficient producer of high-quality Medical Equipment Base. We promise to provide you with the best after-sale service and prompt delivery.

Product name: Precision sheet metal base for medical equipment

Material: Material thickness electrolytic plate

Surface treatment: electroplating anodizing

Product size: non-standard customization, customization according to drawings

Processing technology: sheet metal stamping, laser cutting, bending and riveting applications

Application areas: medical equipment automation equipmentoil sump

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional auto parts manufacturer that produces oil coolers, intake manifolds, engine valve covers, and oil sump engine accessories. At present, it has many cooperative customers in the United States, Europe, Russia and other regions.

Product name: oil sump

Material: aluminum, stainless steel, titanium, special alloys, etc.

Application scenarios: automotive industry, industrial equipment manufacturingAluminum Alloy Die Casting

Xiamen Hongyu Intelligent Technology Co., Ltd. focuses on aluminum alloy die casting and die cast metal die casting, and has 17 years of relevant processing experience. HY supports one-stop services from mold design, manufacturing, die casting deburring, polishing, CNC processing to surface treatment. It has a professional design engineering team and mold development team. The fastest mold production takes only 7 days, helping customers to get products quickly and seize the market.

Processing services: aluminum alloy die casting, die cast metal, die cast alloys, etc.

Proofing cycle: 3-7 days to complete quickly

Processing type: support OEM/ODM customization

Mold opening cycle: 7-12 daysInconel Part Aerospace Stamping

HY is a factory in the stamping industry. HY is the industry leader in custom inconel part aerospace stamping for use in the electronics, construction, aerospace, defense and medical industries.