- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

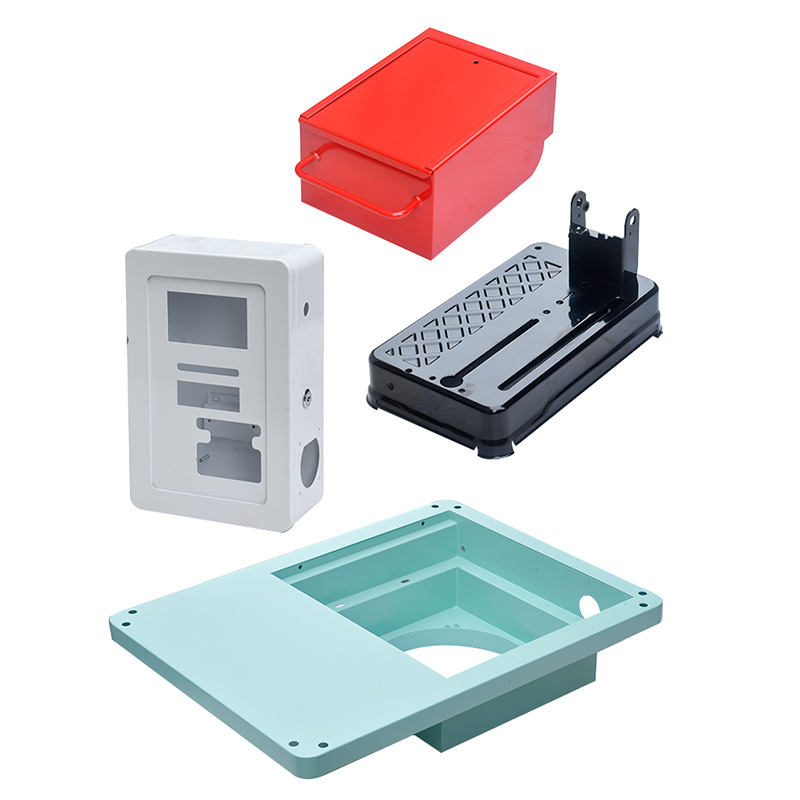

China crankcase manufacturer Manufacturers, Suppliers, Factory

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for crankcase manufacturer,crankcase,crankcase splitter,motorcycle crankcase splitter,crankcase suppliers, Sincerely hope we're increasing up along with our buyers all around the entire world.

crankcase manufacturer, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you want.

Hot Products

Casting Engine Components

HY supplies Casting Engine Components to European and American customers and is a global factory supplier. Today's engines and engine components require lightweight, high strength, pressure resistance and high machinability. Aluminum engine casting offers all of these advantages, improving engine performance while providing additional advantages over traditional construction.Die Casting Lower Cover

HY is a manufacturer and supplier of cast lower covers, using presses from 25 tons to 400 tons, and can meet customer needs whether it is precision or large Die Casting Lower Cover.Barbecue Grill

Xiamen Hongyu Intelligent Technology Co., Ltd. has 17 years of processing and manufacturing experience and is China's leading Outdoor Portable Barbecue Grill Manufacturer. HY's BBQ grill stamping parts are sold to dozens of countries at home and abroad. We are committed to improving our product quality and service system through continuous innovation and after-sales. In order to meet the needs of every family, we welcome OEM business. Stamping type: metal stamping processing Grill material: stainless steel plate Processing type: metal forming Process: stamping, bending, trimming, forming, blanking Surface treatment: electroplating Proofing cycle: 8-15 daysBuilding Fasteners

Xiamen Hongyu Intelligent Technology Co., Ltd. has been a reliable manufacturer of high-quality Building Fasteners and various metal stampings that meet DIN/ISO/ANSI/BS/JIS standards or customer specifications. HY always checks the stamping manufacturing with high reputation and quality standards. Thanks to the highest quality standards and personalized solutions, SSF complies with ISO9001:2015 standards. HY utilizes the latest stamping technology and manufacturing concepts to continuously provide a wide range of stampings. With more than 26,000 square meters of warehouses and more than 30 automatic punching machines, our monthly production capacity is 1,800 tons for various non-standard stampings such as furniture corners, wood connectors, pillar fittings clamps, Building Fasteners and a full set of standard flat washers.

Product Type: Die cast construction fasteners

Surface treatment: black, gray, galvanized, other

Application scenarios: home, hotel, building construction, ship, dockTransmission Lead-Frames

HY is a professional Transmission Lead-Frames manufacturers and suppliers in China, If you manufacture rice cookers, dryers, refrigerators, and other appliances, you rely on small components such as transmission lead frames manufactured by the best appliance stampings suppliers. This is where HY Corporation can help.Aluminum Flange

Xiamen Hongyu Intelligent Technology Co., Ltd. specializes in providing a series of products such as aluminum flanges, elbows, and pipe fittings. We will use different materials for processing according to the customer's usage scenarios and needs, such as stainless steel, carbon steel, alloy steel, etc. The products are widely used in petroleum, chemical, machinery, electricity, metallurgy, etc. The company's products support material, specification model, non-standard drawings, and customized packaging.

Processing technology: forging and casting

Keywords: ductwork flange

Application: pipeline connection

Flange type: slip-on welding flange