- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

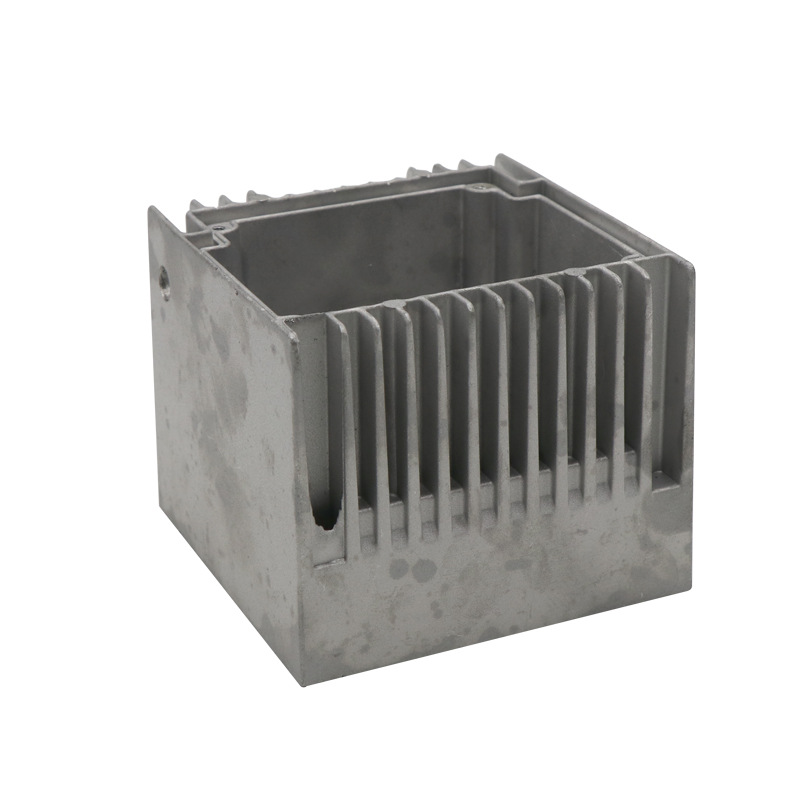

China lower engine cover Manufacturers, Suppliers, Factory

Generally customer-oriented, and it's our ultimate focus on to become not only essentially the most trustworthy, trustable and honest provider, but also the partner for our clients for lower engine cover,lower bumper cover,lower cover,car insurance lower cover,car insurance lower cover manufacturer, Welcome to setup long-term romantic relationship with us. Best Value Permanently Top quality in China.

lower engine cover, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified solutions, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Hot Products

stroller frame for car seat

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company that designs, develops, produces, sells and provides after-sales services. As an exporter of Chinese baby-related industries, it has exported stroller frames for car seats to more than 20 countries around the world. HY has always taken design, research and development and strong after-sales services as the core of our strategy, strictly controlling each product to ensure the customer's after-sales experience. HY welcomes global customers to discuss cooperation.

Type: Stroller frame for car seat

Fabric: Oxford cloth, high-grade leather, etc.

Material: Aluminum alloy, high carbon steel, special alloys support customization

Application scenarios: outdoor/home/camping/multi-purpose passenger cars/RVs/family cars, etc.

Processing technology: metal die-castingBarbecue Grill

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business. Stamping type: metal stamping processing Grill material: stainless steel plate Processing type: metal forming Process: stamping, bending, trimming, forming, blanking Surface treatment: electroplating Proofing cycle: 8-15 daysCar Differential

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of automotive parts for heavy and light vehicles at home and abroad. Including drive axles, suspension components, gearboxes, Car Differential and other products. HY In order to ensure product quality, we have imported advanced production equipment and testing equipment, including American HASS lathes, Japanese FANUC manipulators, three-dimensional coordinate measuring machines, etc. We welcome inquiries and feedback from customers at home and abroad.

Application range: automotive transmission, industrial machinery

Surface treatment: carbonization, sandblasting, can be customized according to customer needs

Processing technology: die castingself tapping screws

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturer specializing in the production of fasteners and curtain wall accessories. It produces and sells stainless steel self tapping screws, machine screws, nuts, bolts, rivets, washers, anchors, stainless steel undercut anchors, aluminum extrusions, expansion screws and other standard or non-standard fasteners and curtain wall accessories. HY has a complete quality management system, advanced quality testing equipment and a professional quality management team. The product quality adopts batch traceability management.

Material: brass, stainless steel, steel, aluminum, nickel, bronze

Surface treatment: zinc, blackening, galvanizing, zinc-aluminum coating, chrome plating, Ruspert

Screw head type: pan, large round flat head, flat top, oval, round, hexagonal, hexagonal washer

Processing technology: stamping cold headingelectric hospital bed

Xiamen Hongyu Intelligent Technology Co., Ltd. is a comprehensive medical care enterprise covering R&D, production, sales and after-sales service. It combines processing technology with national environmental certification materials and has a series of product production lines covering intermediate care beds, operating beds, electric hospital beds, etc. HY is committed to promoting medical care into an era of intelligent innovation, giving patients and medical staff more health and humanistic care.

Material: medical grade stainless steel, aluminum alloy, ABS engineering plastics

Product type: electric hospital bed

Product use: hospital home furniture nursing bed

Product application scenario: hospital, nursing homeStamping Photovoltaic Junction Box

HY is a factory that specializes in customizing and Stamping Photovoltaic Junction Box.The photovoltaic junction box is an important part of the solar panel. The junction box is the housing on the module where the PV strings are electrically connected. Solar panel junction box. Most junction box manufacturers are currently located in China.