- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China crankcase Manufacturers, Suppliers, Factory

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for crankcase,crankcase splitter,motorcycle crankcase splitter,crankcase suppliers,crankcase manufacturer, We will keep working hard and as we try our best to supply the best quality products, most competitive price and excellent service to every customer. Your satisfaction, our glory!!!

crankcase, Our company mission is that providing high quality and beautiful products with reasonable price and strive to gain 100% good reputation from our clients. We believe Profession achieves excellence! We welcome you to cooperate with us and grow up together.

Hot Products

lunch box

Xiamen Hongyu Intelligent Technology Co., Ltd. has been committed to the development and production of stamping and die-casting products for many years, such as kitchen household products, stainless steel lunch box forks and spoons, lunch boxes, water cups, baby products and many other series. A company specializing in the production and processing of quality management system, honest management, quality assurance, self-production and self-sales, reasonable prices, HY has been widely praised in the European, American and Middle Eastern markets and won the trust of consumers, and has been recognized by the industry with its integrity, strength and product quality. Friends from all walks of life are welcome to visit, guide and negotiate business.

Type: lunch box, kids lunch box, stainless steel lunch box

Material: 304/316 food grade stainless steel

Customization: support OEM/ODM customizationCheck Valve

Xiamen Hongyu Intelligent Technology Co., Ltd. has more than 17 years of processing and production experience, and has rich experience in the design and manufacture of various types of Check Valves and valve drive devices. HY's main products include: nuclear power valves, power station valves, fire water supply valves, chemical valves, petroleum valves, etc.

Type: Check Valve, 3 flanged check valve, swing check valve

Material: Stainless steel

Working pressure: 150 pounds 300 pounds, can support customizationMotor Cooling Fan Blade

Motor cooling fan blade material: aluminum, Manufacturing process: die casting, Surface treatment: anodizing, powder coating, Application industry: industrial machinery, Die casting time: 100 pieces/hour,solar mounting system

Xiamen Hongyu Intelligent Technology Co., Ltd. is a high-tech enterprise specializing in the research and development, production, sales and service of solar photovoltaic support systems in the new energy industry. These products have been sold to more than 100 countries and regions including the United States, the European Union, Australia, the Middle East, South Africa, Japan and Southeast Asia, and have been recognized by customers at home and abroad. HY can produce according to national technical standards according to customer needs. All performance indicators meet national standards and can provide complete qualification certification documents. Providing customers with high-quality, cost-effective products and excellent after-sales service is our mission and commitment to customers.

Product type: solar mounting system, ground mount solar

Processing services: stamping, die-casting, bending, welding, punching, cutting

Thickness: 0.5-3.0mm or customer requirements

Length: 1m-12m or customer requirementsportable handicap ramp

Xiamen Hongyu Intelligent Technology Co., Ltd. is a professional aluminum alloy manufacturer. The company has its own independent technical research and development capabilities, perfect manufacturing processes and sound quality control systems. It specializes in providing portable handicap ramp for residential and commercial places, and provides customized barrier-free solutions for people with limited mobility. It covers an area of 4,500 square meters and supplies more than 15 tons of raw materials per month. HY has obtained a number of Chinese utility model patents, appearance patents, EU appearance patents, CE safety certification, ISO9001:2015 and ISO13485 certificates.

Our main products are divided into two categories:

1. Barrier-free medical rehabilitation aids: crutches, bathing chairs, commode chairs, walkers, etc.

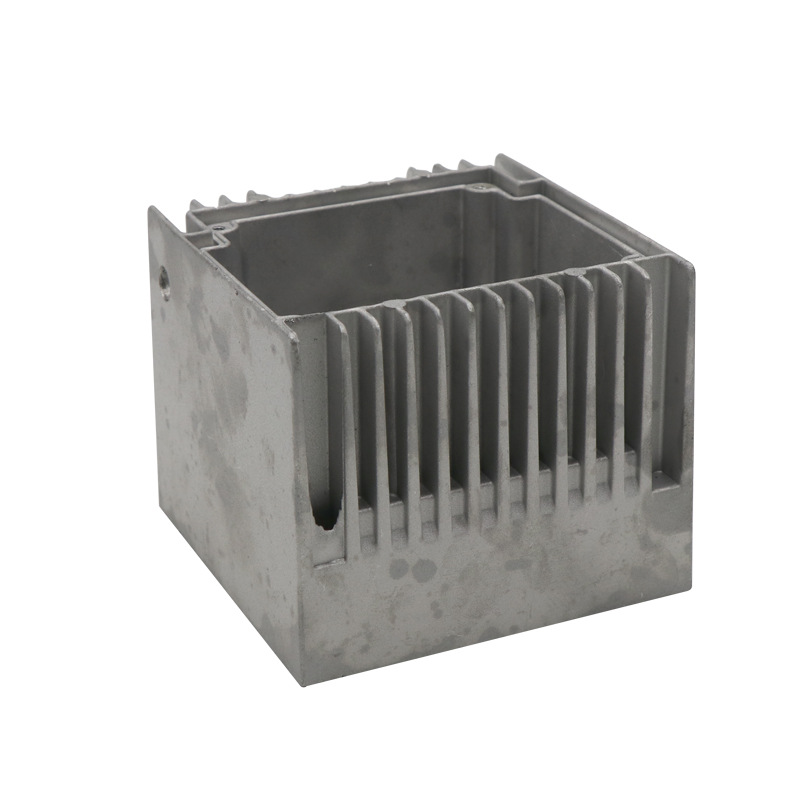

2. Aluminum alloy barrier-free ramps: folding ramps, rolling circular ramps, portable disabled ramps, etc.Heat Sink

The Heat Sink produced by Xiamen Hongyu Intelligent Technology Co., Ltd. is mainly made of aluminum die casting. HY, as an Aluminum die casting heat sink factory, has 17 years of manufacturing experience in this industry. A heat sink is a heat exchanger that transfers heat from a heating device or heat source to the surrounding fluid, usually made of copper or aluminum. Material: 6000 series, such as alloy 6063/6061/6005, etc. Shape: square, round, support customization Color: silver, black, gold, champagne, support customization Application scenarios: IC circuit boards, motherboards, transistors, etc.