- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Aluminum alloy die casting mold Manufacturers, Suppliers, Factory

HY is a professional Aluminum alloy die casting mold manufacturers and suppliers in China. Welcome to our factory to buy Aluminum alloy die casting mold. Our high quality products is not only made in China and we have quotation.

Hot Products

Stainless Steel Quick Connect

Product Name:Stainless Steel Quick Connect

Material: 304, 316, 201, 430

Proofing Cycle: 4-7 days

Molding Process: Gravity Casting

Certification: ISO9001:2015

Surface Treatment: Polishing, Brushing, Electroplating, Powder Spraying, Electrophoresis, Sandblasting, Spray PaintingCasting Turbine Component

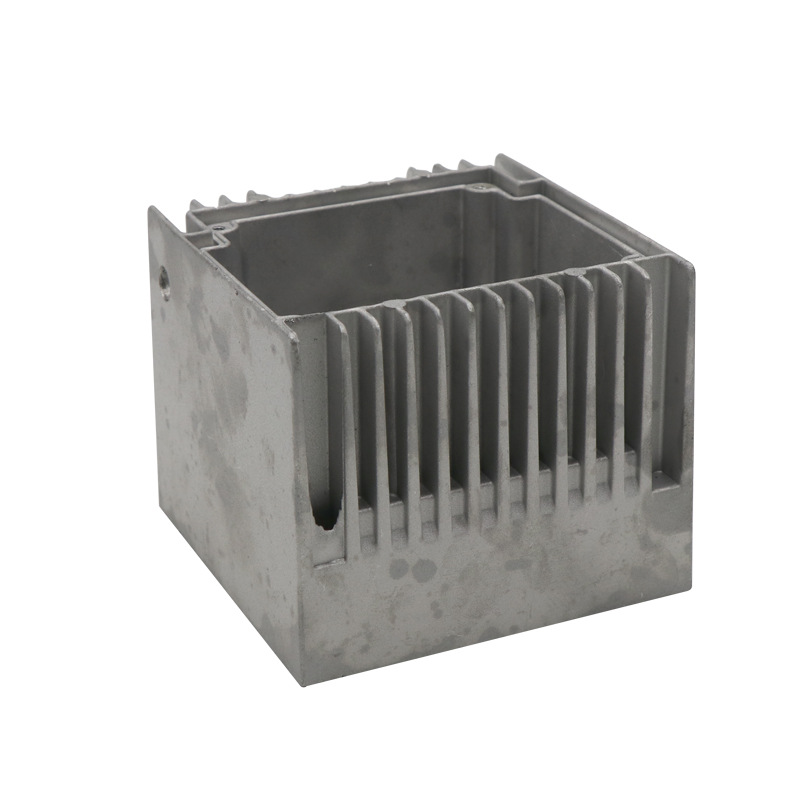

Hongyu is a manufacturer of Casting Turbine Component. Turbines are composed of various components that work together to convert the energy of high-temperature, high-pressure airflow into mechanical energy.Die Casting PWR Housing

HY as a Die Casting PWR Housing manufacturing factory. In a die-cast pressurized water reactor housing, the reactor core heats the water and maintains it under pressure to prevent it from turning into steam. This hot radioactive water flows through tubes in the steam generator.Aluminum Die Casting Flashlight Lighting

HY is a factory that Aluminum Die Casting Flashlight Lighting high-precision stamping and die-casting.Die casting has proven to be an effective method of producing different parts using different materials: copper, zinc and aluminum alloys. Aluminum die casting various properties make it a good metal for die casting.oil sump

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional auto parts manufacturer that produces oil coolers, intake manifolds, engine valve covers, and oil sump engine accessories. At present, it has many cooperative customers in the United States, Europe, Russia and other regions.

Product name: oil sump

Material: aluminum, stainless steel, titanium, special alloys, etc.

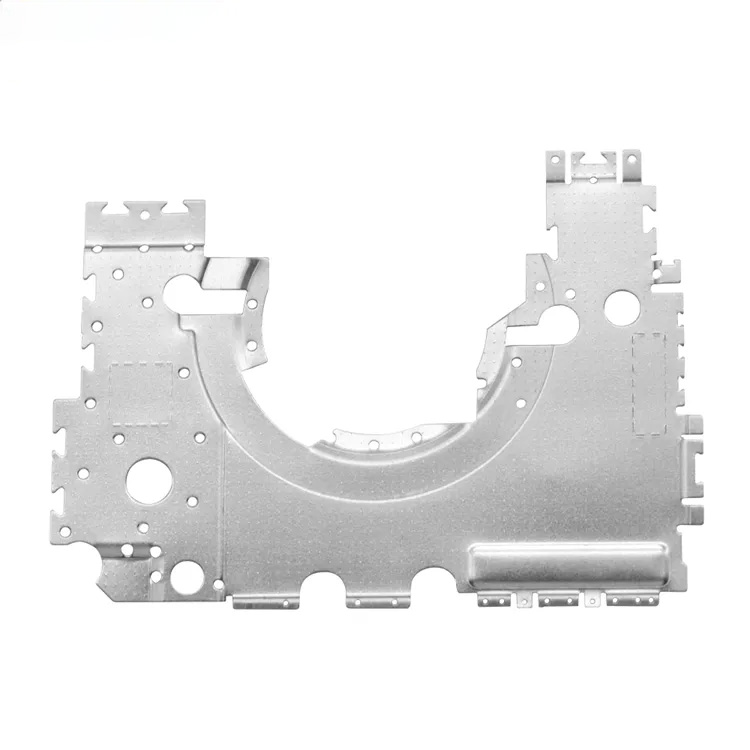

Application scenarios: automotive industry, industrial equipment manufacturingMobile Phone Stainless Steel Stamping Parts

HY sixteen years of industry experience Material: SUS301 Mobile Phone Stainless Steel Stamping Parts specifications: customized according to customer requirements Material characteristics: complies with ROHS, SGS testing Qualification certification: ISO9001 & IATF16949