- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China fuse block terminal Manufacturers, Suppliers, Factory

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for fuse block terminal,terminal stamping,Stamping hardware terminals,terminal strips,wire terminals,spade terminal,car battery terminal connectors, We will do our best to meet your requirements and are sincerely looking forward to developing mutual beneficial business relationship with you!

fuse block terminal, We are proud to supply our items to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Hot Products

Drive Shaft Assembly

Xiamen Hongyu Intelligent Technology Co., Ltd. integrates R&D, production, sales and after-sales service. Its main products include automobile drive shaft assembly (commonly known as: drive shaft), automobile constant velocity joint (commonly known as: cv joint), cv joint dust cover repair kit. In order to provide more convenient and faster service, we always reserve a large number of hot-selling models at home and abroad.

Product Name: Stamping Drive Shaft Assembly

Origin: Fujian, China

Application: Drive Shaft Connecting Parts

Special: Welcome To Customize OEM/ODM

Certificate: IATF16949, ISO14001, SGS RoHSCoffee Machine Filter

Product name: Die-cast coffee machine filter accessories

Surface treatment: polished

Manufacturing process: precision castingmedical wheelchair

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production and supply of high-quality medical care products. HY has established a good reputation through high-quality and professional production, quality control and customer service. We provide a variety of hospital or home care products, including wheelchairs, trolleys, bathroom series, walkers, crutches and beds, etc.

Product type: medical wheelchair

Material: carbon steel, aluminum alloy, stainless steel, carbon fiber

Processing method: precision stamping

Load limit: 136KG

Recommended population: patients with impaired walking function, the elderly, patients in rehabilitation periodMetal Stamping Industry Springs

Metal Stamping Industry Springs have been used as an important part of many areas of modern life. Industrial springs produced by HY are affordable. Therefore, designing springs with available diversity has become critical for both commercial products and industrial applications.Curtain Bracket

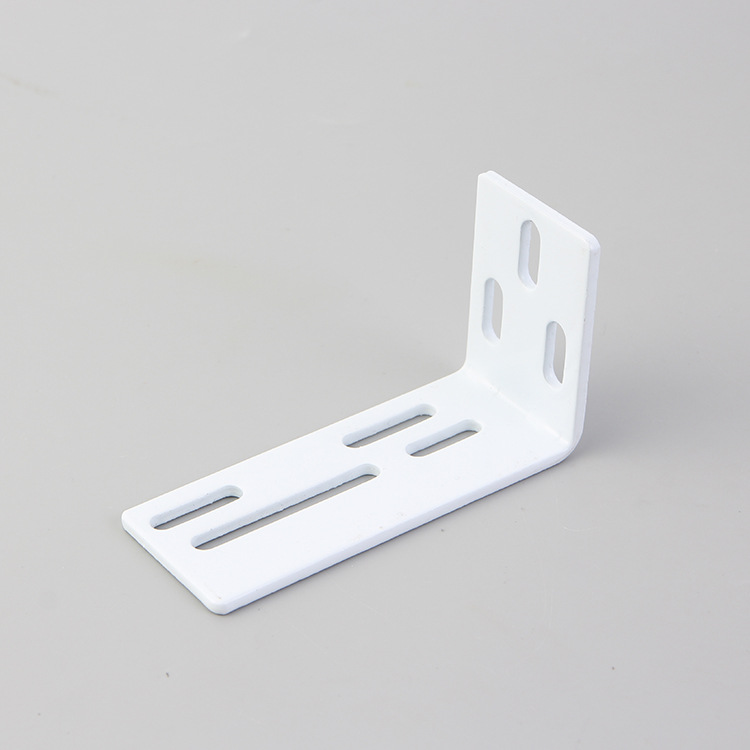

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional Stamping Curtain Bracket Supplier, using precision metal stamping technology, good quality and low price.

Product name: curtain bracket

Material: stainless steel

Process: Progressive stamping die

Type: Hardware metal stamping

Industry: hangers, brackets, curtainsMotor Housing

Xiamen Hongyu Intelligent Technology Co., Ltd. is a company specializing in the production of motor housing. HY is a professional manufacturer specializing in metal stamping, metal castings and backlog parts. Today, we have developed into a comprehensive group, providing one-stop services for production, sales and after-sales. HY always puts the quality of motor housing products first and strictly implements ISO9001 and ISO14001:2004 system standards, which enables us to keep pace with international standards.

Product type: motor housing, aluminum motor housing

Surface treatment: anodizing, sandblasting, support customization

Drawing format: AutoCAD, Solidworks, CAXA, UG, CAD