- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China car insurance lower cover manufacturer Manufacturers, Suppliers, Factory

We're going to make each individual work being remarkable and ideal, and accelerate our steps for standing during the rank of worldwide top-grade and high-tech enterprises for car insurance lower cover manufacturer,lower bumper cover,lower cover,lower engine cover,car insurance lower cover, Welcome all nice buyers communicate details of products and ideas with us!!

car insurance lower cover manufacturer, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

Hot Products

solar mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of solar photovoltaic support systems in the new energy industry. These products have been sold to more than 100 countries and regions including the United States, the European Union, Australia, the Middle East, South Africa, Japan and Southeast Asia, and have been recognized by customers at home and abroad. HY can produce according to national technical standards according to customer needs. All performance indicators meet national standards and can provide complete qualification certification documents. Providing customers with high-quality, cost-effective products and excellent after-sales service is our mission and commitment to customers.

Product type: solar mounting system, ground mount solar

Processing services: stamping, die-casting, bending, welding, punching, cutting

Thickness: 0.5-3.0mm or customer requirements

Length: 1m-12m or customer requirementsTransmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.Metal Stamping Fuse Clips

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of Metal Stamping Fuse Clips. The function of Metal Stamping Fuse Clips is to connect the circuit and the fuse. It is part of the protection circuit and can facilitate the installation and removal of the fuse. HY specializes in the production of various types of metal stamping parts and sheet metal processing parts, and has been committed to the research and development and improvement of related technologies. For the stamping business, we have strong mold, design and production capacity, can design and manufacture new molds, respond to changes very quickly, and provide solutions for various difficult metal stamping parts.

Product Type: Metal Stamping Fuse Clips, Brass Fuse Clips, Pcb Mount Fuse Clips

Surface treatment: anodizing, polishing, electroplating, PVD coating, galvanizing

Drawing format: CAD, 3D (stp, igs, dfx). PDF

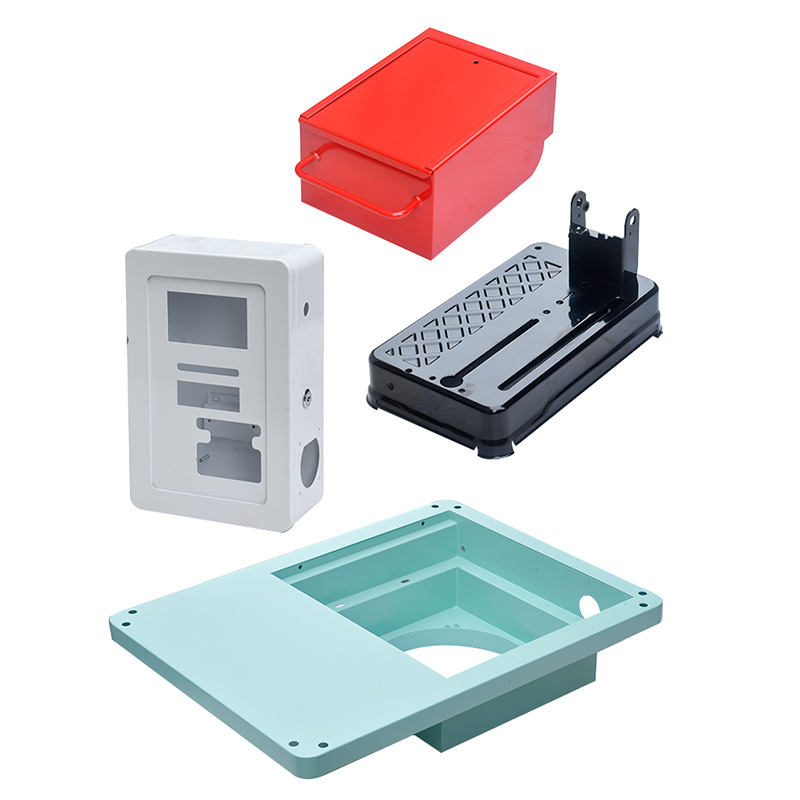

Tolerance: +-0.01-0.05 mm can be more precise, according to your requirementsStamping Photovoltaic Junction Box

HY is a factory that specializes in customizing and Stamping Photovoltaic Junction Box.The photovoltaic junction box is an important part of the solar panel. The junction box is the housing on the module where the PV strings are electrically connected. Solar panel junction box. Most junction box manufacturers are currently located in China.Heat Sink

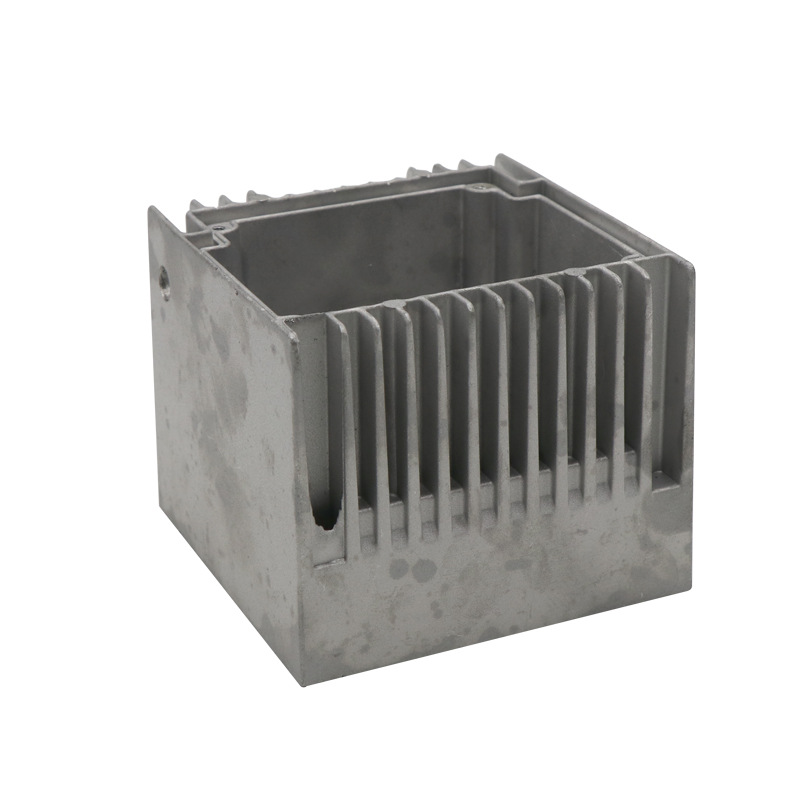

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.Custom Metal Stamping Dies

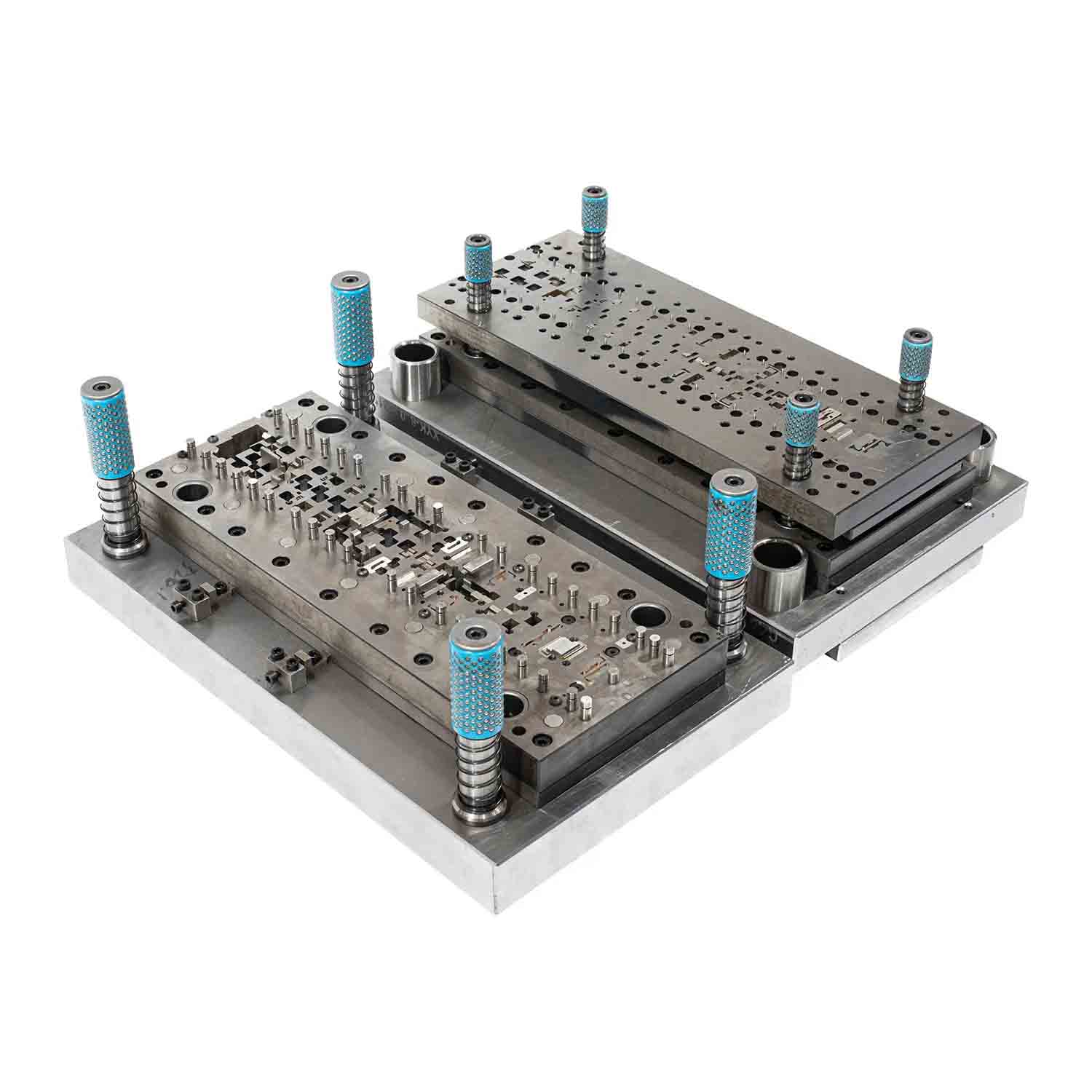

Xiamen Hongyu Intelligent Technology Co., Ltd.'s Custom Metal Stamping Dies are widely used in the automotive, medical and aerospace industries, focusing on precision tools for producing high-quality metal parts. Custom Metal Stamping Dies are usually made of high-strength materials such as steel or carbide, and HY can customize the design according to the specific needs of each customer.

Surface treatment: nickel plating, tin plating, zinc plating, chrome plating, heat treatment, electroplating, etc.

Design file format: dwg, dxf, step, x_t, top, igs

Mold life: Under normal use, the life of the mold can reach at least 300,000 cycles.