- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China windscreen wipers Manufacturers, Suppliers, Factory

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for windscreen wipers,windshield wiper,wiper blades,wipers,windscreen wiper blades, We're one from the largest 100% manufacturers in China. Several large trading corporations import goods from us, so we will supply you with the most effective price tag with all the same quality if you are interested in us.

windscreen wipers, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We have been looking for the wholesale, Drop ship. Please contact us if you are interesting our items. Hope to do business with you all. High quality and fast shipment!

Hot Products

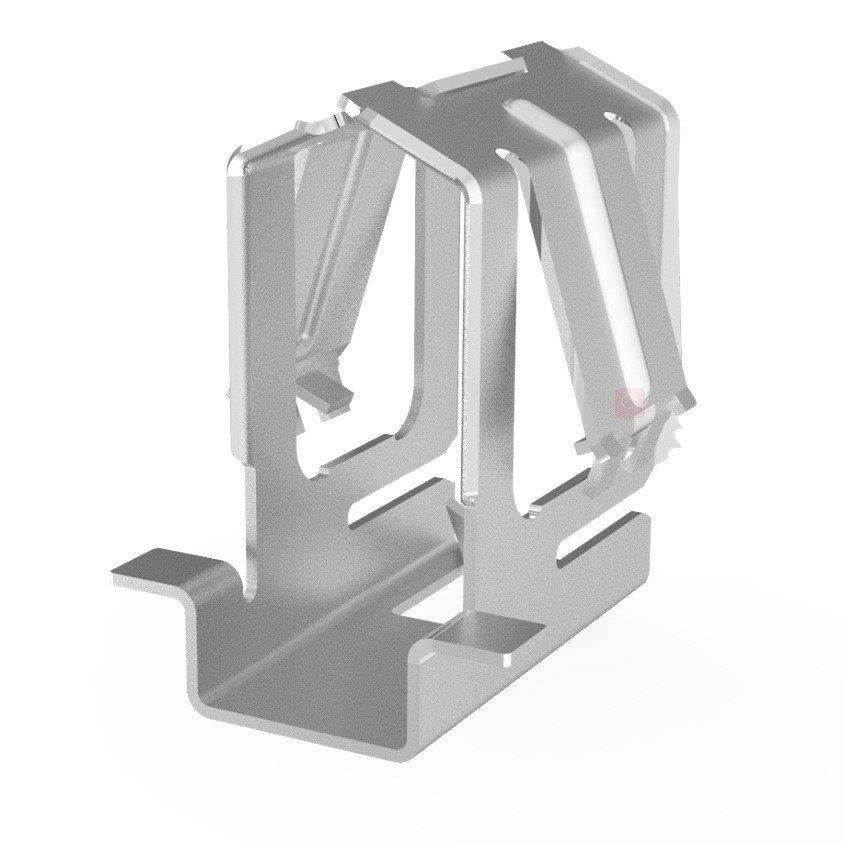

Stamping Bracket

Support your application with HY's high-quality Stamping Bracket . As a top supplier of stamped metal dies and stamped brackets, we specialize in manufacturing brackets for applications across multiple business areas.Brackets, also known as hangers, play a key role in medicine, industry, electronics, and various applications. They serve a variety of purposes such as supporting loads, securing partsMetal Natural Gas Stamping

HY high-grade Inconel Part Stamping manufacturer and supplier, HY OEM high-precision metal natural gas stamping valves and accessories, fasteners, washers.motor mount

Xiamen Hongyu Intelligent Technology Co., Ltd. is a leading manufacturing and processing plant with 17 years of processing experience and a mature import and export qualification certification system. We are committed to providing high-standard and high-performance high-quality motor mount auto parts, making us competitive in the global market.

Product type: motor mount

Quality: 100% professional quality inspection

Customization service: support OEM/ODM customizationscalpel blades

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional and reputable integrated manufacturing and trading company with many years of experience in various medical and laboratory fields. HY has established extensive and stable cooperative relations with many customers at home and abroad, with footprints in Europe, the United States, the Middle East and Russia, and can provide you with one-stop medical and laboratory product services.

Type: scalpel blades

Features: removable and replaceable, complete specifications

Material: carbon steel, stainless steelCheck Valve

Xiamen Hongyu Intelligent Technology Co., Ltd. has more than 17 years of processing and production experience, and has rich experience in the design and manufacture of various types of Check Valves and valve drive devices. HY's main products include: nuclear power valves, power station valves, fire water supply valves, chemical valves, petroleum valves, etc.

Type: Check Valve, 3 flanged check valve, swing check valve

Material: Stainless steel

Working pressure: 150 pounds 300 pounds, can support customizationDie Casting Exhaust Pipe

HY is a factory that Die Casting Exhaust Pipe exhaust pipes for automobile parts.Hongyu custom-designed aluminum die-cast motorcycle exhaust pipes, die-cast aluminum five-axis machine-made racing exhaust pipes, motorcycle mufflers, car exhaust pipes.