- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Brass Fuse Clips Manufacturers, Suppliers, Factory

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Brass Fuse Clips,Metal Fuse Clips,Stamped Fuse Clips,Electrical Fuse Holders,Fuse Clips, Welcome your enquiry, most effective service will likely be provided with full heart.

Brass Fuse Clips, Our tenet is "integrity first, quality best". We've got confidence in providing you with excellent service and ideal solutions. We sincerely hope we can establish win-win business cooperation with you in the future!

Hot Products

Uv Nail Lamp Metal Shell

Xiamen Hongyu Intelligent Technology Co., Ltd. is one of the manufacturers specializing in the production of high-quality Uv Nail Lamp Metal Shell. You can rest assured to buy uv nail lamp metal shell from HY. We will provide you with the best after-sales service and timely delivery.

Product name: LED Nail Lamp shell

Surface treatment: sandblasting

Material: aluminum alloy

Feel: anti-fall, wear-resistant, not easy to break, smooth and texturedStamping Photovoltaic Terminals

Welcome to wholesale Stamping Photovoltaic Terminals from us,every request from customers is being replied within 24 hours. HY is a factory that specializes in customizing the production of photovoltaic terminal .The photovoltaic terminals of a photovoltaic system inverter are vital electrical connectors used to establish connections between the inverter and the various components of the photovoltaic (PV) system. They play an important role in ensuring efficient and reliable power transmission within the system.Metal Stamping Electronic Wire Assemblies

HY is a Metal Stamping Electronic Wire Assemblies factory that custom-processes metal stamped electronic wire assemblies.The industries served by HY include home appliances, electrical equipment, electronics, and lighting. Nearly 20 years of experience in Precision Metal Stamping.Casting Seeder Housing

HY's die Casting Seeder Housing are used in most different manufacturing areas, from machine manufacturing, Seeder housings and the oil and gas industry to consumer goods and decorative/artistic castings.Curtain Bracket

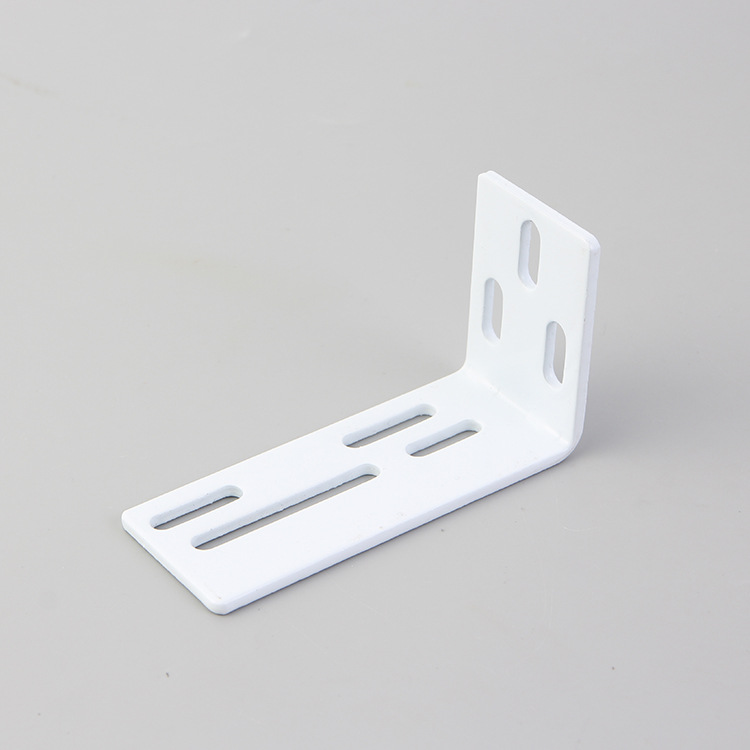

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional Stamping Curtain Bracket Supplier, using precision metal stamping technology, good quality and low price.

Product name: curtain bracket

Material: stainless steel

Process: Progressive stamping die

Type: Hardware metal stamping

Industry: hangers, brackets, curtainsmedical tweezers

Xiamen Hongyu Intelligent Technology Co., Ltd. is a manufacturing company integrating production, sales and service of medical tweezers. HY is committed to strict quality control and thoughtful customer service, 24-hour engineering docking service, and is always available to discuss your requirements and ensure complete customer satisfaction. It always implements the concept of creating value for customers and tailors products for customers.

Product type: medical tweezers

Customization service: support OEM/ODM customization service

Features: corrosion-resistant, rust-proof, support high-temperature disinfection

Material: stainless steel