- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Stamping nail lamp housing Manufacturers, Suppliers, Factory

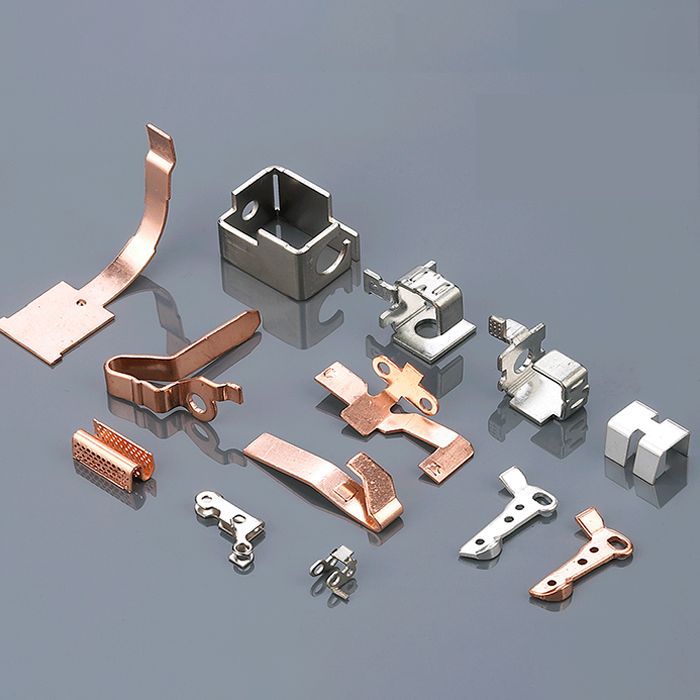

It adheres to the tenet ""Honest, industrious, enterprising, innovative"" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Stamping nail lamp housing,LED Nail Lamp shell,led nail lamp metal shell,nail lamp metal shell,nail dryer lamp metal shell, Welcome your enquiry, most effective service will likely be provided with full heart.

Stamping nail lamp housing, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing solutions, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Hot Products

Motorcycle Cylinder

Xiamen Hongyu Intelligent Technology Co., Ltd.'s Motorcycle Cylinders are manufactured using a high-pressure die-casting method to ensure the highest precision and strength. They are made from high-quality materials and are durable, providing excellent performance and durability. With a variety of sizes and designs to choose from, we have the perfect solution for any motorcycle enthusiast.

Material: Aluminum Alloy, Customization Supported

Color; Metallic Color, Silver

Type: Motorcycle CylinderStamping Wire and Cable Connectors

HY is a professional Stamping Wire and Cable Connectors manufacturers and suppliers in China. Precision manufacturing of stamping wire and cable connector components is critical because debris or loose connections can create gaps or drag between the module and the cable or wire.oil sump

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional auto parts manufacturer that produces oil coolers, intake manifolds, engine valve covers, and oil sump engine accessories. At present, it has many cooperative customers in the United States, Europe, Russia and other regions.

Product name: oil sump

Material: aluminum, stainless steel, titanium, special alloys, etc.

Application scenarios: automotive industry, industrial equipment manufacturingSelective Plated Terminals

HY is a factory that Selective Plated Terminals progressive high-speed stamping dies.OEM metal progressive high speed stamping die for selective plated terminals part/press machine/electrical jack metal part/electrical appliance metal hook buckle。Energy Vehicle Charging Gun Housing

HY is a manufacturer and supplier of Energy Vehicle Charging Gun Housing. HY precision metal stamping mold new energy vehicle charging gun stamping parts specifications: 1. The material is phosphor bronze C5191. Material thickness is 0.3mm. 2. Support surface treatment: silver plating, gold plating, nickel plating or chrome plating. 3. The seams of the stamped parts are tightly combined, without deformation, overlap, or gaps. In the drop test from a height of 2 meters in any direction, the components were not damaged.Camera Bracket

Manufacturing process: die casting, Camera bracket material: aluminum, Thickness: can be customized, Accuracy: 0.005 mm, Application areas: various hardware supports, Functional features: Support fixed metal state: Semi-solid die-casting.