- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

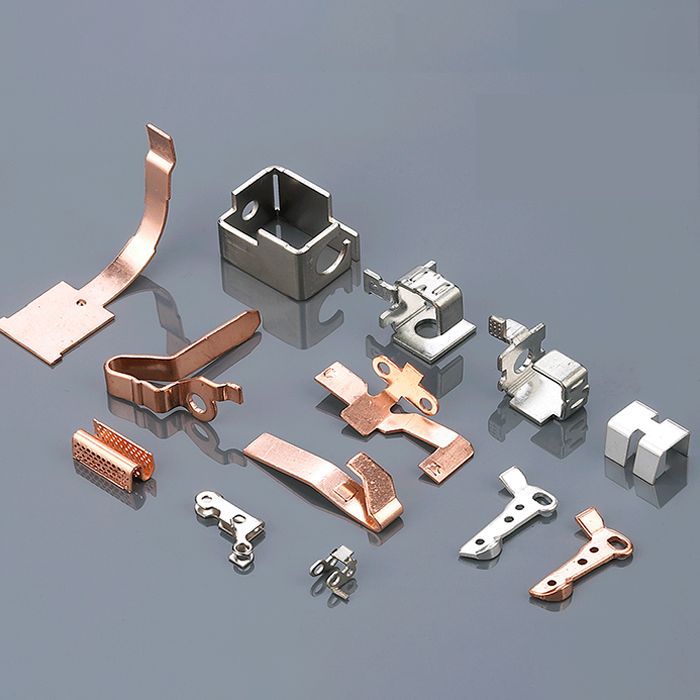

China Die cast filter manufacturer Manufacturers, Suppliers, Factory

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Die cast filter manufacturer,small drip coffee maker,single cup drip coffee maker,large filter coffee machine,Zinc alloy die-cast coffee machine accessories, We hope we can have a friendly relationship with businessman from all over the world.

Die cast filter manufacturer, We've been confident that we are able to offer you with opportunities and might be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of merchandise that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

Hot Products

hospital screen

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional supplier of hospital screens, hospital beds (manual and electric), hospital stretchers, medical cabinets, hospital trolleys, maternity beds, cribs and other medical care products. HY has a mature import and export system and complete medical certification qualifications. Its current overseas markets include Europe, the United States, the Middle East and other regions.

Color: green, blue, pink, according to demand

Application: hospital, pharmacy, laboratory

Material: stainless steel, waterproof cloth, etc.

Roller: optionalCasting Medical Valve

HY is a medical valve factory from China. Casting Medical Valve is used to change the channel cross-sectional area and medium flow direction. It has functions such as diversion, cut-off, regulation, throttling, check, diversion or overflow pressure relief. Medical valve castings are control components in pipeline fluid delivery systems. Quality Control: 100% QC Inspection

Certification: ISO9001/CE/ROHS

Size: Support OEM/ODM customizationDie Casting Mechanical And Electrical Shroud Fan

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2stainless steel lid

HY's stainless steel lid is a high-quality product made of high-quality 304 stainless steel. With its excellent strength and durability, it is ideal for sealing a variety of jars or bottles. HY's advanced stamping process ensures that the lid is seamless, well-formed and void-free, making it extremely corrosion-resistant. This production design makes it a versatile product that can be used in a wide range of applications from kitchen utensils to industrial containers.Barbecue Grill

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business. Stamping type: metal stamping processing Grill material: stainless steel plate Processing type: metal forming Process: stamping, bending, trimming, forming, blanking Surface treatment: electroplating Proofing cycle: 8-15 daysself tapping screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of fasteners and curtain wall accessories. It produces and sells stainless steel self tapping screws, machine screws, nuts, bolts, rivets, washers, anchors, stainless steel undercut anchors, aluminum extrusions, expansion screws and other standard or non-standard fasteners and curtain wall accessories. HY has a complete quality management system, advanced quality testing equipment and a professional quality management team. The product quality adopts batch traceability management.

Material: brass, stainless steel, steel, aluminum, nickel, bronze

Surface treatment: zinc, blackening, galvanizing, zinc-aluminum coating, chrome plating, Ruspert

Screw head type: pan, large round flat head, flat top, oval, round, hexagonal, hexagonal washer

Processing technology: stamping cold heading