- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Fuse Clips Manufacturers, Suppliers, Factory

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Fuse Clips,Metal Fuse Clips,Stamped Fuse Clips,Electrical Fuse Holders,High Voltage Fuse Clips, Never-ending improvement and striving for 0% deficiency are our two main good quality policies. Should you need anything, do not hesitate to call us.

Fuse Clips, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Hot Products

Meat Grinder Screw

As a leading manufacturer of meat grinder die-casting parts, HY specializes in the production of high-quality meat grinder screws. HY's screws provide precision and efficiency while ensuring perfect grinding every time. Our meat grinder screws are made of high-quality materials, making them durable and reliable even in the most demanding conditions.Zinc Die-Cast Door Handle

Product name: Precision machining of zinc die-cast door handle

Material: Zinc alloy

Product Name: Precision machined zinc die-cast door handle

Usage: Train door handles, construction decoration door handles

Sample: 42 days for mold opening + proofingmedical wheelchair

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production and supply of high-quality medical care products. HY has established a good reputation through high-quality and professional production, quality control and customer service. We provide a variety of hospital or home care products, including wheelchairs, trolleys, bathroom series, walkers, crutches and beds, etc.

Product type: medical wheelchair

Material: carbon steel, aluminum alloy, stainless steel, carbon fiber

Processing method: precision stamping

Load limit: 136KG

Recommended population: patients with impaired walking function, the elderly, patients in rehabilitation periodMetal Stamping Construction Industry Support

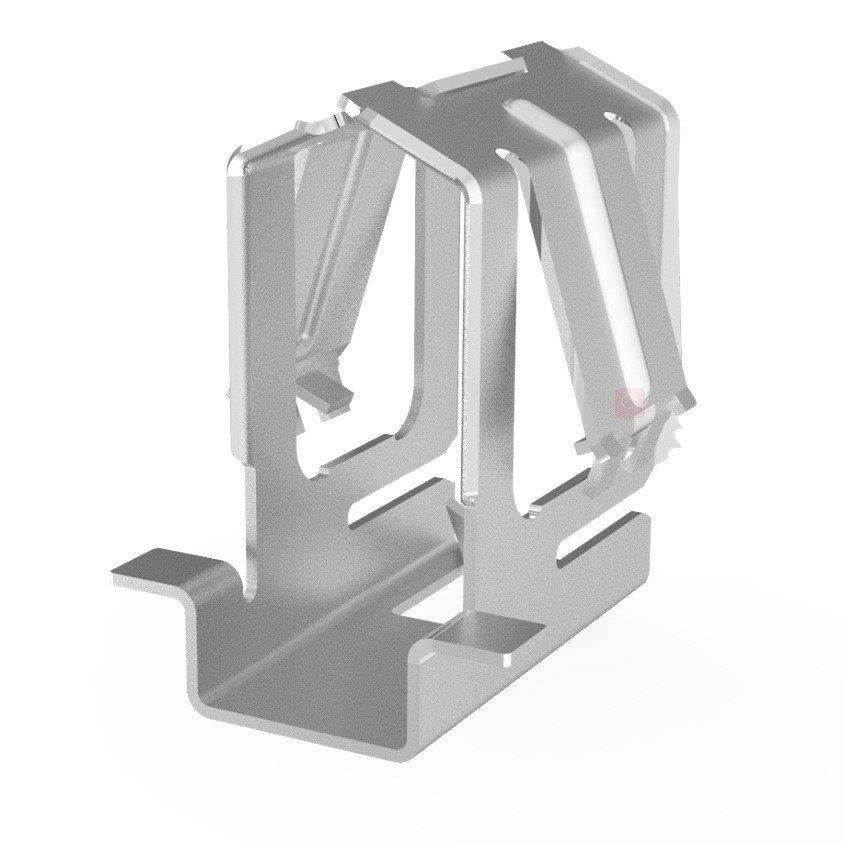

HY is an experienced manufacturer of metal stamping construction industry support, the use of metal continues to increase in commercial buildings and even residential construction. Metal is a durable material that resists corrosion, decay, and structural stress more effectively than wood and other types of building materials.Stamping Wire Formed Fasteners

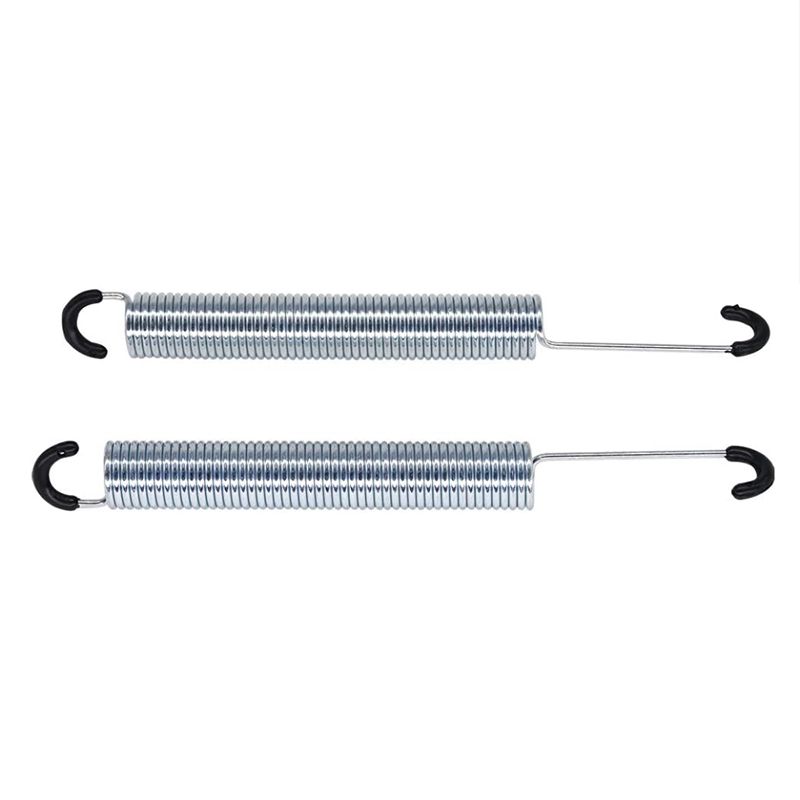

HY is a factory that Stamping Wire Formed Fasteners wire formed fasteners .Wire forming is the process of shaping metal wire into useful parts such as springs, wire formed fasteners and retaining rings.Building Fasteners

Xiamen Hongyu Intelligent Technology Co., Ltd. has been a reliable manufacturer of high-quality Building Fasteners and various metal stampings that meet DIN/ISO/ANSI/BS/JIS standards or customer specifications. HY always checks the stamping manufacturing with high reputation and quality standards. Thanks to the highest quality standards and personalized solutions, SSF complies with ISO9001:2015 standards. HY utilizes the latest stamping technology and manufacturing concepts to continuously provide a wide range of stampings. With more than 26,000 square meters of warehouses and more than 30 automatic punching machines, our monthly production capacity is 1,800 tons for various non-standard stampings such as furniture corners, wood connectors, pillar fittings clamps, Building Fasteners and a full set of standard flat washers.

Product Type: Die cast construction fasteners

Surface treatment: black, gray, galvanized, other

Application scenarios: home, hotel, building construction, ship, dock