- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Metal Stamping Components Manufacturers, Suppliers, Factory

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for Metal Stamping Components,Metal Stamping Suppliers,Stamped Fastener,Custom Metal Stamping Services,Precision Metal Stamping, We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

Metal Stamping Components, It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Hot Products

Die Casting Mechanical And Electrical Shroud Fan

HY Zinc alloy Die Casting Mechanical And Electrical Shroud Fan factory. Part material: Zamak 2/3/5/7 Industry: Home appliance industry, electromechanical industry Number of chambers: 1*1, 1*2auto battery tray

Xiamen Hongyu Intelligent Technology Co., Ltd. has been committed to the development of low-voltage components, lighting components, automation components, medical equipment components, communication components and precision equipment components. We have been committed to stamping and assembly production for many years. We have accumulated rich experience in the field of auto battery tray. Our products are widely used in various high-power battery packs, electric vehicle battery packs, solar street lights, military battery packs, etc., which can meet the needs of most customers. The battery trays produced by HY have different shapes and standards. We can provide customized technical services for various application scenarios according to customer needs.

Process: aluminum stamping, aluminum extrusion, precision machining, welding assembly

Surface treatment: spraying, black, galvanizing

Application scenarios: automobiles, electric vehicles, ships, etc.Inconel Part Oil Stamping

HY is a manufacturer and seller of custom Inconel Part Oil Stamping, Inconel part stampings are used in the petroleum industry and are very popular.Crimp Connectors

Xiamen Hongyu Intelligent Technology Co., Ltd. supports the customization of standard/non-standard parts of Crimp Connectors, and has more than 17 years of professional technology in hardware mold design and stamping product production. The minimum processing thickness of Crimp Connectors can reach 0.08mm, with excellent craftsmanship and no burrs.

Hongyu's advantages:

1. The selected materials far exceed the national standards

2. The service life of Stamping hardware terminals can reach more than 100,000 times

3. The durability of Crimp Connectors can reach more than 20,000 plug-in and pull-out times

4. Anti-oxidation/anti-fatigue/good rigidity/high precisionStator And Rotor

Xiamen Hongyu Intelligent Technology Co., Ltd. can provide most products in the motor industry, such as stepper motors, DC brushless motors, servo motors, including stator and rotor, electric push rods and other related accessories. HY can customize products and production lines according to customers' industries, such as medical, industrial control, robots, robotic arms, etc.

Product name: rotor stator

Type: brushless motor

Torque: 0.3Nm

Certification: ISO9001, ISO14001, CE, ROHS, CCC

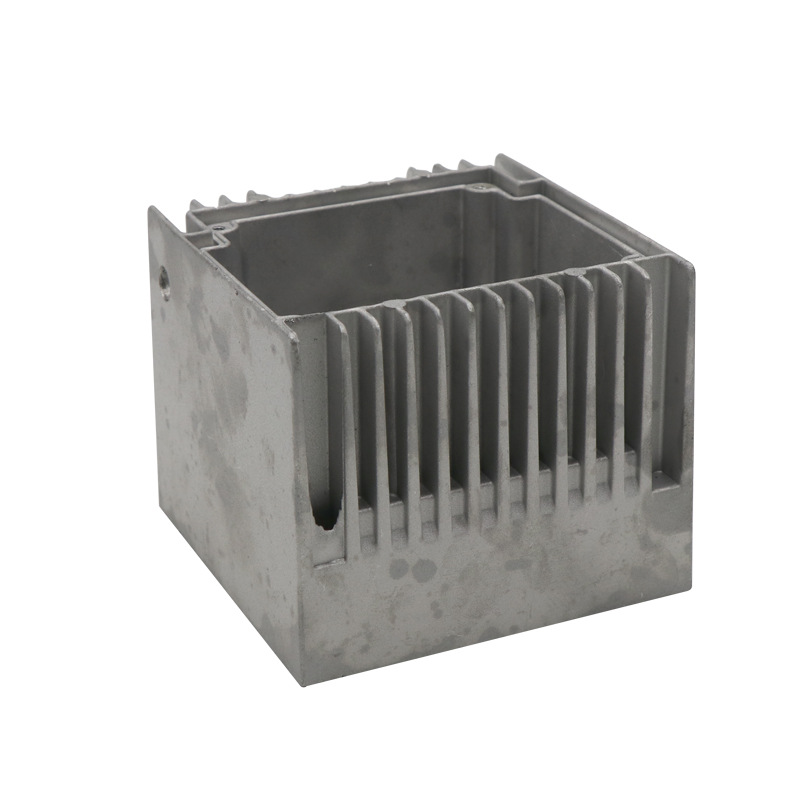

Customization: support customizationHeat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.